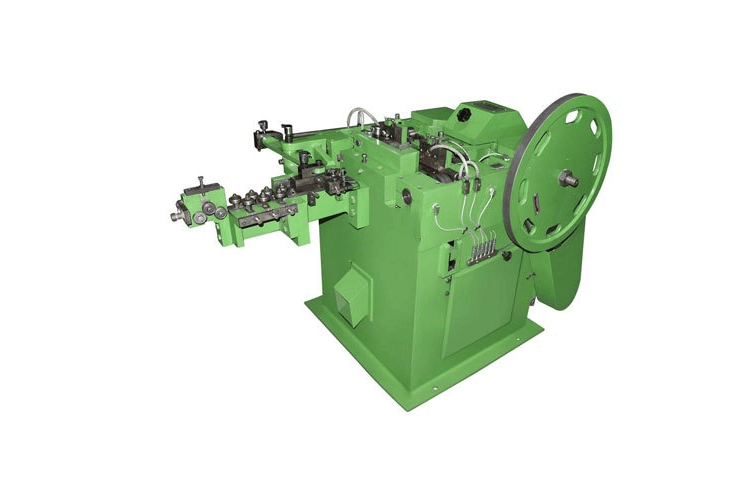

Exceptional Coil Nail Making Machine For Your Business

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

