Ever wondered what drives efficiency and precision in today’s nail manufacturing industry? This innovation is linked to wire coil machines, a key in modern nail production that transforms the business approach.

With extensive experience in the nail production industry and a deep understanding of wire coil machine technology, I offer insights that can transform the manufacturing process and boost productivity.

Wire coil machines are redefining the nail production landscape, offering unparalleled speed, accuracy, and reliability. Their role is essential in meeting the growing demand for quality nails.

In this ultimate guide, we’ll delve into the world of wire coil machines, exploring their features, advantages, and how they integrate into the nail production process to optimize output and reduce costs.

Read on to uncover more!

1. Understanding Wire Coil Machines

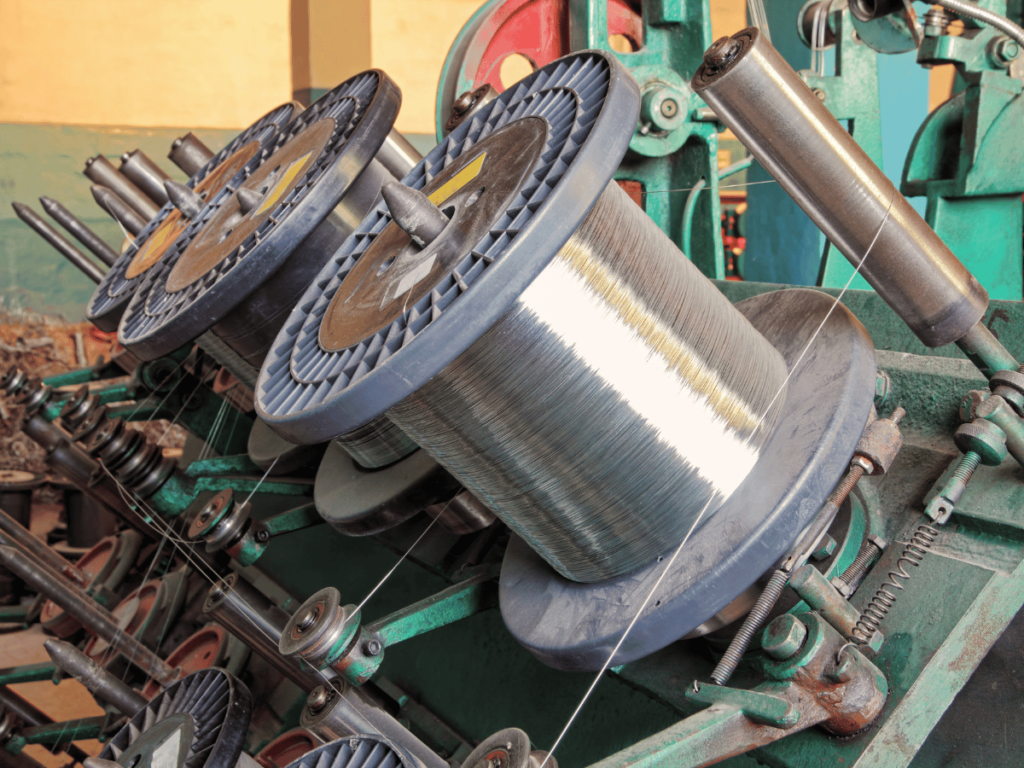

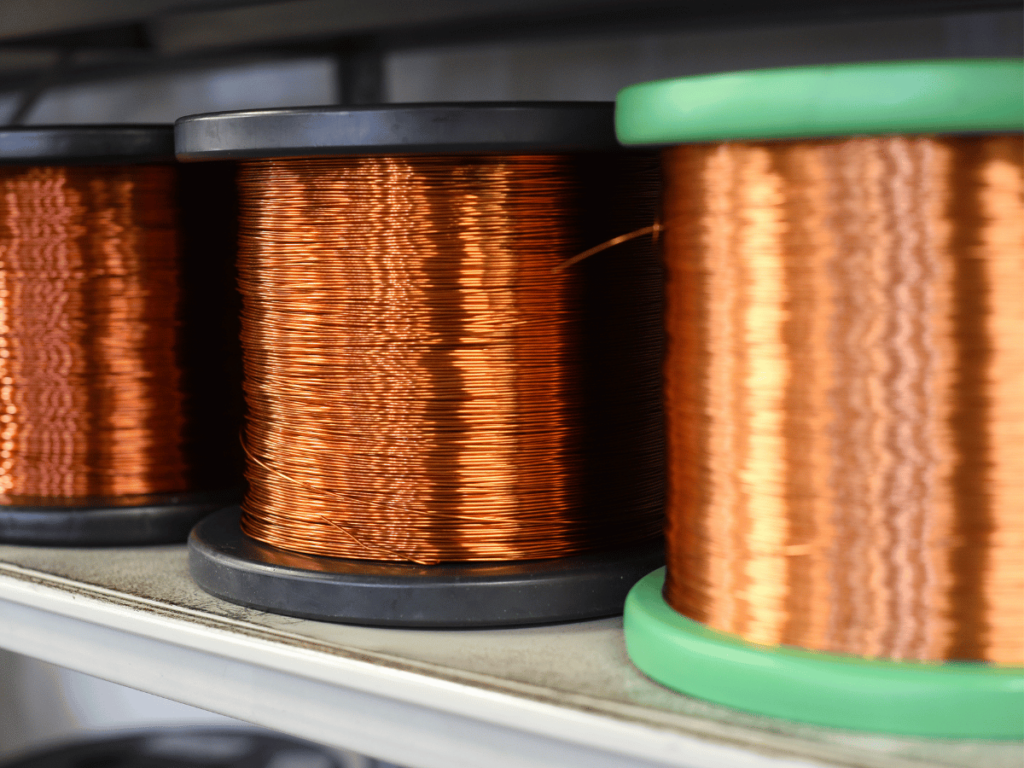

Wire coil machines are integral to nail production, streamlining the process with remarkable efficiency. Essentially, these machines convert long steel wires into precise, uniform nails. The process starts with feeding a spool of wire into the machine. This wire is then straightened, cut to length, and shaped into a nail with a pointed end and a flattened head.

Advanced models incorporate sensors and automation, ensuring each nail meets exact size and shape specifications. The result is continuous high-speed production of nails, greatly reducing manual labor and material waste. This efficiency not only accelerates production but also ensures consistent nail quality, a critical factor in meeting industry standards and client expectations.

2. Advantages of Wire Coil Machines in Nail Manufacturing

Advancing from the basic understanding of wire coil machines, let’s delve into their significant advantages in nail manufacturing:

