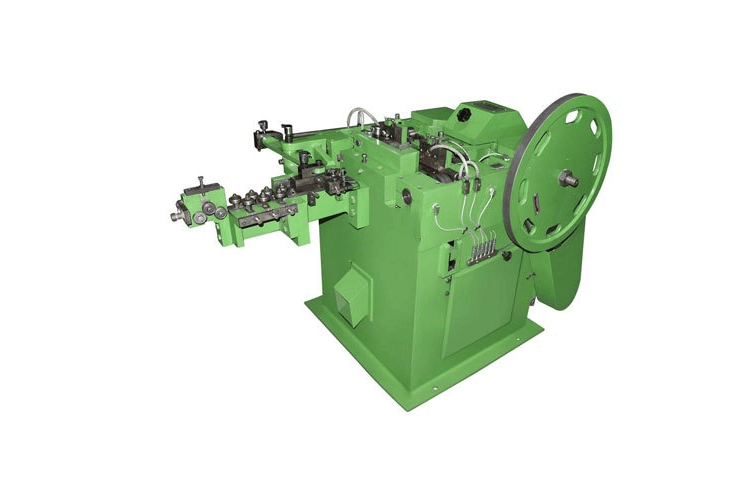

Exceptional Wire Drawing Machine For Your Business

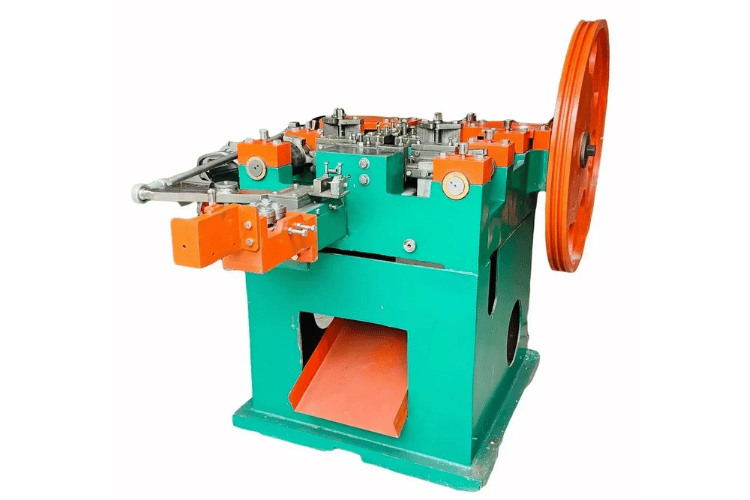

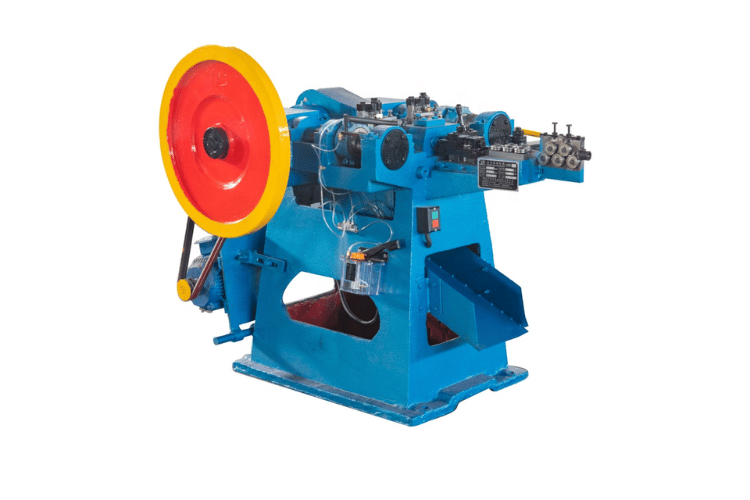

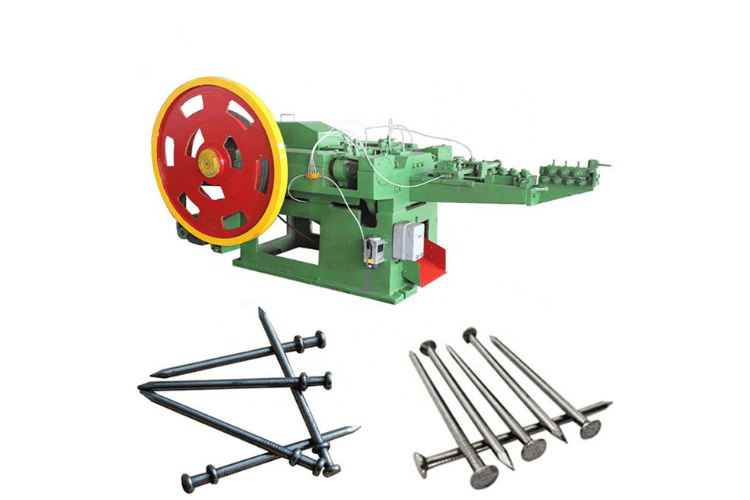

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

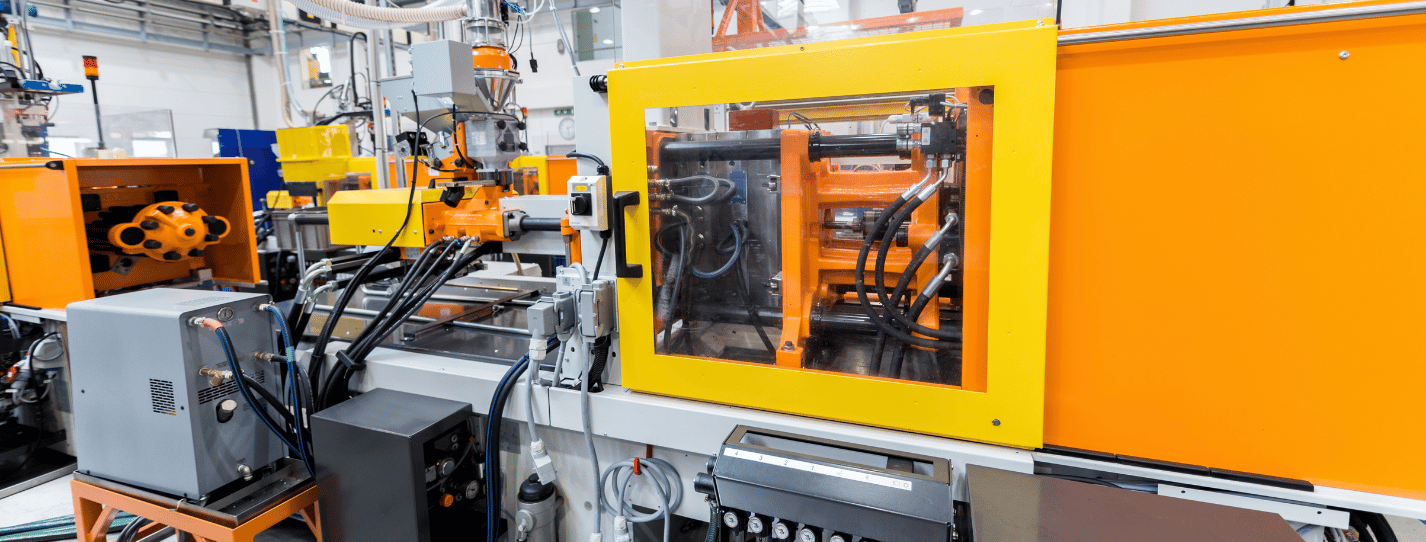

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Features of Wire Drawing Machine

Wire Thinning Technology

Integrated Cooling System

Automatic Wire Feeding Mechanism

Benefits of Wire Drawing Machine

Enhanced Productivity

Cost-Effective Operation

Reliability and Consistency

Applications of Wire Drawing Machine

Nail Manufacturing Industry

Construction Industry

Automotive and Machinery Production

Furniture and Carpentry

3 Considerations When Buying a Wire Drawing Machine

#1 Capacity and Speed

#2 Technological Features

#3 Durability and Maintenance

Dive Deeper Into Our Resources

- Discover the Top 8 Wire Drawing Machine Manufacturers

- What Is Wire Drawing?

