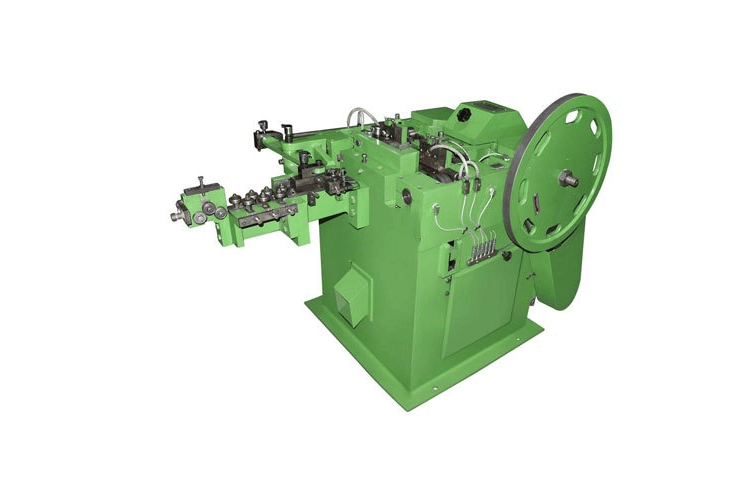

Exceptional Thread Rolling Machine For Your Business

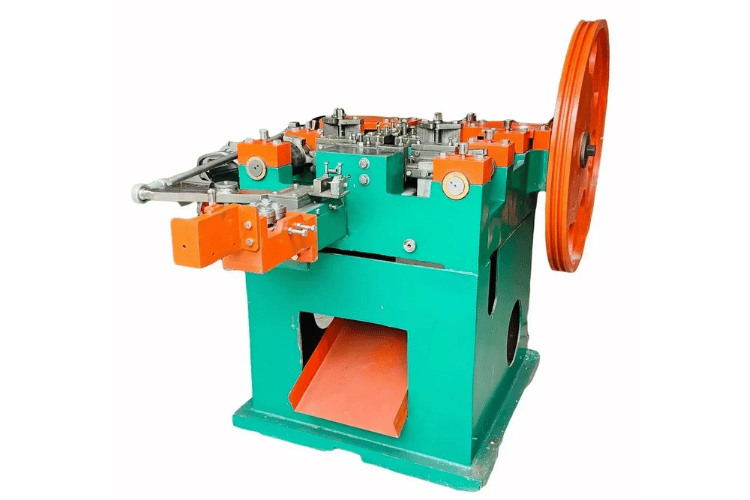

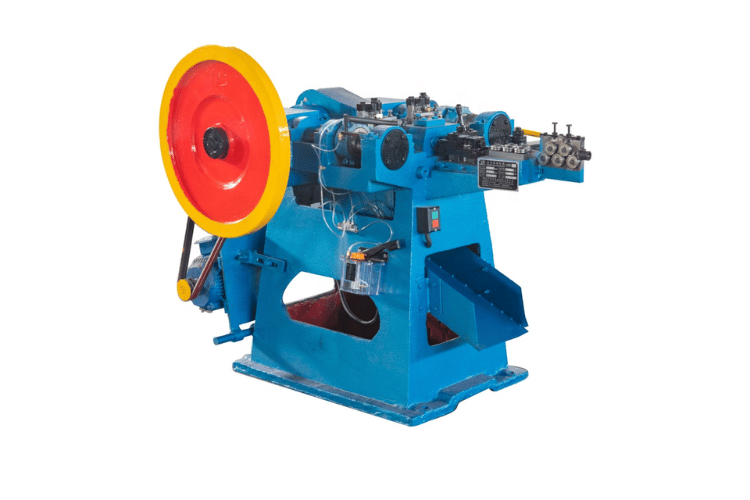

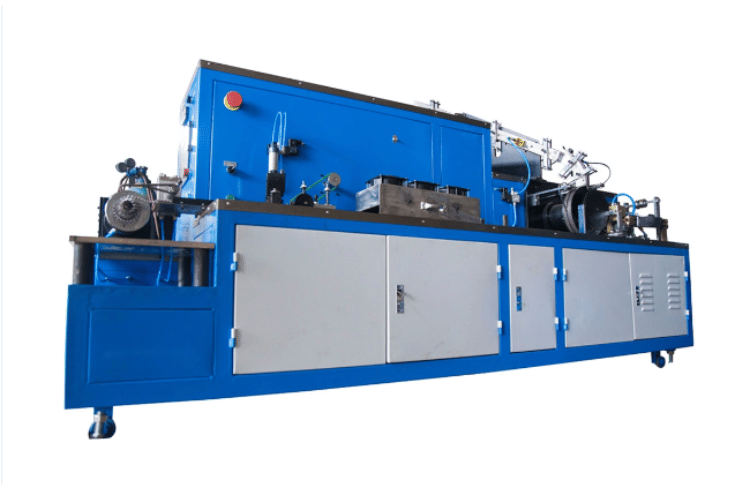

