The leading Nail Making Machine Manufacturer Since 1999

Welcome to the world of precision and efficiency with our state-of-the-art nail making machines. Explore our range of machines designed to meet your unique needs, ensuring seamless nail manufacturing with unmatched quality.

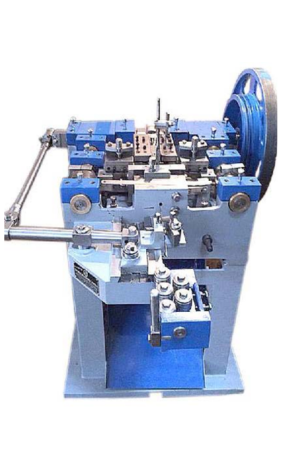

Nail Manufacturing Machine Gallery

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent

High Production Efficiency

Our nail machines are super fast, making more than 1050 nails a minute. This speed is five times faster than regular nail machines. This means you can make a lot more nails faster, helping you grow your nail making business by making your production line quicker and more efficient.

Energy Consumption

Our nail machines are designed to use less energy. They have smart tech that cuts down on how much electricity they use. On average, making a ton of nails uses about 27 kilowatt-hours (kWh) of electricity. By using our machines, you save on electricity costs, making your nail making cheaper and better for the environment.

Our Success in Numbers

With over 20 years of industry leadership, we excel in state-of-the-art nail making machines that deliver precision and reliability. Our commitment to innovation and quality ensures your business can consistently produce high-quality nails, meeting the highest industry standards.

Play Video

0

+

Years of Expertise

0

+

Countries Served

0

+

Square Feet of Manufacturing Space

0

+

Custom Projects Completed

Certified Excellence: Ensuring Quality and Safety

Dive into the world where quality meets safety with our certified nail manufacturing machines. It’s our commitment to providing you with reliable, efficient, and safe equipment for your nail manufacturing needs.

Why Choose Awnail

Expertise in Machine Operation

Our team provides comprehensive training and support to simplify nail making machine operation. We ensure your staff is well-prepared to handle our machines efficiently, reducing additional training costs and streamlining production.

Quality Assurance

We take quality seriously. Our advanced machines, with top-notch technology and strict checks, always make top-quality nails that meet the best industry levels, so you don’t have to worry about nail quality.

Efficiency Boost

Our nail making machines are designed for speed, producing over 1050 nails per minute, which is five times faster than standard machines. This efficiency boost allows you to significantly increase your production capacity, making your operations more productive.

Customization for Product Diversity

Our nail making machines offer versatility and flexibility, accommodating a wide range of nail types and sizes, including custom designs. You can expand your product offerings and meet unique customer demands effectively with our tailored solutions.

Eco-Friendly Solutions

We’re committed to reducing the environmental footprint of nail production. Our machines are designed for maximum energy efficiency and minimal waste, utilizing cutting-edge technology to ensure sustainable manufacturing practices.

Market Responsiveness

We quickly adjust our products to match changing market needs by closely monitoring industry trends and listening to customer feedback. This agility allows us to provide innovative solutions that enhance productivity and ensure our clients remain at the forefront of the nail manufacturing industry.

Our Success Stories

Sarah Smith, an experienced business owner in the construction field, had a big problem with getting nails of different sizes and lengths from various suppliers. This made her worry about the quality of her construction projects. To solve this, she started using our special nail making machine, which was made to fix this exact problem. Thanks to this machine, Sarah's company now makes nails that are all the same size and length, matching her high standards. This has helped make her construction projects stronger and more reliable. Our machine helped Sarah keep her good name in construction. It did this by dealing directly with the issue of nail size and length differences.

Carlos Rodriguez runs Rodriguez Roofing Supplies. He had trouble offering different kinds of nails for various construction projects. His suppliers couldn't provide many options. To solve this problem and search for more nail making machine choices, he started using our flexible roof nail making machine that can make many types and sizes of nails. This change allowed Carlos to meet the needs of more construction and woodworking projects. It greatly improved his ability to attract and help customers with different demands.

Mark Anderson is an experienced mechanical engineer with a passion for the nail manufacturing industry who founded Precision Nails, LLC. The company faced challenges due to its reliance on outdated, hand-operated machines that slowed down production. Fortuitously, a partnership with Awnail brought about a significant change, as Awnail provided modern, automated machines equipped with advanced technology. This upgrade resulted in considerable labor cost savings and increased nail production speed. Consequently, Precision Nails, LLC, can now maintain competitive pricing while still securing a profit.

Previous

Next

Your Guide to Frequently Asked Questions

Nails are typically produced through a series of processes, including wire drawing, cutting, shaping, heading, and finishing. These processes transform raw materials into finished nails.

Quality control in nail production involves monitoring dimensions, weight, surface finish, and tensile strength to ensure that the nails meet industry standards and specifications.

Yes, our machines can be configured to produce nails with various coatings to enhance durability and resistance to corrosion.

The lifespan of a nail making machine depends on factors like usage, maintenance, and the quality of materials used. Generally, our nail making machine can be expected to have a lifespan of 10 to 20 years or more.

Our machines are versatile and can produce a wide range of nail types, including common nails, finishing nails, roofing nails, and more.

The production capacity varies depending on the specific model. We offer machines with different production rates to meet your business needs.

Absolutely. Our machines are adjustable to accommodate various nail sizes and lengths, providing flexibility in production.

Our machines come with advanced safety features to protect operators during operation. These features include emergency stop buttons and safety guards.

Yes, we offer comprehensive technical support and after-sales service to ensure the smooth operation of our nail making machines. Our team is available to assist you with any issues or questions you may have.

You can request a quotation or seek more information by contacting our sales team through the provided contact details on our website. We’ll be happy to assist you with your inquiries.

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us

Awnail is committed to address any inquiries you may have and ensure your satisfaction with our products and services.