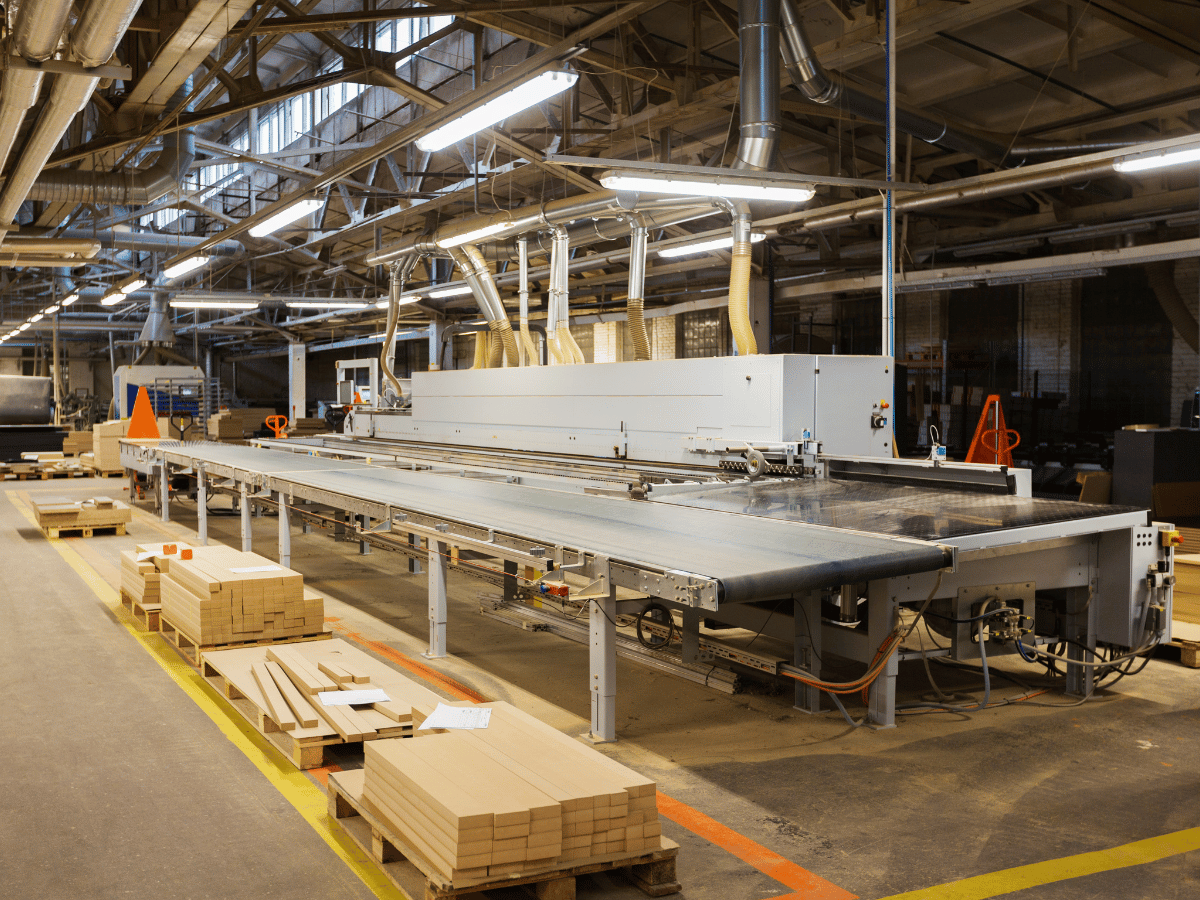

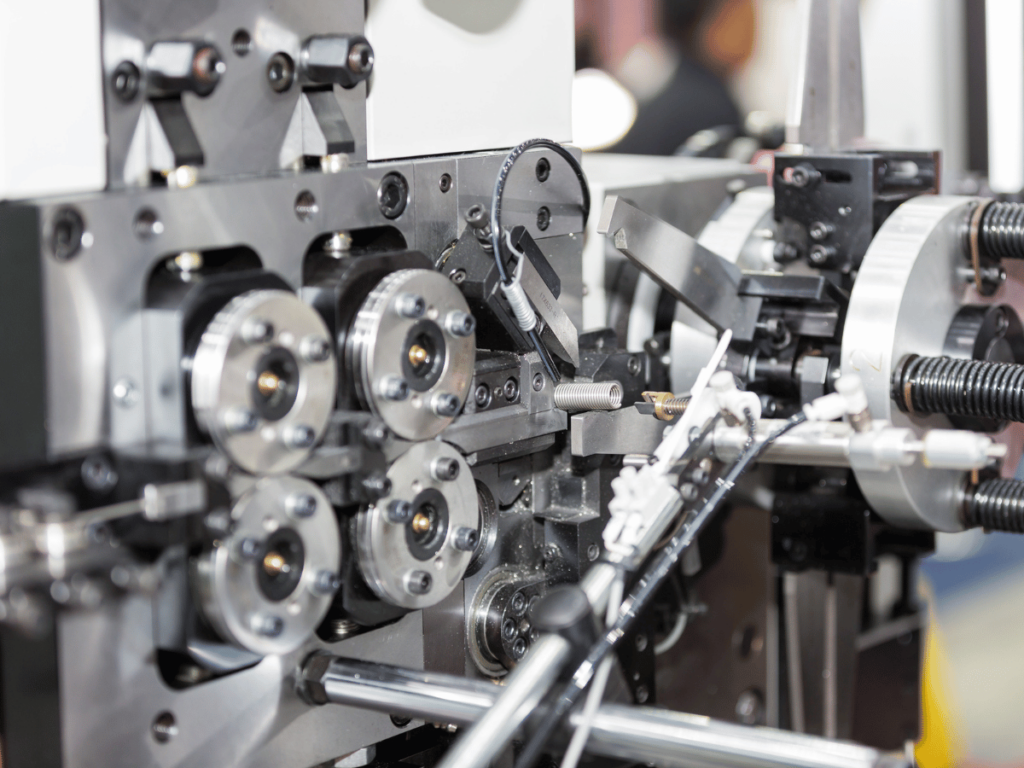

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Features and Benefits of Coil Nail Making Machine