- 11 Expert Tips on Selecting the Best Wire Drawing Machine for Your Needs

- Navigating Wire Drawing Machine Costs: A Comprehensive Buyer’s Guide

- 8 Proven Tips for Negotiating Wire Drawing Machine Prices

Wire Drawing Machine: Everything You Need to Know

When you are looking for a wire drawing machine, it is important to know exactly what you need. Not all machines are created equal, and the right one for your needs will depend on the intended use.

With the fast growth of technology and the construction industry, it is no secret that the wire drawing machine is a critical component of the manufacturing business. There is a lot of information to take in.

In this blog post, we will discuss everything you need to know. So if you’re in the market for a wire drawing machine, read on!

1. What Is a Wire Drawing Machine

A wire drawing machine is a device that allows wires to be drawn through dies of various sizes. The wire will typically start as round and then pass through smaller dies until it reaches the desired shape or thickness. It is used for wire production in different industries, such as automotive, electronics, aerospace and wire mesh manufacturing.

These machines can draw a wire of different shapes (round, square, hexagonal) and thicknesses depending on what type of die you use for wire drawing. Wire drawing machines come in a variety of types, each with its own set of advantages and disadvantages.

Wire drawing machines are also known for being able to make wire with high precision and consistency.

Some wire drawing machines feature multiple die sets, which allows them to draw wire at different speeds and sizes depending on the wire drawing machine formula simultaneously. Other wire drawing machines offer more control over the process by allowing operators to make adjustments as needed throughout production runs.

2. Different Types of Wire Drawing Machines

There are different types of wire drawing machines that are used for specific applications:

Wire Rod Drawing Machine

This type is used for making steel wires like barbed wires, chain links or garden fences, etc. It can be operated manually or with electricity. It is also known as a wire rope drawing machine.

Wire Nail Drawing Machine

Nail wire drawing machine is used to make wire nails, which will be further processed into nail art objects such as wire coil springs or other metal pieces that are bent over on themselves (like paperclips).

It has fewer moving parts than rod drawing machine, which means less maintenance required on your part as well as lower costs per unit produced over time. This type can also process different types of wire such as copper wires and aluminum wires in addition to steel wire nails.

Wire Mesh Drawing Machine

It is used for wire mesh production. The wire drawing machine can be operated manually or with electricity, depending on the type of wire you want to produce and how much time it takes to complete one cycle (from the beginning until the end).

This wire drawing machine is a high speed wire drawing machine with a spinning process to produce wire meshes at speeds up to 200 times faster than traditional wire drawing methods. The result is less time spent on production, lower costs per unit produced and higher quality products overall.

Wire mesh wire drawings are typically used in the construction industry where they are welded or crimped to form wire mesh products like window screens, wire fences and security cages.

Bar Drawing Machine

This wire drawing machine will produce wire that is thinner than the wire produced by a die drawing machine. The wire passes through bars with smaller holes until it reaches the desired size or thickness.

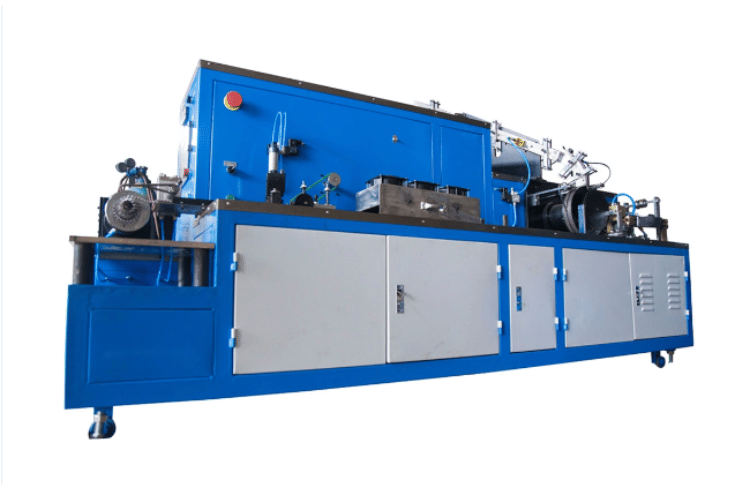

Continuous Wire Drawing Machine

This type of wire drawing equipment produces continuous lengths of wire at uniform diameters so they can be used in manufacturing processes.