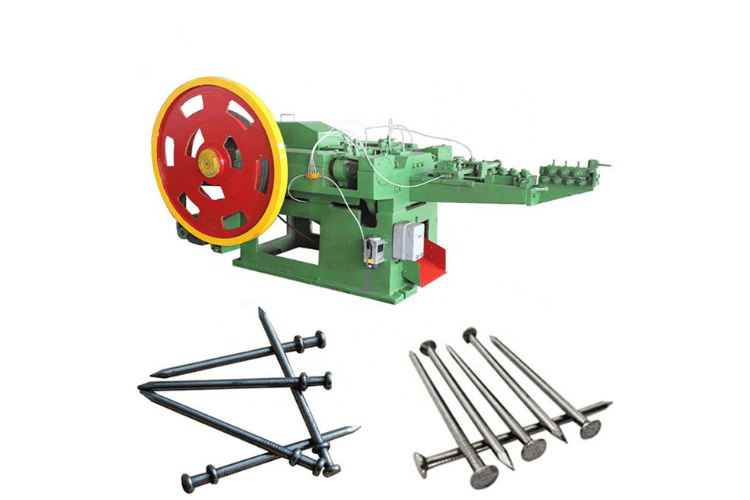

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

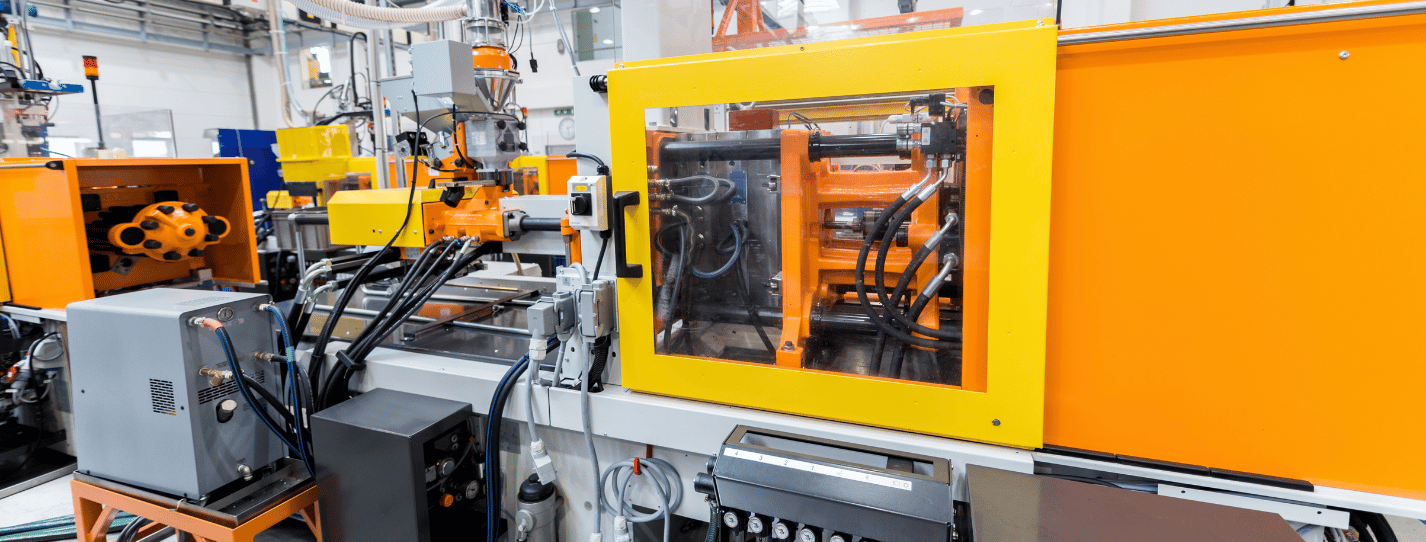

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Features and Benefits of Thread Rolling Machine