Features of Coil Nail Making Machine

High-Speed Capabilities

Advanced Automation Technology

Durable and Reliable Build

Benefits of Coil Nail Making Machine

Consistent Quality Output

Easy Operation

Safety Features

Application of Coil Nail Making Machine

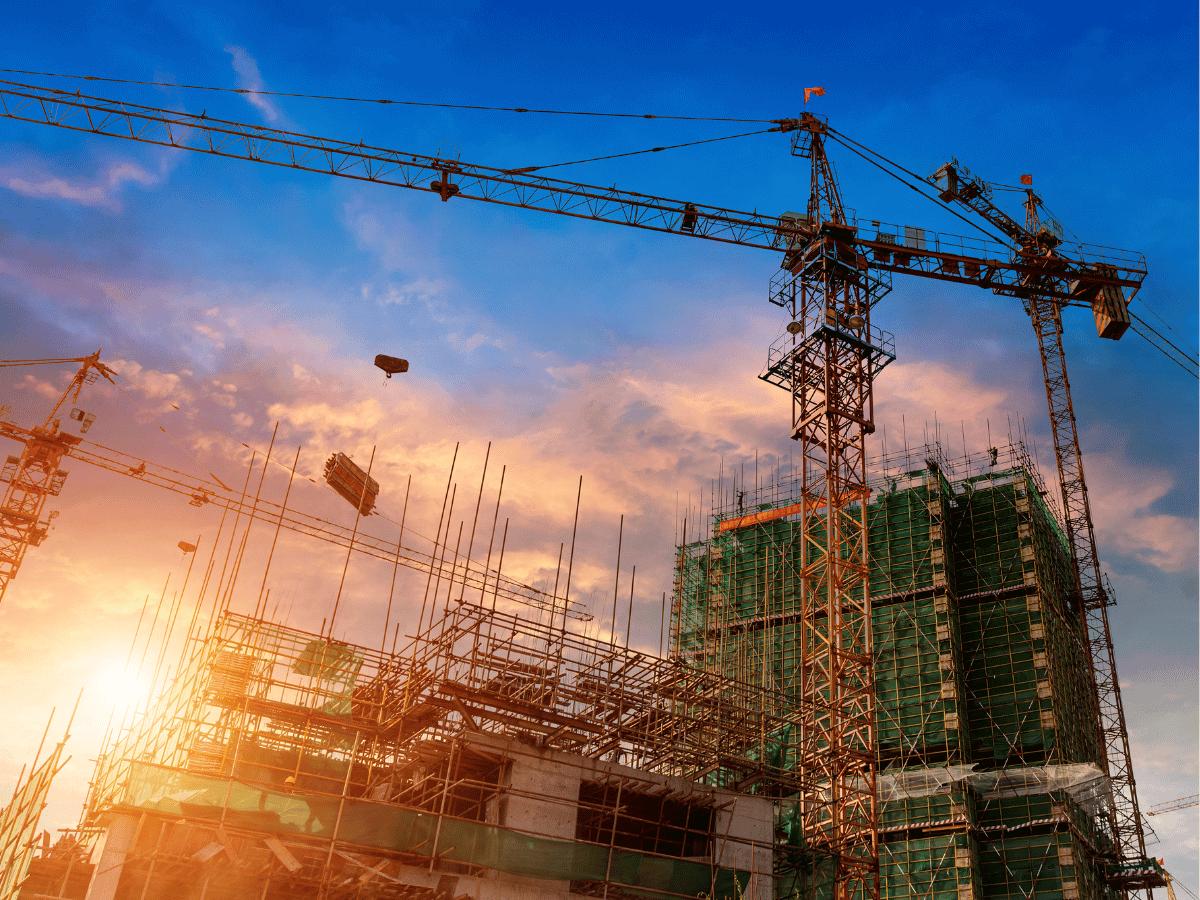

Construction Industry

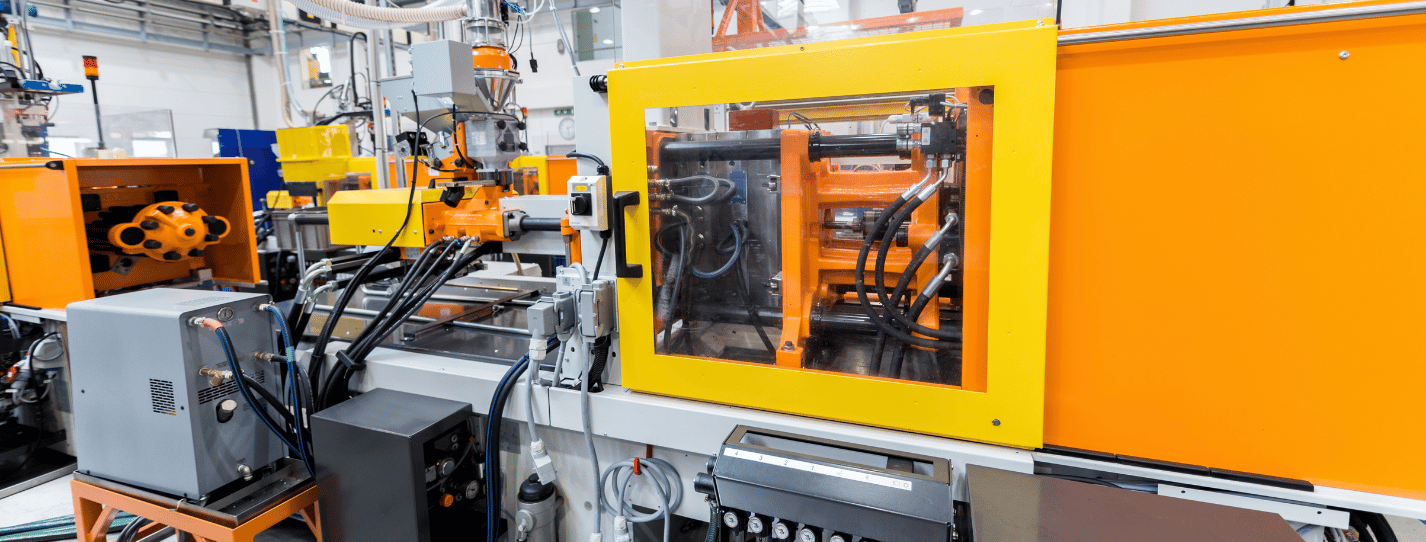

Packaging and Pallet Making

Furniture Manufacturing

4 Considerations When Buying Coil Nail Making Machine

#1 Maintenance Requirements

#2 Technological Features

#3 Cost and Return on Investment

#4 Customizable Settings

Dive Deeper Into Our Resources

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

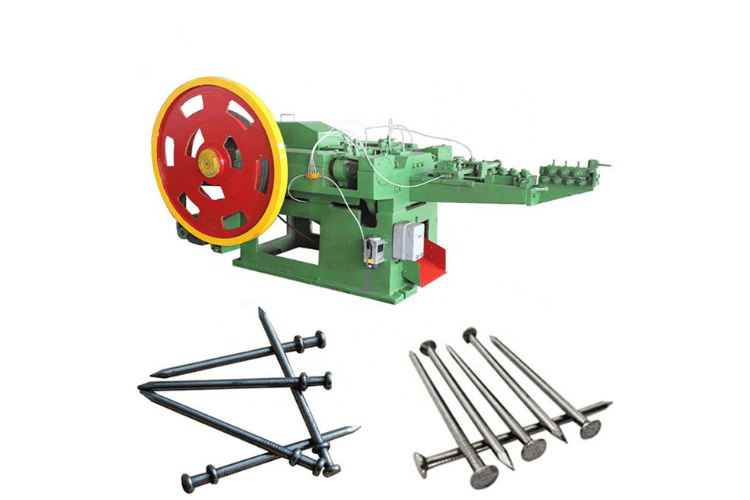

Coil Nail Machine

The coil nail machine is perfect for quickly and easily installing nails into wood. It has a durable design and comes with a variety of features to make your job easier, including a quick-load magazine, automatic firing, and adjustable depth control.

Coil nails have a flat head and are often used in construction, manufacturing wood pallets, building materials, and other commercial applications. It can be nailed directly by different output devices such as coil nail guns or coil staplers.

A coil nail machine is the best choice for you because coil nails are easier and faster to install than coil staples.

1. Coil Nail Machine Definition and What Does It Do

A coil nail machine is a device specially developed for automatically rolling up the finished nails into the coil nails, which are then automatically sent to the coil stapler for further driving. It is also called a coil nail collator.

