Exceptional Wire Nail Making Machine For Your Business

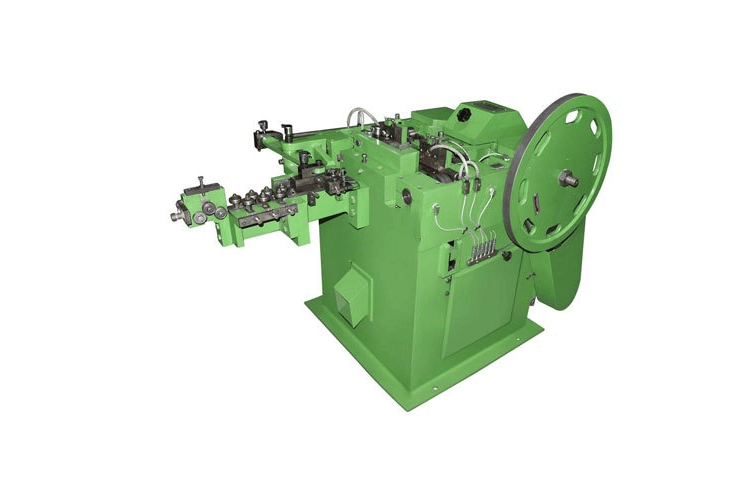

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

Inside Our Manufacturing Hub

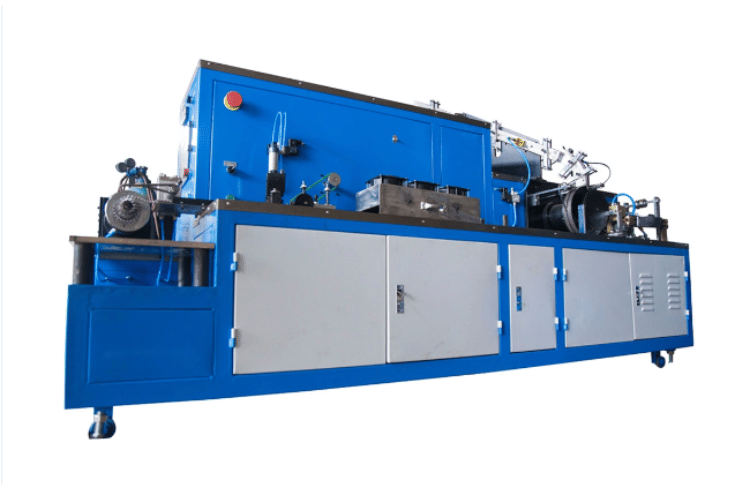

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Wire Nail Making Raw Material