Tube Drawing Machines

This wire drawing machine is used to draw wire into a tubular shape. The wire is drawn through a series of dies where it is reduced in diameter until it reaches the desired thickness.

Multi Wire Drawing Machine

This wire drawing machine can simultaneously draw wire at multiple diameters and speeds. This allows for the production of wires with different shapes and sizes.

Bull Block Wire Drawing Machine

This wire drawing machine is used to draw wire into a circular shape. The wire passes through the bull block, which has smaller holes than the die. This reduces the diameter of wire until it reaches its final size or thickness.

Wire Draw Bench Drawing Machine

A wire draw bench drawing machine is used to draw wire at a slower rate than the continuous type of machine. A drawbench has two or more dies on it and produces equal amounts of the finished product during each pass through the die set. You may be able to check wire draw bench for sale on a wire drawing machine manufacturers selling online.

Inverted Vertical Wire Drawing Machine

The inverted wire drawing machine is a type of wire drawing machine that uses a pair of rollers to pull the wire through a die. The wire is held in place by two clamps, one on each side of the die. This vertical drawing machine is used to draw wires with a small diameter. While a horizontal wire drawing machine is often used for large-diameter wire.

Horizontal Wire Drawing Machine

A wire drawing machine horizontal is used to draw wire at a faster rate than the vertical wire drawing machine. This type of machine uses a series of rollers to pull the wire through a die. The wire is held in place by two clamps, one on each side of the die. This allows for the production of wire with a large diameter.

Fine Wire Drawing Machine

A fine wire drawing machine is used to produce wire with a small diameter. This type of wire is often used in medical and electronic applications. The fine wire drawing machine has a smaller work area than the standard cable drawing machine, which allows for greater precision when creating thin wire.

Iron Wire Drawing Machine

An iron wire drawing machine is a type of wire drawing machine that uses a solid iron wire as the drawing die. This type of wire drawing machine is typically used to draw wire with a high tensile strength.

3. Different Types of Wire Drawing Machines and their Average Cost

| Types | Average Cost |

|---|---|

| Wire Rod Drawing Machine | $10,000 – $12,000 |

| Wire Nail Drawing Machine | 12,000 – 15,000 |

| Wire Mesh Drawing Machine | $15,000 – $30,000 |

| Bar Drawing Machine | $20,000 – $40,000 |

| Continuous Wire Drawing Machine | $25,000 – $50,000 |

| Tube Drawing Machines | $30,000 – $60,000 |

| Multi Wire Drawing Machine | $50,000 – $100,000 |

| Bull Block Wire Drawing Machine | $60,000 – $120,000 |

| Wire Draw Bench Drawing Machine | $80,000 – $160,000 |

| Inverted Vertical Wire Drawing Machine | $90,000 – $180,000 |

| Horizontal Wire Drawing Machine | $100,000 – $200,000 |

| Fine Wire Drawing Machine | $150,000 – $300,000 |

| Iron Wire Drawing Machine | $250,000 – $500,000 |

4. How Does a Wire Drawing Machine Work

Here is a guide of wire drawing machine process:

Step #1 Wire is Fed Into the Machine

The wire is fed into the dry wire drawing machine with the help of a pay-off reel. This wire is called input wire and from here on out, it will also be referred to as “wire” or “input wire” for clarity purposes.

Step #2 Die and Drawbench

The wire is then sent through a die, which is a cylindrical hole in the drawbench. This die will determine the size of the wire that comes out of the machine.

Step #3 Wire Travels Through Multiple Dies

After passing through the first die, the wire will travel through multiple other dies (usually two or three) to achieve the desired thickness.

Step #4 Die Grinds the Wire Down to Size

As the wire moves through each die, it is gradually ground down to size. This process is what gives wire its characteristic smooth and shiny finish.