The coil nails are widely used in the production process of wood pallets because of their convenience in use. Coil nails are used with coil nail guns and coil staplers, but coil nail machines can be applied to both coil guns and coil staplers.

The coil nail machine mainly consists of coil nails, coil, anvil, and other components. The main body is composed of the main body, while the coil nails are installed on the cartridge for installation. If you need to adjust the depth of coil nails, you can use the coil nail machine’s adjustment knob.

2. Coil Nail Machine Composition

The coil nail machine is composed of a coil, a mandrel, and an anvil.

Coil

The coil is usually made of steel material and has coil nail machine’s coil specifications. For example, if the coil specification can hold 5-inch coil nails, then it can hold any coil nail that falls into that size range.

Mandrel

A mandrel is a tool used to hold coil nails during the injection cycle before coil nails are cut off on the coil nail machine’s anvil.

Anvil

The coil nail machine’s anvil is used to cut coil nails during coil nail machine operation.

3. Benefits of Coil Nail Machine

Several benefits come with using a coil nail machine. Some of the top benefits include:

| No. | Benefits |

|---|---|

| 1 | Increased Productivity |

| 2 | Increased Accuracy |

| 3 | Reduced Fatigue |

| 4 | Ease Of Use |

| 5 | Hassle-Free |

| 6 | Safety |

| 7 | Noise Reduction |

| 8 | Durable |

| 9 | Versatile |

| 10 | Reduction Of Maintenance Costs |

Increased Productivity

A fully automatic nail-making machine can help you to increase your productivity by nailing up to 10 pcs min nails per minute at a speed. This means that you can get your work done much faster, which can be extremely helpful if you are on a deadline.