- Increased Production Speed: Wire coil machines are designed for high-speed production. They dramatically reduce the time taken to manufacture nails compared to traditional methods,enabling businesses to fulfill large orders quickly and efficiently.

- Consistent Quality and Precision: These machines ensure each nail is produced with uniformity in size and shape. This consistency is crucial for maintaining quality standards, reducing the likelihood of defective products, and ensuring customer satisfaction.

- Cost-Effectiveness: By automating the nail production process, wire coil machines minimize labor costs and material wastage. This efficiency translates into lower production costs and higher profit margins for businesses.

- Versatility in Production: Wire coil machines can be adjusted to produce nails of various sizes and types, offering manufacturers the flexibility to cater to diverse market demands without needing multiple machines.

- Ease of Operation and Maintenance: Modern wire coil machines are user-friendly and require minimal maintenance.This ease of operation allows for quick training of personnel and less downtime for maintenance, ensuring uninterrupted production.

3. Innovation and Technological Advances in Wire Coil Machines

After understanding the advantages of wire coil machines, what comes next is innovation and technological advances. Let’s explore how they have further enhanced their capabilities in the nail manufacturing industry:

Enhanced Automation and Control Systems

The introduction of advanced automation in wire coil machines marks a significant leap in manufacturing efficiency. These systems enable precise control over every aspect of nail production, from wire feeding to nail shaping and cutting. Automated control systems ensure consistency in production, regardless of the volume. For example, a wire coil machine might now feature a programmable logic controller (PLC) in the settings.