Steel Wire

Copper Coating

Stainless Steel

Aluminum Wire

Wire Nail Specifications

Length and Diameter

Head Type

Shank Type

Point Type

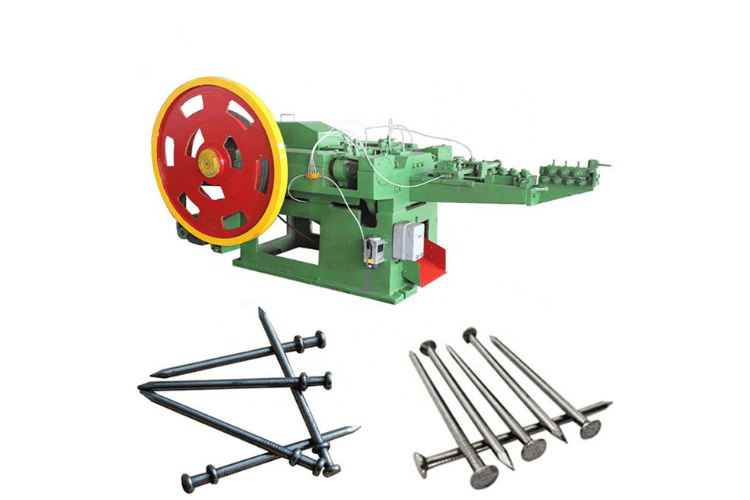

Types of Wire Nail Making Machine

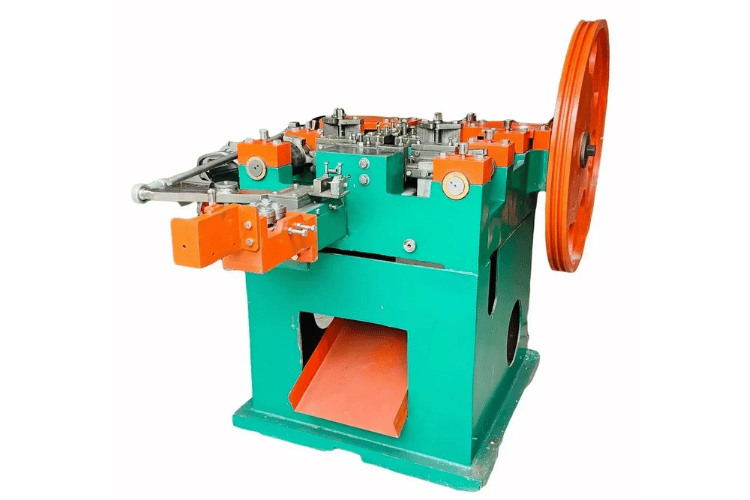

Automatic Wire Nail Making Machine

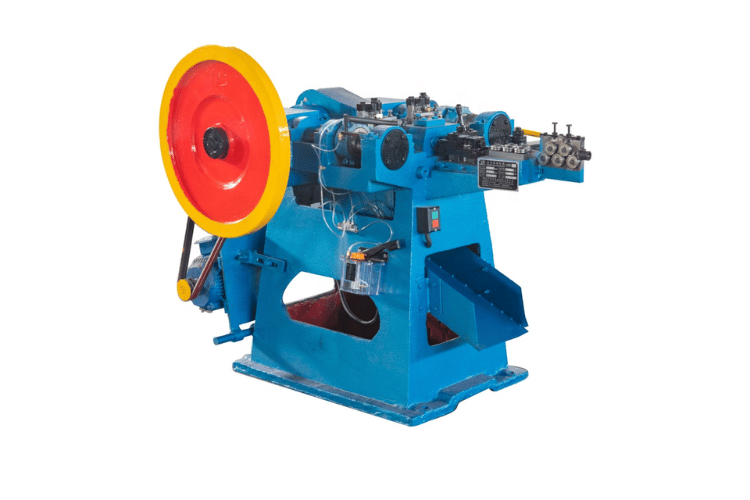

High Speed Wire Nail Making Machine

Wire Nail Making Machine Price

Cost of Wire Nail Making Machine

Features and Benefits of Wire Nail Making Machine

Features of Wire Nail Making Machine

High-Speed Operation

Advanced Automation

Versatile Nail Production