Increased Accuracy

When you are using a coil nail making machine, you can achieve a higher level of accuracy than when you are using a traditional hammer and nails. This is because the coil nail machine drives the nails straight, which reduces the likelihood of them splitting or bending.

Reduced Fatigue

A fully automatic nail making machine requires less force to use than a hammer and nail, which means that they can reduce your fatigue while you are working. This is especially helpful for people who have to do a lot of work with nails regularly.

Ease Of Use

An automatic coil nail machine is much easier to use than a traditional hammer and nail. Wire nail making machine simply requires you to place the coil nail in the machine and pull it down on a handle.

Hassle-Free

The coil nail machines are hassle-free tools that can save you time, money, and stress. It eliminates the need for having to buy, store and maintain a coil nail gun, coil nails, air compressor, and hose.

Safety

The coil nail machine equipment is much safer than using hammers because you are not required to swing it or come into contact with sharp edges that are created when the coil nails are being driven in.

Noise Reduction

The coil nail machines are much quieter than coil nail guns, which means that coil nail machines are ideal for use in areas where coil nails are prohibited. The coil nail machines also protect your ears from ear damage that can be caused by coil nail guns being fired repeatedly.

Durable

The coil nail machines are more durable than coil nail guns because there is no air compressor or hose attached to them. The coil nail machines do not have any plastic parts that can break easily, which means that coil nail machines are more likely to last you for a very long time.

Versatile

The coil nail machines are versatile tools because they are perfect for different types of projects, including woodworking, construction work, and DIY projects.

Reduction Of Maintenance Costs

The coil nail machines reduce the likelihood of having to pay for maintenance costs, which you would have to spend if you were using coil nail guns or coil nails. coil nails are not as durable as coil nails either, which means that coil nails are much more likely to break or bend.

4. Different Types of Coil Nail Machine

There are several different types of coil nail making machines on the market.

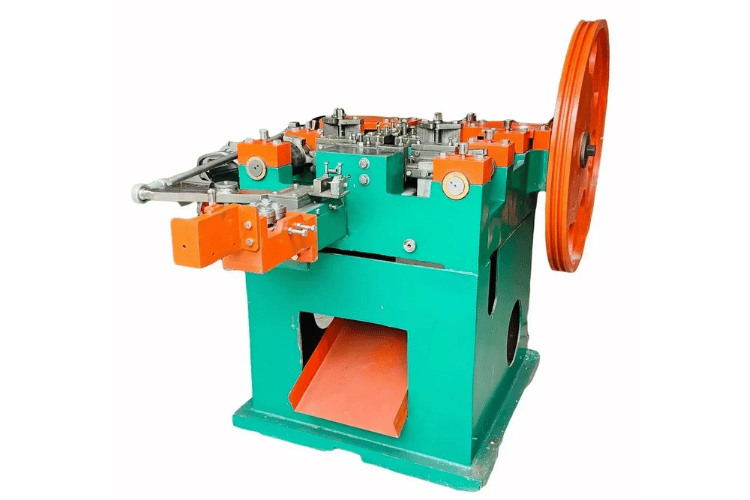

Manual Coil Nail Machine

The most basic type of coil nail machine is the manual coil nail machine. This machine requires you to use a hammer to manually drive the nails into the material that you are working on. While this machine is less expensive than other types of coil nail machines, it can be quite cumbersome and time-consuming to use.

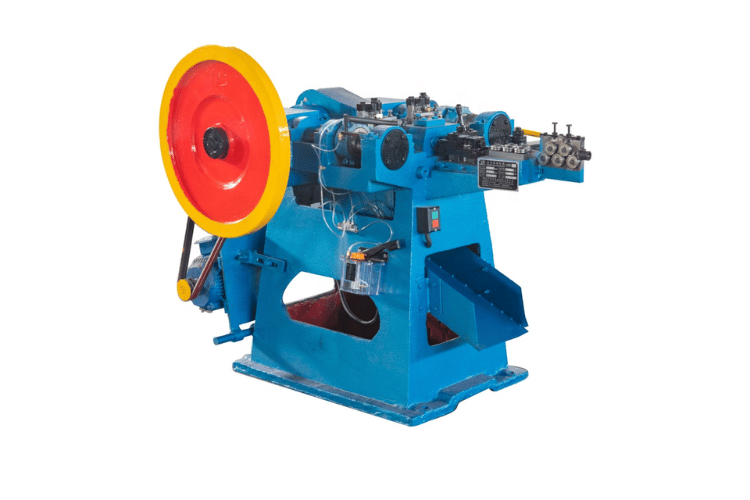

Pneumatic Coil Nail Machine

The next type of coil nail machine is the pneumatic coil nail machine. This machine uses an air compressor to power the nails into the material, which makes it much easier to use than the manual coil nail machine.