Features of Thread Rolling Machines

High-Speed Production Capabilities

Precision Engineering for Consistent Quality

Energy-Efficient Design

Benefits of Using Thread Rolling Machines

Increased Productivity and Efficiency

Enhanced Product Quality and Reliability

Cost Savings and Environmental Benefits

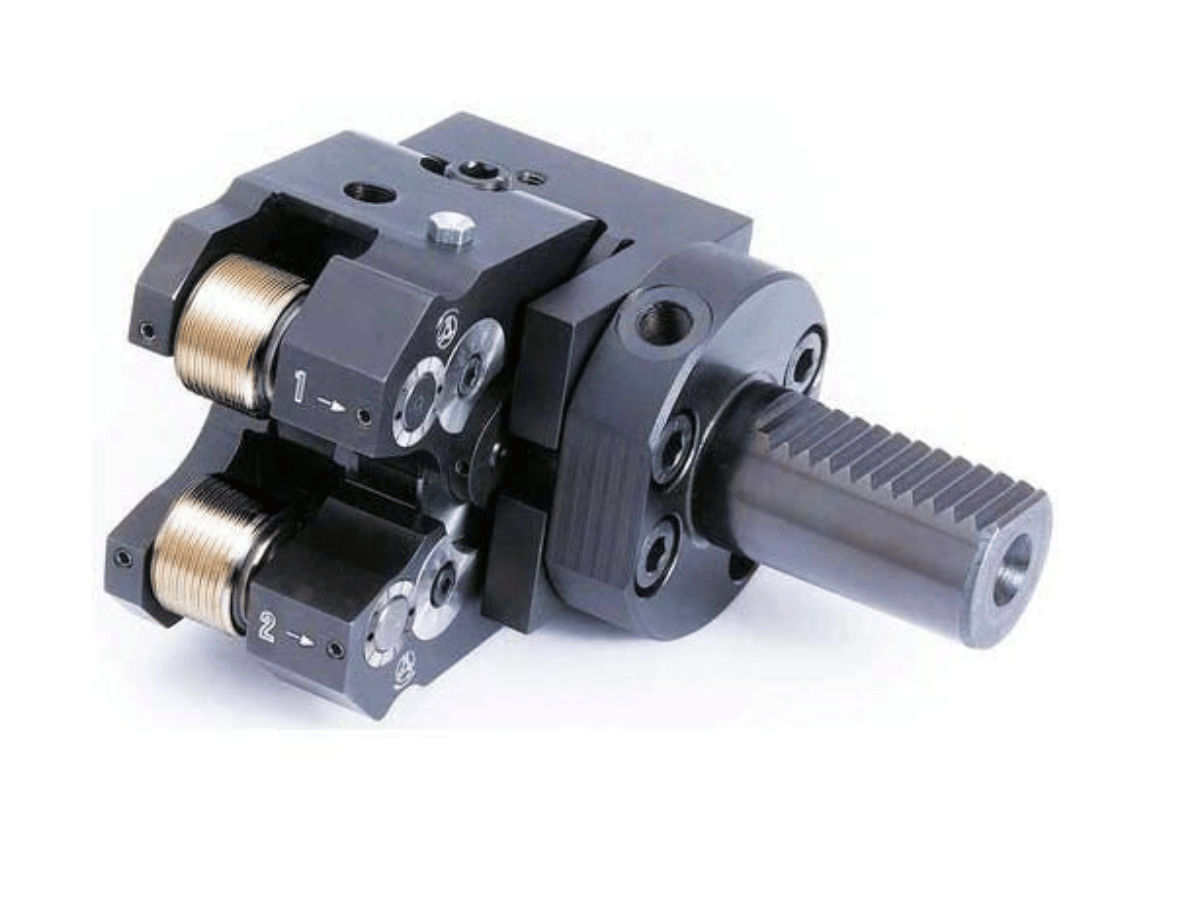

Thread Roller Machine Parts

Thread Roller

Thread Rolling Tools

Reed Thread Roller

Thread Roller Dies

Thread Rolling Machine Flat Die

Thread Rolling Die Head

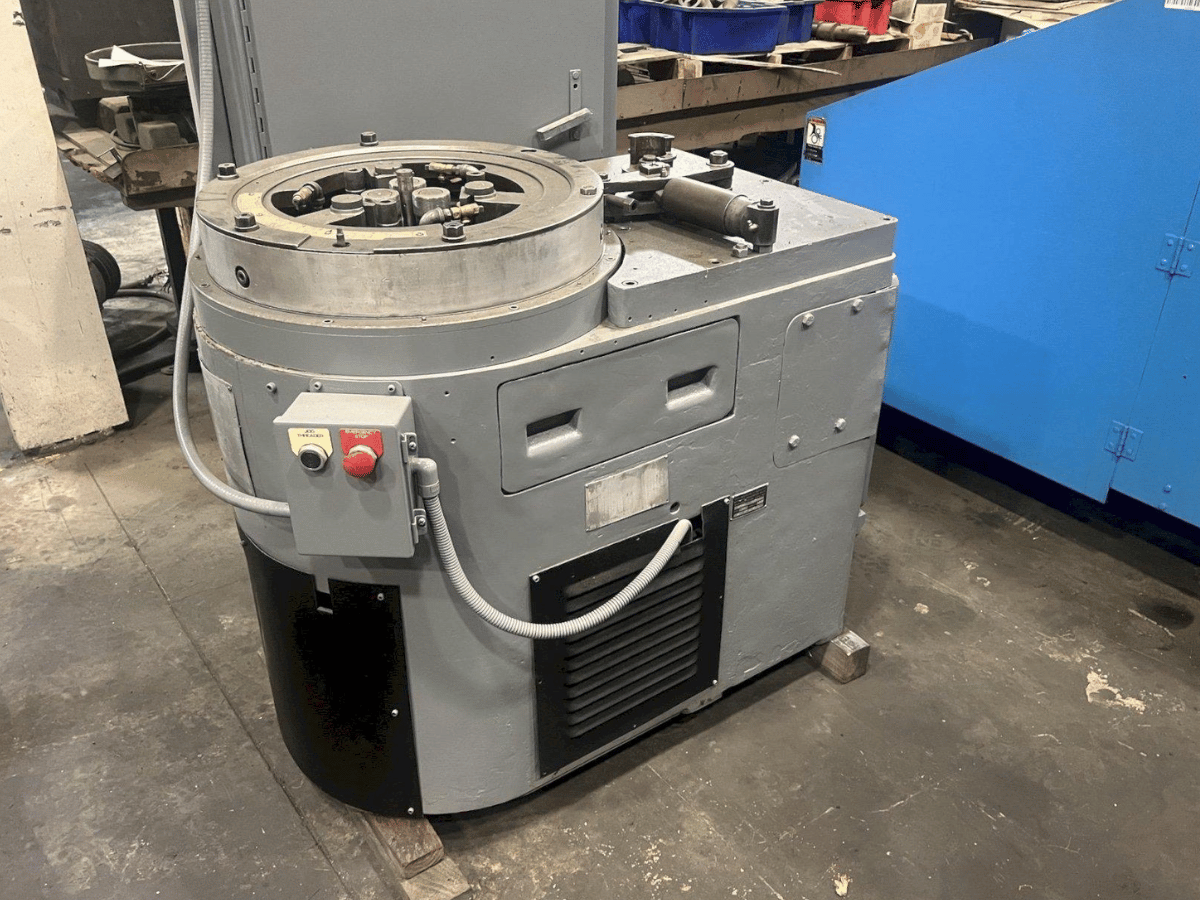

Types of Thread Rolling Machines

Vertical Thread Rolling Machine

Flat Thread Rolling Machine

Screw Thread Rolling Machine

Bolt Thread Rolling Machine

CNC Thread Rolling Machine

High-Speed Thread Rolling Machine

Sizes of Thread Rolling Machines

Mini Thread Rolling Machine

Standard Thread Rolling Machine

Automation Degree of Thread Rolling Machines

Automatic Thread Rolling Machine

Manual Thread Rolling Machine

Raw Materials Used in Thread Rolling Machines

Rebar

Spoke

Thread Rolling Machine Price

Applications of Thread Rolling Machine

Manufacturing Industry

Construction Industry

4 Considerations When Buying a Thread Rolling Machine

#1 Machine Capacity and Size

#2 Precision and Quality of Thread Formation

#3 Speed and Efficiency of Production

#4 Durability and Maintenance Requirements

Dive Deeper Into Our Resources

- Thread Rolling Machine China