Benefits of Wire Nail Making Machine

Enhanced Productivity

Consistent Quality

Reduced Labor Costs

Applications of Wire Nail Making Machine

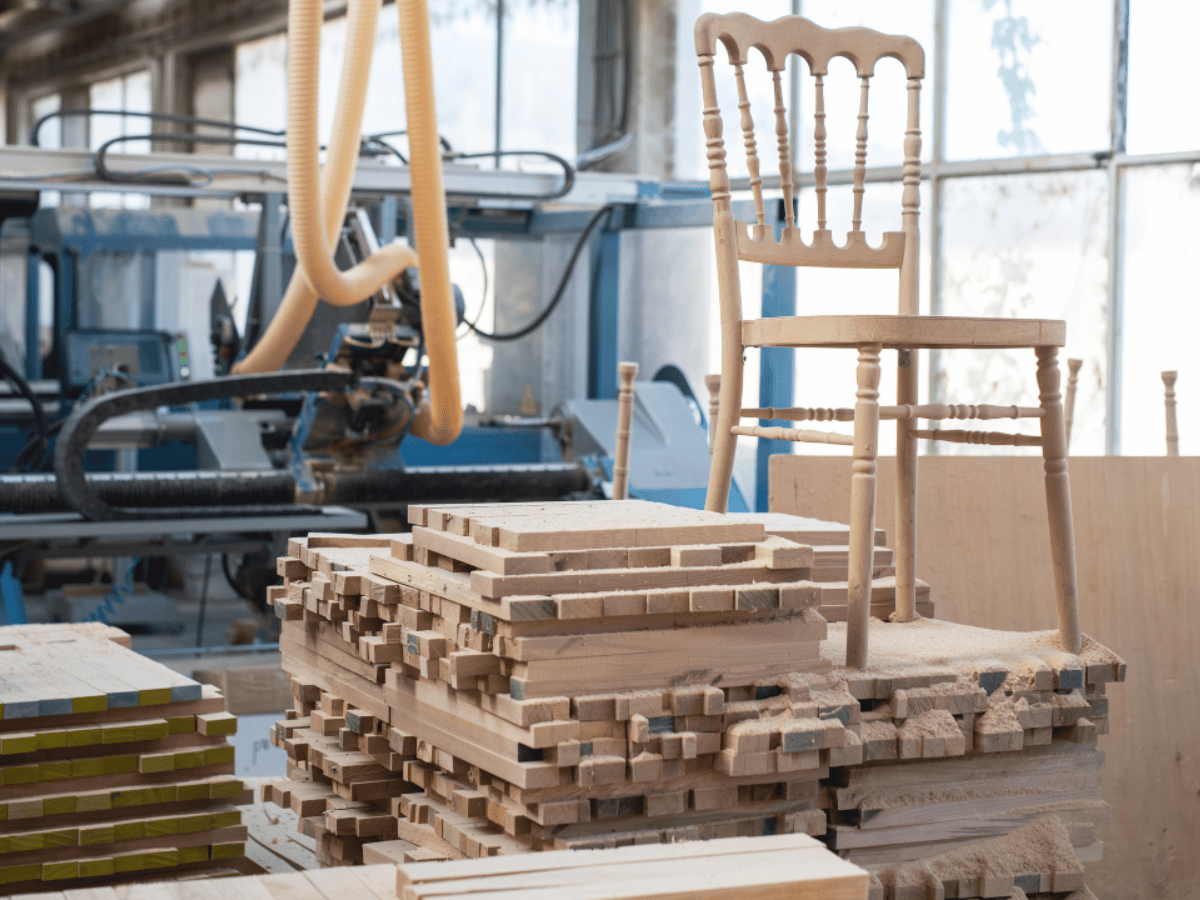

Furniture Manufacturing

Packaging Industry

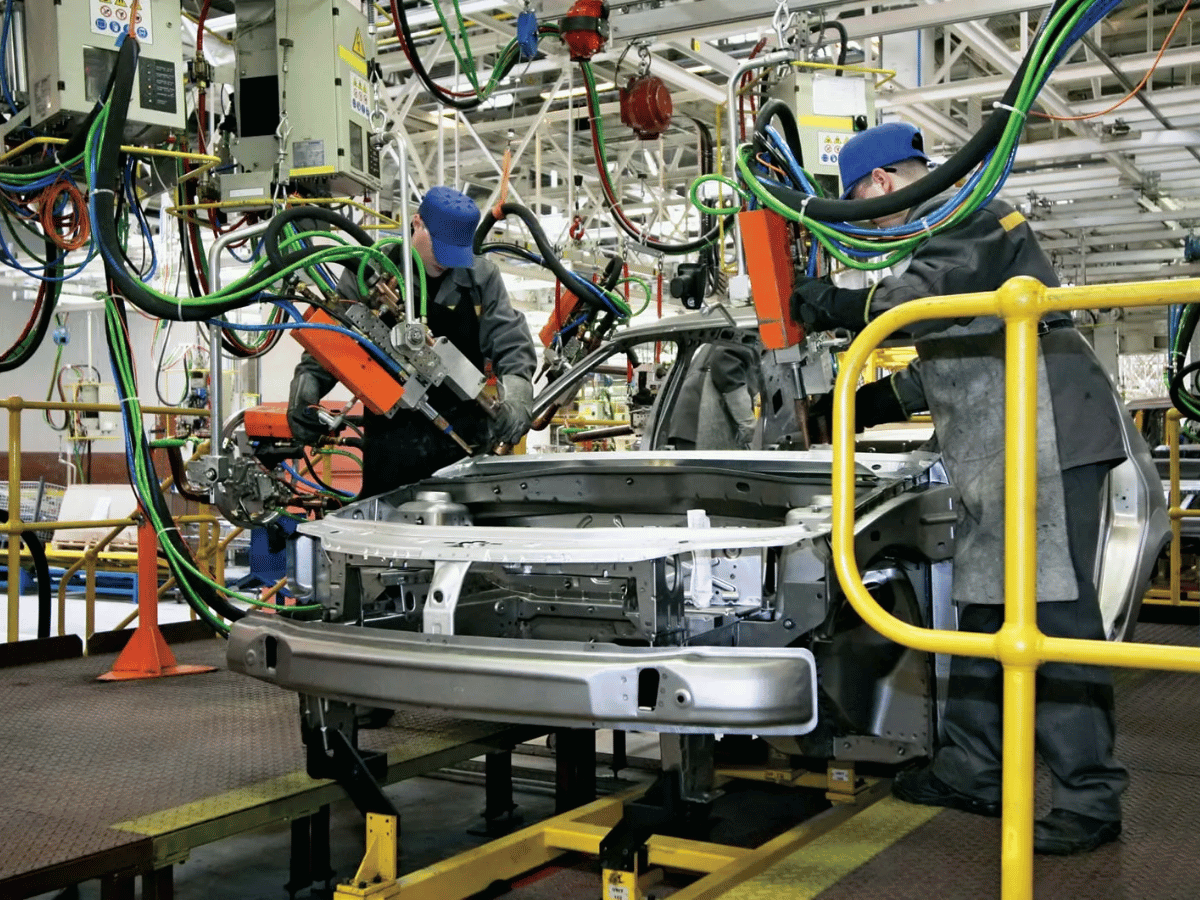

Automotive Industry

3 Considerations When Buying Wire Nail Making Machine

#1 Operational Cost

#2 User-Friendly Interface

#3 Safety Features

Dive Deeper Into Our Resources

- Meet the Top 9 Wire Nail Making Machine Manufacturers

- Everything You Need To Know About Wire Nail Manufacturing Business

Wire Nail Making Machine: How It Works and What You Need to Know

When it comes to creating a strong and sturdy construction, nails are an essential part of the process. But you’re probably wondering how they work and what you need to know before buying one.

In choosing the perfect machine for your business, you’ll have to take into consideration some the factors like the type of machine, machine size, and type of nails you will be producing.

In this post, we’ll take a look at how wire nail-making machines work and what you need to know before purchasing one. We’ll also go over some important factors to consider when purchasing a wire nail-making machine, read on!