Integration of IoT and Smart Technologies

The integration of the Internet of Things (IoT) and smart technologies in wire coil machines is transforming nail manufacturing into a data-driven industry. These technologies enable the real-time monitoring of machine performance and production metrics. Awnail, known for offering cost-effective machines, is increasingly incorporating these smart technologies to offer better value and efficiency to its clients.

Customization and Modular Design

The trend towards customization and modular design in wire coil machines is a response to the diverse needs of nail manufacturers. Machines are now being designed with modular components, allowing for easy customization to suit specific production requirements. As an example, this flexibility means that manufacturers can adapt their machines to different types of nails, materials, or production scales.

4. The Manufacturing Process: From Wire to Nail

As we examine the impact of technological innovations on the industry, let’s now focus on the detailed manufacturing process of transforming wire into nails. Here are some to take note of:

Step#1 Wire Drawing

The first step in nail manufacturing is wire drawing, where a thick steel wire is drawn through a series of dies to reduce its diameter to the desired size for nails. This process is crucial for determining the strength and flexibility of nails. Modern wire coil machines like those from Awnail, are equipped with precision drawing capabilities ensuring that the wire is of uniform thickness and quality.

Step#2 Wire Straightening and Cutting

Once the wire is drawn to the correct diameter, it needs to be straightened. Wire coil machines efficiently straighten the wire using rollers or straightening dies, eliminating any bends or coils. The straightened wire is then cut into predetermined lengths, corresponding to the desired nail size. This step is critical for ensuring that each nail is uniform in length, an essential quality standard in the industry.

Step#3 Pointing

The next step involves shaping one end of the cut wire into a sharp point. In this stage, the wire is fed into a machine where a series of dies to shape the end into a tapered point. This process must be precise to ensure that the nail can be easily driven into materials without bending or breaking. Advanced machines handle this task with great accuracy and speed, enhancing the overall efficiency of the production line.

Step#4 Heading

The opposite end of the wire is then processed to form the nail head. This is achieved through a heading process where the wire is clamped and a portion of it is formed into a flat or rounded head. The heading process is crucial for the nail’s functionality, as the head provides a surface for the hammer to strike. Wire coil machines are designed to produce nail heads with consistency, an important factor in ensuring nail usability.

Step#5 Finishing and Quality Control

The final step involves finishing treatments such as polishing, coating, or galvanizing, depending on the nail’s intended use. These treatments enhance the nail’s resistance to corrosion and improve its aesthetic appeal. After finishing, nails undergo strict quality control checks to ensure they meet the required standards. Wire coil machines are instrumental in this phase, often featuring integrated quality control systems to detect issues.

Here’s a table that outlines the aspects of finishing and quality control in the nail manufacturing process:

| Stage | Process Description | Purpose and Benefit |

| Finishing Treatments | Polishing, coating, or galvanizing to prepare the nail for its intended use. | Enhances corrosion resistance and improves aesthetic appeal. |

| Quality Control Checks | Conducted after finishing to ensure nails meet required standards. | Ensures the final product meets quality specifications for safety and durability. |

| Wire Coil Machines | Utilized in the finishing phase, often with integrated quality control systems. | Detects issues automatically, enhancing the efficiency of quality assurance. |

5. Challenges and Solutions in Wire Coil Machine Operation

Having explored the process from wire to nail, it’s essential to understand the challenges faced during wire coil machine operation and the solutions that can be implemented to overcome these issues. See the following:

Maintenance and Downtime

Regular maintenance is crucial for wire coil machines, but it can lead to significant downtime. Over time, components like dies and cutters wear out affecting the quality of nails produced. This maintenance is necessary but can halt production, impacting output and deadlines.

Solutions: By adopting a predictive maintenance approach, using sensors and data analytics, manufacturers can anticipate wear and tear, scheduling maintenance without significantly disrupting production. This proactive approach minimizes unexpected downtime.