However, pneumatic coil nail machines can be quite dangerous, especially if they are not being used for coil nails or coil nails. This is because coil nail guns have a risk of misfiring when they are in use, which can result in serious injuries.

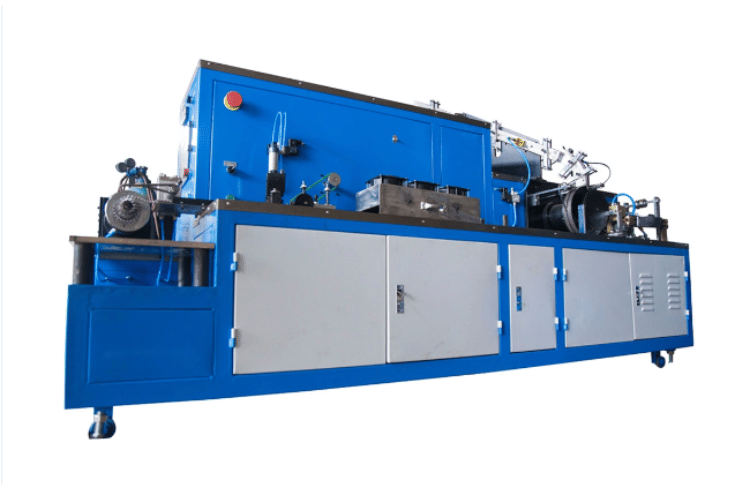

Electric Coil Nail Machine

The final type is the electric coil nail machine. These machines use electricity to power them, but do not require an air compressor to function. An example of this is a pallet coil nail making machine that is paired to a pallet nailer machine.

Electric coil nail machines are easy to use and are great for smaller projects that require coil nails to be used.

If you want to know more about these coil nail making machines, you can contact us at Awnail. We will provide the information that you need. We want all our customers to be informed of coil nail machines so they can use them properly and efficiently.

5. Step by Step Guide on Using Coil Nail Machine

When using a coil nail machine, it is important to know the steps on how to use a coil nail machine. Below is the step-by-step guide on how to use coil nail machines properly.

Step #1 Set Up the Workpiece

The first step in using a coil nail machine is to set up the workpiece. This includes choosing the correct coil wire diameter, nail length, type, and setting up the workpiece in the correct position.

The coil size should be matched to the thickness of the material being nailed, and the coil type should be matched to the shape of the material being nailed.

Step #2 Turn On the Coil Nail Machine

Once the workpiece is set up, the coil nail machine should be turned on. A coil nail machine creates a coil of nails ready to use, so it is important to have them loaded correctly. The coil nails are held together with wire that can be pulled apart when they are needed.

Step #3 Pull Apart the Coil Nails

The coil nails are held together with wire that can be pulled apart when they are needed. The coil nail machine typically has a small handle, loop, or bar that pulls away the wire to separate the coil nails.

Step #4 Place Coil Nails Into Position

It is important to place coil nails into their correct position so they will be driven deep enough into the workpiece to secure it. The coil nails should be placed so they are at least as long as the coil nail is wide, and should not stick out past the top of the workpiece.

Step #5 Drive Coil Nails Into Position

After coil nails have been placed where they need to go, they need to be driven into their position. Coil nails are driven using either coil nail drivers, coil nail standers, or coil nail staplers depending on what is needed for the workpiece.

Step #6 Attach Coil Nails

After coil nails have been driven into position, they need to be attached. Coil nails can be attached by metal coil nails, coil wire coil nails, coil rubber coil nails, or coil plastic coil nails. For this step, the coil nail type must match the coil nail type attached to the workpiece.

Step #7 Remove Excess Materials

If excess materials are still sticking out of the workpiece after attaching coil nails, they should be removed.