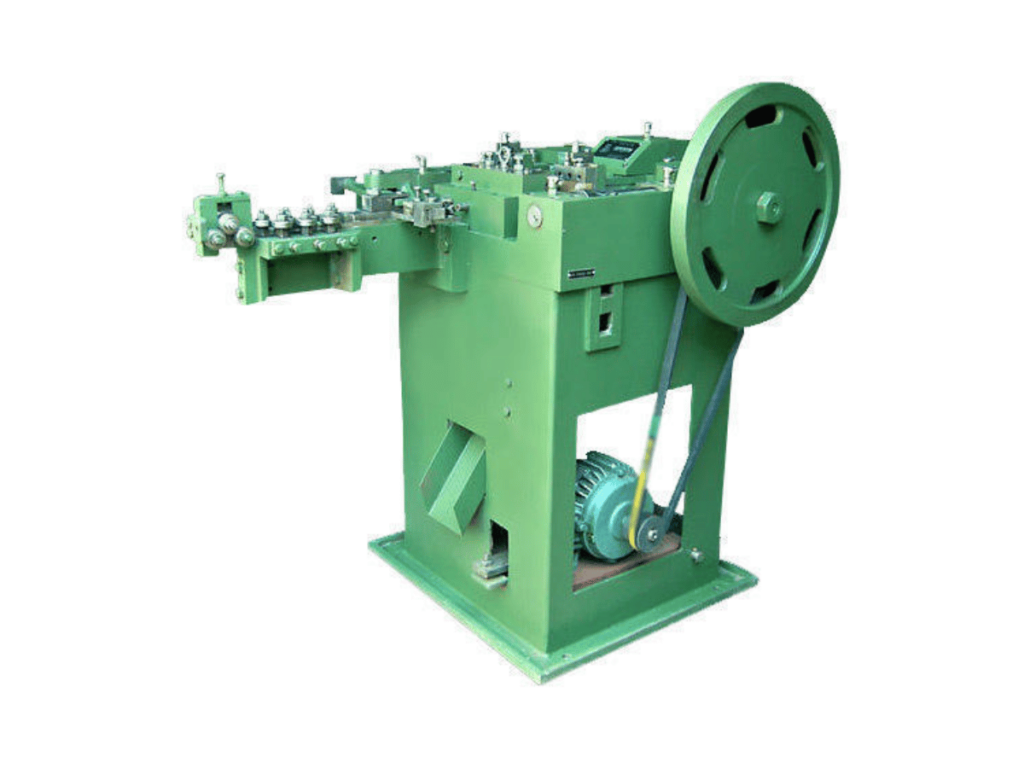

1. What Is a Wire Nail Making Machine

A wire nail-making machine is a device that is used to manufacture wire nails. It is a type of machine that is used in the manufacturing process of wire nails. Wire nails are made from metal, and the wire nail-making machine helps to create them more efficiently.

The wire nail manufacturing machine consists of several different parts that all work together to help create wire nails. Some of these parts include a feeder, a hammer, and a die. The feeder helps to feed the metal into the machine, and the hammer helps to punch it out. The die is what gives the wire nail its shape.

The wire nail machine is a very important part of the manufacturing process for wire nails, and it plays a significant role in helping to create them more efficiently.

2. How Does the Wire Nail Making Machine Work

The wire nail-making machine is a very important piece of equipment in the wire nail manufacturing process. It is used to form the nails from wire, and it can be adjusted to produce nails of different sizes.

The wire nail-making machine is a very important piece of equipment in the wire nail manufacturing process. The wire nail-making machine can be divided into two parts:

- Head: The head is used to hold the wire and the body is used to make the nails.

- Body: The body of the wire nail-making machine contains several components, including the: Anvil, Hammer, Die, and Stripper.

The wire nail-making machine is powered by a motor, which drives the hammer and dies. The speed of the hammer can be controlled to adjust the size of the nails. The wire is fed into the machine by a feeder, and the finished nails are ejected from a discharge chute.

Here’s a video on how a wire nail making machine works!

3. Different Parts of the Wire Nail Making Machine

The wire nail-making machine is composed of several different parts that work together to create wire nails. The main components of the machine are the following:

Head Former

The wire nail head former is the part of the machine that forms the heads on the nails. It consists of several rollers that press the wire against a die to create the desired shape.

Magazine

The wire nail magazine is the part of the automatic nail-making machine that holds the wire. The wire is fed into the machine by this component.

Cutter

The wire nail cutter is the part of the machine that cuts the wire. It consists of a series of blades that cut the wire to the desired length.

Point Former

The wire nail point former is the part of the machine that forms the points on the nails. It consists of a series of rollers that press the wire against a die to create the desired shape.

Extractor

The wire nail extractor is used to extract the wire nails from the polished magazine and convey them to the next stage in the manufacturing process.

If you’re interested in buying this machine, please don’t hesitate to contact Awnail team for assistance. We would be happy to answer any questions you have.