- Hydraulic Thread Rolling Machine

- Flat Die Thread Rolling Machine

- Small Thread Rolling Machine

- Wire Nail Making Machine

Technical Insights and Comparisons

- What Is Thread Rolling Process?

- Thread Rolling vs. Thread Cutting: A Comprehensive Comparison

- Exploring the Diverse Industrial Uses of Thread Rolling Machines

Buyer’s Guides and Supplier Information

- An Ultimate Buyer’s Guide to Thread Rolling Machines

- 8 Essential Steps to Find Reliable Thread Rolling Machine Suppliers

Operational Guidance

Market Trends and Analyses

- Thread Rolling Machines: A Deep Dive into Market Trends

- Thread Rolling Machine Market: Emerging Trends & Future Predictions

- Thread Rolling Machines Worldwide: A Global Perspective

Nail Making Machine Focus

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

- Unveiling the Top 8 Thread Rolling Machine Manufacturers

Thread Rolling Machine

The high-speed thread rolling machine is used to produce the round wire from the flat wire. The machine adopts the belt transmission and fixed roller, which can ensure the stable running of the machine, and it has high efficiency.

The thread rolling machine setup is a cost-efficient and energy-saving machine that will quickly and easily roll your metal nails.

This machine is perfect for both personal and professional use and is sure to provide you with a high-quality experience.

1. Thread Rolling Machine Definition and How It Works

A thread rolling machine is a specialized tool used to create a thread on metal objects. It works by using a series of rotating dies to press and form the thread onto the object. This process can be used to create a thread on both nails and screws, making them easier to grip and turn.

Here’s how it works:

Heat the Material

The thread rolling process begins by heating the material to a high temperature, which makes it softer and easier to cut a thread into.

Lubricate the Thread Die

The thread die must be lubricated before threading begins, otherwise, the material will become knotted off in the thread die. The thread rolling die head should be round in shape, with threading teeth cut into the top of it.

Feed the Heated Material

The thread rolling machine flat die has a thread rack that holds thread dies in place until threading begins.

Threading begins by feeding the heated material into the thread die and pulling it back out of the thread rack to ensure that the teeth on the thread die have made thread grooves in the material.

Once thread grooves have been cut into all thread dies, threading is repeated until the thread dies are removed from the thread rack and replaced with clean thread dies.

Cut the Wire Nail into Desired Shape

The wire nail is pulled back out of the thread rack at high speeds, which causes the thread to be cut into the wire nail. All thread dies must be replaced after threading has been completed.