Step #5 Wire Comes Out of Machine

Once the wire has gone through all the dies, it will come out of the drawing machine wire and be ready for use.

Step #6 Wire Falls Into a Recoiler

The recoiler is responsible for collecting wire as it comes out, making sure that there are no tangles or knots. This way when wire needs to be used again, it can just be taken off without having any issues.

As you can see, wire drawing machines are an essential part of the manufacturing process for wires of all shapes and sizes. By understanding how they work, you can ensure that your products are made with the highest quality possible.

Here’s a video of the wire drawing machine operation!

5. Advantages of Using a Wire Drawing Machine

Here are some advantages to wire drawing machines, which is why they remain one of the most popular ways to draw wire.

Improved Productivity

With the wire drawing machine production calculation of products, it allows you to get more work done in less time than other methods such as hand wire drawing techniques or manual labor. This means that your business can run more efficiently and produce more products in a shorter amount of time.

Consistent Quality

Wire drawing machines provide a more consistent product quality than other methods. This is because the wire is drawn through multiple dies, which results in a smoother and shinier finish.

Increased Efficiency

Wire drawing machines can achieve wire sizes that are not possible with other methods like hand wire drawing techniques or manual labor. This means that your business can produce more wire faster without having to sacrifice any quality control standards.

Cost Savings

Wire drawing machines are generally less expensive than their competitors because they require less human resources and maintenance costs over time (i.e. no need for many wire drawing machine operator). Some manufacturer requires training as written in the wire drawing machine operator job description but some just needs basic knowledge on operating the machine.

6. 5 Things To Consider Before Purchasing a Wire Drawing Machine

Here are 5 things to consider before buying a wire drawing machine.

#1 Decide on the Size and Thickness of Wire You Need

Before purchasing a wire drawing machine for sale, you need to first decide the size, wire drawing machine specification and thickness of wire that you need. This will help narrow down your options and make it easier to find a machine that meets your specific requirements.

#2 Consider Your Budget

It is important to consider your budget when choosing wire drawing machines. There are many different types and styles of wire drawing equipment available on the market today, so it is important to find one that meets both your requirements as well as fits within your price range.

#3 Consider How Many Wires You Want To Draw at Once

Before purchasing wire drawing machines, you should consider how many wires you want to draw at once. This will help ensure that the wire drawing machine you choose can handle your production needs.

#4 Consider How Many Dies You Need and What Size They Are

When purchasing wire drawing machines, it is important to consider the number of dies and what size they are. A wire drawing machine with more dies can handle wire of different sizes, while a wire drawing machine with larger dies can achieve thicker wire thicknesses.

#5 Consider the Maintenance and Operating Costs

When purchasing wire drawing machines, it is important to consider the wire drawing machine price, maintenance and operating costs. This will help you determine how wire drawing machine cost to operate over time as well as the ongoing maintenance costs.

7. Components of a Wire Drawing Machine

The wire drawing machine consists of the following components:

Die Holder

The die holder is the component that holds the dies in place. It is attached to the wire drawing machine and allows the wire to be drawn through the dies.

Die Plate

The die plate is a flat piece of metal that has multiple holes drilled into it. These holes correspond to the size of the wire that you want to draw. The die plate is attached to the metal drawing machine and allows the wire to be drawn through it using dies.

Wire Drawer/Operator

The wire drawer or operator is responsible for operating the wire drawing machine. They will load wire into molds, heat them until they melt down into liquid form, then pour this molten metal into molds that have been drilled out with holes to match wire thicknesses.

Wire Feeders

The wire feeders are responsible for feeding wire into the wire drawing machine. They will place the wire in molds, heat them until they melt down into liquid form, then pour this molten metal into molds that have been drilled out with holes to match wire thicknesses.

Wire Cutter

The wire cutter is a device that cuts wire as it is being drawn through the wire drawing machine. It is typically a guillotine-style cutter and is used to trim the wire to the desired length.

Lubrication System

The wire drawing machine has a lubrication system to help keep the wire from getting caught on other components. This may include oil or grease that is sprayed onto the wire during the operation of the wire drawing machine.