4. Materials Needed To Make Wire Nails

There are several materials you need to take into consideration before you start producing or making wire nails, and these include the following:

Wire / Coil Wire

Wire nails are made out of wire, so the first material you need is wire. The most common type of wire used to make nails is called mild steel wire.

This type of wire is strong and durable, but it can also be easily formed into different shapes. Another type of coil wire is called galvanized steel wire. Galvanized steel wire is coated with zinc to protect it from corrosion.

Nails

The nails are then fed into the wire nail machine and the wire is attached to the nails.

Wire Nail Machine

The wire nail machine is then inserted into the wire stretcher and stretched to the desired dimensions. The wire nail machines work well for making construction wire nails as long as you do not cut too much of the wire.

If you cut too much wire, it will cause your wire nail machine to stop working properly. You can also add extra wire to the wire nail machine if you need to make longer nails.

Stretcher

The wire stretcher is an important part of the wire nail machine because it helps to ensure that the wire is properly attached to the nails.

5. Step by Step Guide on How to Operate the Wire Nail Making Machine

The wire nail-making machine is a piece of machinery used to manufacture wire nails. It is a complex machine with many different parts and mechanisms.

To operate the wire nail-making machine, you must be familiar with the different parts and how they work.

Step #1 Ensure That All Components Are Lubricated

The first step in operating the wire nail-making machine is to ensure that all of the components are properly lubricated. The machine requires a lot of lubrication to run smoothly.

Step #2 Set up Machine for Production

The next step is to set up the machine for production. This includes loading the wire into the feeder, setting the guide dogs, and adjusting the pressure.

Step #3 Start Machine for Production

Once the machine is set up for production, you can start it up by turning on the power switch. The machine will start to run and the wire will be fed into the dies. The nails will then be cut and ejected from the machine.

Step #4 Remove Finished Nails

The final step is to remove the finished nails from the ejection chute. You can do this by hand or using a pneumatic conveyor. Once the nails are removed, you can start production again by repeating the steps above.

Operating the wire nail-making machine can be a complex process, but with a little practice, you will be able to do it like a pro. Follow these simple steps and you’ll be producing high-quality nails in no time!

6. Precautions Before Using The Wire Nail Making Machine

The wire nail-making machine is a device used to create nails from the wire. Before using the machine, it is important to read the manufacturer’s instructions and safety guidelines.

Here are some precautions for operating the wire nail making machine:

Make Sure the Wires Are Aligned

It’s important to make sure that the wire is properly aligned in the feeder before starting the machine. This will ensure that the wire is fed into the dies properly and that the nails are cut correctly.

Keep Your Hands Away From the Moving Parts

It is important to keep your hands and fingers clear of the moving parts on the wire nail-making machine. This will help to prevent any injuries from occurring.

Don’t Overload the Machine

It is important not to overload the wire nail-making machine. This can cause the machine to stop working properly and may damage the parts.

Always Check for Any Obstructions

If the wire nail-making machine starts making strange noises or vibrating abnormally, stop it immediately and check for any obstructions. This may be a sign that something is wrong with the machine and that it needs to be repaired.

Always Wear Safety Gear

It is important to wear safety goggles when using the wire nail-making machine. This will help to protect your eyes from any debris or wire fragments that may be ejected from the machine.

These tips will help you safely operate the wire nail-making machine and avoid potential accidents. For more information on how to use this equipment, consult our Awnail team for assistance.

7. 5 Tips for Maintaining the Wire Nail Making Machine

To ensure your wire nail making machine is always running at its best, here is an easy guide to follow for maintaining the machine!

| No. | Tips |

|---|---|

| 1 | Keep The Machine Clean |

| 2 | Keep The Machine Lubricated |

| 3 | Always Check The Belts And Chains |

| 4 | Keep The Cutting Blades Sharp |

| 5 | Inspect Wirings |

#1 Keep The Machine Clean

Keep the machine clean. The machine needs to be free of any debris or dust to function properly. Make sure to wipe it down regularly.