Material Wastage

Even with advanced technology, material wastage is a concern. Incorrect machine calibration or operational errors can lead to excessive wire usage or the production of defective nails, contributing to higher production costs.

Solutions: Modern wire coil machines come with advanced controls for precise material usage. Implementing tight operational controls and regular calibration checks can significantly reduce material wastage. Additionally, using recycled materials where possible can offset raw material costs.

Training and Skilled Labor

Operating wire coil machines requires skilled labor. The complexity of newer, more advanced machines means that operators need comprehensive training, which can be a challenge in terms of time and resources.

Solutions: To combat the skills gap, manufacturers should invest in comprehensive training programs for their staff. This investment not only enhances the efficiency of machine operation but also ensures the longevity and optimal use of the equipment.

Adapting to Varied Production Requirements

Meeting diverse market demands can be challenging. Manufacturers often need to produce various types and sizes of nails, requiring frequent adjustments and recalibrations of the machines, which can be time-consuming and technically demanding.

Solutions: Choosing machines with modular designs and quick changeover capabilities can ease the process of switching between different nail types and sizes. This flexibility allows manufacturers to swiftly adapt to varying production requirements efficiently.

6. The Impact of Wire Coil Machines on Production Efficiency

After addressing the challenges and solutions to wire coil machine operation, let’s see the profound impact these machines have on production efficiency in the nail manufacturing industry. Here are some:

Increase in Output

The primary impact of wire coil machines is the substantial increase in production output. Traditional nail making methods are labor-intensive and time-consuming, limiting the volume of production. In contrast, wire coil machines automate key processes, enabling manufacturers to produce thousands of nails per hour. This automation means that orders, even in large quantities, can be fulfilled much faster than before.

Consistency and Quality Control

Another significant impact of using wire coil machines is the consistency in the quality of nails produced. Manual production methods are prone to human error, resulting in inconsistencies in nail sizes and shapes. Wire coil machines, however, ensure that every nail is uniform meeting strict quality standards. This consistency is crucial for manufacturers who supply to industries where precision is paramount.

Reduction in Labor and Operational Costs

Wire coil machines also play a crucial role in reducing labor and operational costs. The automation of the nail production process reduces the need for a large workforce, thereby cutting down on labor costs. Additionally, these machines are designed to be energy-efficient and to minimize waste further reducing operational expenses. The reduction in costs makes the manufacturing process more economical and competitive.

7. Future Trends in Nail Manufacturing Technology

Reflecting on the substantial impact wire coil machines have on production efficiency, it’s intriguing to consider what the future holds for nail manufacturing technology. Here are some trends to expect in the coming years:

Automation and Artificial Intelligence

The future of nail manufacturing is likely to see an even greater emphasis on automation, with artificial intelligence (AI) playing a key role. AI can be used to optimize every aspect of the production process, from material handling to quality control. This could lead to smarter, more autonomous wire coil machines that adjust their operations in real time for maximum efficiency and minimal waste.

Eco-Friendly Manufacturing Practices

Sustainability is becoming increasingly important in all manufacturing sectors, including nail production. Future trends will likely involve the development of more eco-friendly manufacturing practices. This could include using recycled materials for nail production, implementing energy-efficient machines, and reducing waste throughout the production process. There might also be a shift towards more sustainable packaging solutions.

Advanced Material Use and Product Innovation

As technology advances, so do the materials used in nail manufacturing. Future trends could involve the use of new, high-performance materials, which is expected to grow with a CAGR of 9% to 11% from 2023 to 2028 according to Lucintel. This would expand the applications for nails, opening up new markets and opportunities.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

In summarizing our exploration of wire coil machines in the nail industry, it’s clear that these machines are essential in enhancing production efficiency, quality, and innovation. This guide provides valuable insights into optimizing manufacturing processes and staying ahead in a competitive market.

Interested in elevating your nail manufacturing business with cutting-edge wire coil technology? Awnail offers custom-made machines that meet specific needs. To know more about our offerings, contact us today.