In round die thread rolling machines, wire nails must first be fed into the rolling thread machine before threading begins; this ensures that thread grooves and thread shoulders are formed in thread nails.

For additional questions with regards to thread rolling machines, feel free to contact us at Awnail, our agents are always available to assist with your machinery needs.

2. Thread Rolling Machine Key Features

The thread rolling machine is a device that is used to create a thread on wire nails. The round die is used to create the thread on the wire nail. This thread is used in various applications.

Versatility

Some of these applications include threading screws, bolts, and nuts into metal or plastic materials.

Flexibility

The roller threading machine includes the ability to create a thread on wire nails of virtually any size.

Different Thread Profiles

A flat thread rolling machine is universal. This allows for different thread profiles depending on the application needed by the consumer.

3. Types of Thread Rolling Machine

There are 3 types of thread rolling machines: round die thread rolling machines, flat die thread rolling machines, and thread rolling machines with a rotary die.

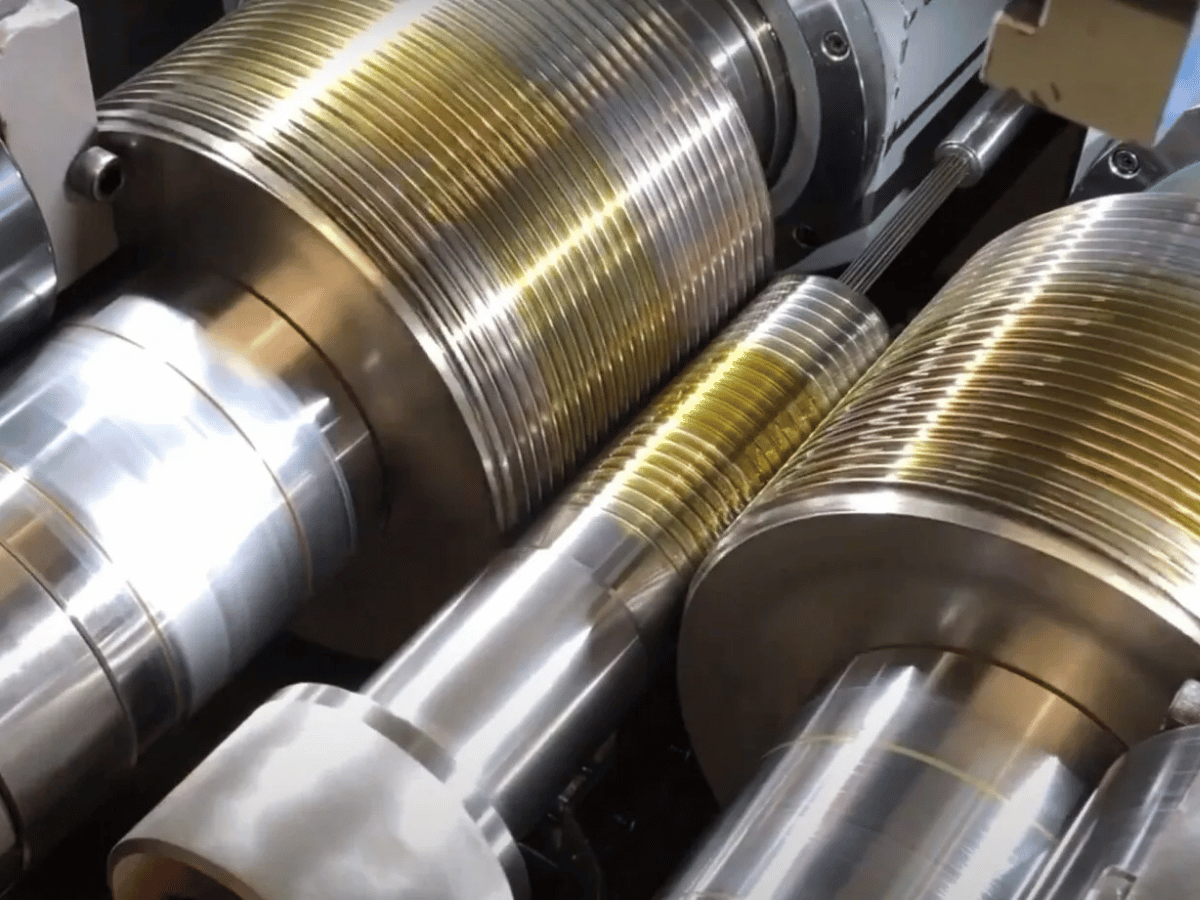

Round Die Thread Rolling Machine

Round die thread rolling machines are used for threading round materials, including grooved rounds. These thread rolling machines can also thread shoulders to help improve the load-bearing capability of the material.

Flat Die Thread Rolling Machine

Flat die thread rolling machines are used to thread flat materials, but they can’t thread grooves or shoulders effectively. One common use is the threading of thread-rolled rods.

Two-Die Cylindrical Thread Rolling Machine

The two-die cylindrical thread rolling machine is a specialized machine that is used to thread metal objects. It consists of two rotating dies that press and form the thread onto the object. This process can be used to thread both nails and screws, making them easier to grip and turn.

4. Parts & Construction of Thread Rolling Machine

There are several parts and construction of the thread rolling machine. Some key components include the round die and the thread rolling machine itself.

Round Die

The round die is what shapes the thread, while the wire nails serve as the thread’s end product. The round die is a disk shape that forms the thread itself.

The shape and size of the round die vary depending on what thread type is required and the threading machine that it will be used.

Thread Roller

The thread rolling machine twists and tightens the wire nails to create a sturdy thread.