#2 Keep The Machine Lubricated

Lubricate the moving parts. This will help keep the machine running smoothly.

#3 Always Check The Belts And Chains

Check the belts and chains for wear and tear. If they are showing signs of wear, they will need to be replaced.

#4 Keep The Cutting Blades Sharp

Keep the cutting blades sharpened. Dull blades can cause poor quality nails and lead to decreased productivity.

#5 Inspect Wirings

Inspect the wiring for any signs of damage or wear and tear. If there is any damage, it will need to be repaired or replaced.

Following these tips will help keep your wire nail-making machine running smoothly and producing high-quality nails. For more information on maintaining wire nail-making machines, contact the experts at Awnail. They will be happy to help!

8. Benefits of Using a Wire Nail Making Machine

There are many benefits of using a wire nail-making machine. Some of the key benefits include:

High-Quality Nails

The nails produced by a wire nail-making machine are of high quality, thanks to the precise cutting blades and consistent pressure.

Increased Productivity

A wire nail-making machine can produce nails at a much faster rate than someone could by hand. This can lead to increased productivity and decreased costs.

Consistent Results

A wire nail-making machine produces nails that are consistently the same size and shape, which is not always possible when they are made by hand.

Lower Costs

A wire nail-making machine can produce nails at a lower cost than if they were made by hand.

If you are looking for a high-quality, cost-effective way to produce nails, then a wire nail-making machine is the solution for you. Contact a wire nail manufacturing company like Awnail today to learn more about their products and services.

9. Finding the Best Wire Nail Making Machine for Your Needs

There are a few factors you will want to consider when looking for the best wire nail-making machine for your needs.

Size of the Machine

The most important factor is the size of the machine. You will want to make sure that the machine can accommodate the size of nails you will be manufacturing.

Speed of the Machine

Another important factor is the speed of the machine. You will want to make sure that the machine can produce nails at a rate that meets your needs.

If you are producing a large number of nails, you will want a machine that can keep up with your production demands.

Price of the Machine

Finally, you will also want to consider the wire nail making machine price. Make sure you select a machine that fits within your budget.

When considering all of these factors, you should be able to find the best wire nail-making machine for your needs.

10. Who Can Benefit From Using a Wire Nail Making Machine

A wire nail-making machine can be beneficial for a variety of people. Some of the most common beneficiaries of using a wire nail making machine include:

Contractors

Contractors can benefit from using a wire nail-making machine because it can help them save time and money. Instead of having to order nails from wire nail making machine manufacturers, they can manufacture their nails with a wire nail-making machine.

This can save them time and money since they won’t have to wait for the nails to arrive and they won’t have to pay for the shipping costs.

Carpenters

Carpenters can also benefit from using this best wire nail making machine. When they need to make a quick repair or build something new, they can use the wire nail-making machine to create the nails they need.

This can save them time and the wire nail machine price is cheaper since they won’t have to go to a hardware store to buy nails.

Homeowners

Homeowners can also benefit from using a wire nail-making machine. If they ever need to repair something around their home, they can use the wire nail-making machine to create the nails they need.

This can be a cost-effective solution since they won’t have to purchase nails from a hardware store or the wire nail machine manufacturers.

Construction Workers

Construction workers can also benefit from using a wire nail-making machine. When they’re working on a construction project, they often need to have a lot of nails on hand.

With a wire nail manufacturing machine, they can manufacture their nails, which will save them time and money.

In conclusion, many people can benefit from using a nail wire making machine. These are just a few of the common groups of people who can take advantage of this type of machine. If you’re in one of these groups, wire nail making machine manufacturers can be valuable for you.

11. Conclusion

Wire nails are an excellent choice for a variety of applications including construction, furniture, and many others. They’re also known as “wire staples” or “staples with wires.” In this post, we covered the basics of how these types of machines work and what you need to know before purchasing one.

If you have any questions after reading this article, please feel free to reach out to our Awnail team! We’d love to assist you with this machine and help people find the right machine for their needs. Contact us!

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us