By following these steps, coil nails can be attached to the right position on a workpiece. This will ensure that coil nails are deep enough into the workpiece and secure it properly.

Here’s a video of coil nail machine in action!

6. Coil Nail Machine Average Price

The coil nail machine is available in manual, electric, and pneumatic models, and the price range for the machines varies depending on the features of the model.

The average price for coil nail machines is around $2,400. This price is based on coil nail machines with medium to high-end features and a coil wire diameter of 1/4 inches or less.

If you are looking for the exact cost of coil nail machines, you can contact us at Awnail and we can help you find coil nail machines that suit your budget.

7. Factors That Affect Coil Nail Machine Cost

Several factors can affect the coil nail machine cost. The most important ones are the following:

Machine Power

The coil nail machines come in different power capacities, and the more powerful machines usually cost more.

Size and Weight

Larger coil nail machines are typically more expensive than smaller ones. Additionally, coil nail machines that are heavier than average will also be more expensive.

Manufacturer

Some manufacturers charge more for their coil nail machines than others. It is important to compare prices before making a purchase.

Material

Coil nail machines made of different materials will cost differently. For example, coil nail machines that are constructed of steel and other metal components will be more expensive than those made from plastic or wood.

By considering these factors, you can get a coil nail machine that is within your budget.

8. Where to Find the Best Deals on Coil Nail Machine

There are many places where you can find the best deals on coil nail machines. It is important to do your research before purchasing so that you can get the best machine for your needs.

Online Retailers

Some of the best places to find coil nail machines are online retailers such as Amazon and eBay. You can also find good deals on coil nail machines at hardware stores and home improvement stores. Be sure to compare prices before purchasing so that you can get the best deal possible.

Manufacturer’s Website

Another good place to find a coil nail manufacturing machine is the manufacturer’s website. Many manufacturers offer their products at discounted prices on their websites, which can save you a lot of money.

Awnail has been manufacturing the highest quality nail making machines for several years. We have developed a wide range of products to suit all customer needs, from small workshops to large industrial production lines.

Based on long-term partnerships with our customers and suppliers, we are able to offer our clients tailor-made solutions in order to suit their specific requirements. Our expertise in this field enables us to design and manufacture high-precision machinery that is reliable, efficient, and environmentally friendly.

Retail Showrooms

To find coil nail machines, you should consider visiting a showroom or home improvement center to see what’s available in person before making a purchase. Retail showrooms offer coil nail machines at discounted prices, which can help you save money.

Co-Ops and Distributors

Some coil nail machine distributors also have co-ops where you will have access to coil nailers at reduced prices. You can find coil nail machine distributors at your local hardware store or home improvement center.

When it comes to coil nail machines, always make sure you do your research before purchasing so that you can buy the best machine at a price that is right for you.

9. 6 Tips Before Buying Coil Nail Machine

When it comes to coil nail machines, there are a few things that you should keep in mind before making your purchase. Here are a few tips to help you make the best decision for your needs:

#1 Consider the Power of the Machine

Coil nail machines come in a variety of power levels, so be sure to choose one that is powerful enough for your needs. If you plan on using the machine frequently, be sure to choose one with a high power rating and a high-speed feature.

#2 Compare Prices

Coil nail machines can vary in price significantly, so be sure to compare prices before making your purchase. It’s important to find a machine that is affordable and fits within your budget.

#3 Consider the Brand

Not all coil nail machines are created equally, so be sure to choose one from a reputable brand. By choosing a machine from a well-known company, you can ensure that you’ll get the quality and durability that your machine needs.

#4 Look at the Extra Features

There are coil nail machine models available with additional features, so be sure to choose one with any available features that you’ll need. For example, machines with a touch screen feature tend to be most popular because they are easier to use.

#5 Find Coil Nail Machine Reviews

Coil nail machines are available in many different models, so be sure to do your research and find machine reviews before making your purchase.

#6 Think About the Warranty

Coil nail machines are made from different components, so be sure to choose a machine with a warranty for peace of mind.

By following these tips, you’ll be able to choose the coil nail machine that is right for your needs and budget.

10. Final Words

The coil nail machine is the perfect machine for anyone who wants to drive coil nails into a variety of materials. To choose the coil nail machine that is right for you, it’s important to do your research and compare prices before making a purchase.

With its steel construction, the coil nail machine is resistant to wear and tear, making it a long-lasting tool that you can rely on.

Contact us at Awnail and purchase the coil nail machine today!

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us