The thread winding axis attaches the round die to the thread rolling machine’s motor shaft. The guide rail is a flat metal bar that allows the nail thread rolling machine to move in a straight line.

The thread cutting device cuts the thread produced by the small thread rolling machine into the desired length.

The thread winding axis, guide rail, and thread cutting device are all enclosed within an outer casing of the thread rolling machine. This casing is usually plastic or steel and helps protect internal thread rolling machine parts.

5. Thread Rolling Machine Manufacturing Process

The contact operation of a metal nail production thread rolling machine is a simple process. Here’s the rundown:

Step#1 Select the Correct Die

The thread rolling machine manufacturing process begins with the selection of the correct round die.

Step#2 Mount the Thread Rolling Machine

The round die is then mounted onto the automatic thread rolling machine and the wire nails are fed into the die.

Step#3 Activate the Machine and Cut to Length

The machine is then activated and the nails are rolled into thread. The thread is then cut to the appropriate length.

The fully automatic thread rolling machine manufacturing process is completed.

Here’s a video of thread rolling machine in action!

6. Benefits of Using Thread Rolling Machine

A thread rolling machine is a powerful tool that can be used for a variety of purposes. Some of the benefits of using a thread rolling machine include:

Consistency

There are several reasons why you might want to use a flat die thread rolling machine. Thread roll machines can help you produce more consistent threading. A thread rolling machine operator with the correct training can also lead to further consistency.

Uniform Threading

A thread rolling machinery also helps you create neater and more uniform threading, which can be important for a variety of applications.

Cost-Effective

Additionally, thread rolling equipment with the correct thread rolling machine specification can help you save time and money.

They’re an efficient way to produce round wire nails, and they can also help you avoid common mistakes that can occur during the threading process.

7. Where to Find Wholesale Thread Rolling Machine For Sale

If you’re in the market for a thread rolling machine, there are a few places you can look to find a good deal.

Awnail

First, try contacting thread rolling machine manufacturers, like Awnail directly. Often, they’ll have machines for sale at a discount because they’re overstocked or are retiring an older model.

Auction Sites

Another option is to search online auction sites like eBay or Alibaba. You can often find used or refurbished machines at a fraction of the cost of a new one.