Control System

A computerized control system can be used to operate the wire drawing machine, including starting/stopping it and changing settings such as wire-speed, temperature, and the amount of lubrication that is applied. This system can be used to monitor wire drawing operations and collect data for quality control purposes.

It’s important to note that wire drawing machines can be manual or automatic wire drawing machine.

8. How To Select the Right Wire Drawing Machine for Your Needs

When it comes to wire drawing machines, there are a lot of factors to consider. Here are some tips on how to choose the best machine for your business:

Choose Right Size of Machine

Choose a wire drawing machine that is the right size for your needs. You don’t want a machine that’s too big or too small, so make sure you have the specs of the machine in hand before you make your purchase.

Choose Brand of Wire Drawing Machine

Consider the brand of wire drawing machine you’re purchasing. Not all machines are created equal, so be sure to do your research on the different brands available.

Choose Your Budget

Think about your budget and how much you’re willing to spend on a wire drawing machine. There are many different wire drawing machines available for sale, so you must do your research before making a purchase.

Consider the Right Type of Machine

Think about the amount of time and effort you’re willing to put into the wire drawing machine. There are wire drawing machines that take less than an hour to complete, while others may take several days or weeks. It’s important to choose the wire drawing machine that’s best for your needs.

Choose a Reputable Manufacturer

It is important to choose a wire drawing machine manufacturer that is reputable such as Awnail. A wire drawing machine exporter should have a good reputation and be able to provide you with the best quality wire drawing machines available.

Make sure you have a good understanding of how the wire drawing machine works before making a purchase. There are many different machines available on the market, so be sure to do your research and find the one that’s right for you.

9. 9 Maintenance and Troubleshooting Tips for Wire Drawing Machines

Here are several tips on how to maintain and troubleshoot a wire drawing machine.

#1 Keep the Wire Drawing Machine Clean

It is important to keep the wire drawing machine clean to ensure optimal performance. Dust and debris can build up on the die plate, in the quench tank, and around the wire guide, which can cause problems with wire quality and speed.

#2 Use the Correct Lubrication System for Your Wire Diameter

If you are using a wire drawing machine to draw wire with a diameter larger than .020″, it is important to use a lubrication system. The wrong type of lubrication can cause damage to the wire and the wire drawing machine.

#3 Keep the Quench Tank Full

The quench tank should be kept full of water or oil to help cool the wire after it has been drawn through the wire drawing machine.

#4 Check the Wire Guide for Wear and Tear

The wire guide is a critical component of the wire drawing machine. It is important to check it regularly for wear and tear and replace wire drawing machine parts as needed.

#5 Keep the Die Plate and Wire Guide Clean

The die plate and wire guide should be cleaned regularly to ensure optimal wire quality. They can become dirty with dust and debris over time, which can cause problems with wire speed and quality.

#6 Replace the Wire Guide as Needed

It is important to check the wire guide for wear & tear regularly. If it is found to be worn, it should be replaced immediately. Wire drawing machine spare parts should always be readily available.

#7 Keep the Die Plate and Wire Guide Lubricated

The die plate and wire guide should be lubricated regularly with a light coating of oil or grease. This will help to reduce friction and increase wire speed.

#8 Check the Quench Tank for Debris

The quench tank should be checked regularly for debris and cleaned as needed. Debris can cause problems with wire quality and speed.

#9 Check the Wire Drawing Machine for Proper Operation

It is important to check the steel drawing machine for proper operation regularly. If there are any problems, troubleshoot and fix them as soon as possible to avoid wire drawing machine accident.

Wire drawing machines are an essential piece of equipment for a steel wire drawing machine manufacturer. By following the maintenance and troubleshooting tips listed above, you can help ensure that your wire drawing machine operates at its optimal level.

10. Conclusion

Wire drawing machines are an important investment for any business. If you take the time to consider all of the factors we’ve outlined in this post, you should be able to find a machine that will perfectly suit your needs.

Contact us today at Awnail and our team of experts will help you find the perfect wire drawing machine for your business. We look forward to hearing from you soon.

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us