In the types of thread rolling machine such as vertical thread rolling machine, CNC thread rolling and wire thread rolling machine, it is usually wise, to ask questions to the manufacturer first.

Just be sure to read the listing carefully and ask the seller questions about the condition of the thread roller machine before bidding.

Trade Shows

Finally, if you’re not in a hurry to buy, keep an eye out for nail rolling machine sales or a roll threading machine for sale.

CNC thread rolling machine, Ort thread rolling machine, Mini thread rolling machine, at trade shows or industrial auctions.

Sometimes you can find thread rolling machines,a thread rolling machine for nails, and other industrial equipment at a great discount if the manufacturer is making room for new machinery.

8. Qualities of a Reliable Thread Rolling Machine Manufacturer

When looking for a thread rolling machine manufacturer, it is important to consider the qualities of the company. Some of the key qualities of a reliable thread rolling machine manufacturer are:

Improves Their Operations

When thread rolling machines were first manufactured, they were built by hand. Over the years, thread rolling machine manufacturers have improved and automated their procedures to produce thread rolling machines faster and more efficiently.

Invests in People and Technology

Companies that have been around for a long time and who have invested in both people and technology are likely to be reliable thread rolling machine manufacturers.

High Standards

These companies spend a lot of time and effort ensuring that their thread rolling machines are produced to the highest standards, resulting in thread rolling machines that are durable, efficient, and versatile.

9. Average Cost of Thread Rolling Machine

The average cost of a thread rolling machine can vary depending on the features and size of the machine. Typically, thread rolling machines range in price from around US$1,500 to US$10,000.

10. 10 Tips for Thread Rolling Machine Maintenance

Thread or screw rolling model machinery requires forming a designed maintenance routine for it to be able to perform well and last long. Here are some tips to keep your workpiece in the best condition:

| No. | Tips |

|---|---|

| 1 | Inspect Before Use |

| 2 | Keep it Lubricated |

| 3 | Clean the Machine |

| 4 | Replace Dies Often |

| 5 | Use Soft Cloth for Cleaning |

| 6 | Store Properly |

| 7 | Ask for Professional Assistance |

| 8 | Keep Spare Parts on Hand |

| 9 | Replace Thread as Needed |

| 10 | Schedule Regular Maintenance |

#1 Inspect Before Use

Inspect the thread rolling machine before use each day. Look for any damage or signs of wear.

#2 Keep it Lubricated

Lubricate the thread rolling machine as needed using light oil.

#3 Clean the Machine

Keep the thread rolling machine clean by wiping it down with a clean cloth after each use.

#4 Replace Dies Often

Replace the round die as needed. Thread rolling machine spare parts should also be prepared just in case a part gives way.

#5 Use Soft Cloth for Cleaning

Clean the thread rolling machine at the end of each workday using a cloth and a light cleaner.

#6 Store Properly

Keep the wire nails separate from other tools and materials to prevent damage and wear on the thread rolling machine.

#7 Ask for Professional Assistance

Your thread rolling machine should only be repaired by a professional. Contact your local appliance repair team for assistance.

#8 Keep Spare Parts on Hand

Keep the thread on hand to replace thread that has become worn or damaged.

#9 Replace Thread as Needed

Replace thread as needed, following the thread replacement instructions found in the owner’s manual for your thread rolling machine model. A thread rolling machine pdf or thread rolling machine video is usually included in the owner’s manual

#10 Schedule Regular Maintenance

Perform routine maintenance on your thread rolling machine every month by lubricating the machine with light oil and cleaning it.

11. Conclusion

Our high-speed thread rolling machine is perfect for both personal and professional use. It’s a cost-efficient and energy-saving machine that will quickly and easily roll your metal nails.

With this machine, you can quickly and easily produce the round wire from the flat wire. The machine adopts the belt transmission and fixed roller, which can ensure the stable running of the machine, and it has high efficiency.

You won’t find a better or more efficient way to roll your metal nails than with our high speed thread rolling machine. Purchase a thread rolling machine today from Awnail!

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us