Ever considered how thread rolling machines are transforming the custom fabrication industry? These powerful tools not only enhance efficiency but also redefine the quality of end products in this sector.

With years of expertise in the field of thread rolling technologies in custom fabrication and a deep understanding, I bring a wealth of knowledge that is both practical and relevant to today’s industrial landscape.

The impact of thread rolling machines in custom fabrication is profound and multifaceted. These machines not only streamline production but also ensure the consistent quality of products.

In this ultimate guide, discover the important role of these machines. We will delve into the latest innovations, best practices, and strategic applications of thread rolling machines in custom fabrication.

Read on to get more insights.

1. The Role of Thread Rolling in Custom Fabrication

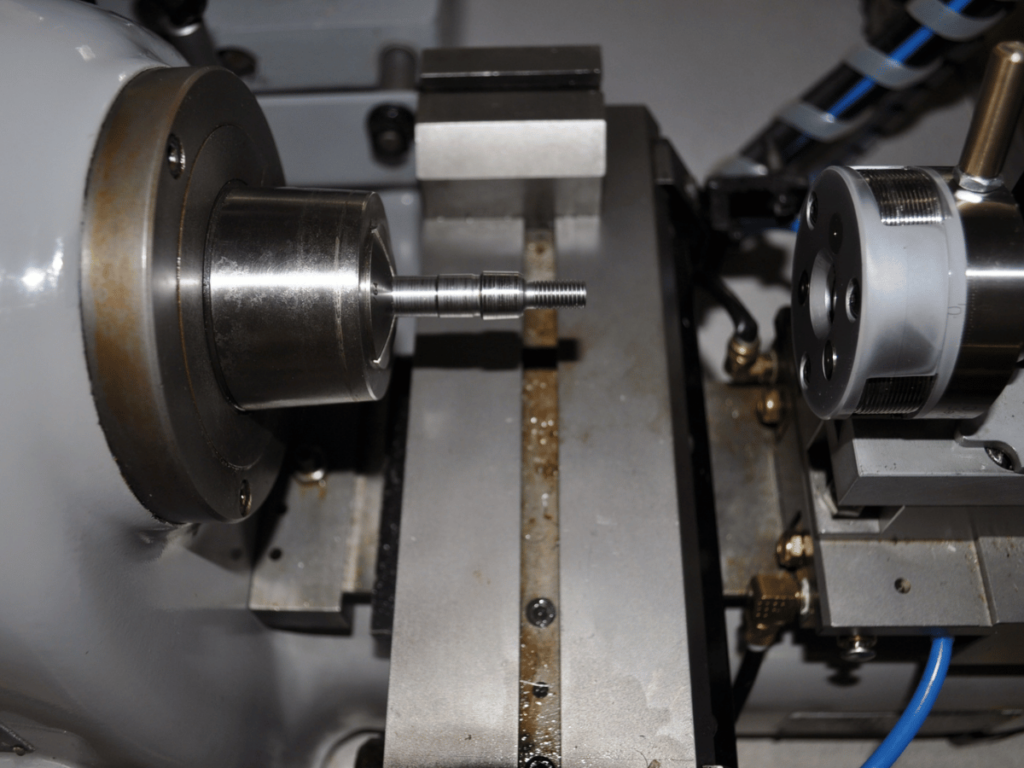

Thread rolling, a process of forming threads by precisely shaping metal, stands as a cornerstone of modern fabrication. This technique not only offers exceptional strength and accuracy but also significantly reduces material waste compared to traditional cutting methods. Its ability to produce uniform, high-quality threads quickly is particularly advantageous for manufacturers aiming for efficiency and consistency.

By employing thread rolling, custom fabrication businesses can tackle complex projects with confidence, knowing that the integrity and durability of their products are enhanced. This method not only streamlines production but also ensures that the final products meet the strict demands of diverse industries, from automotive to aerospace.

2. Advantages of Using Thread Rolling Machines in Custom Fabrication

Recognizing the important role of thread rolling in custom fabrication leads us to explore its numerous advantages. Let’s see the key benefits that thread rolling machines offer in this sector:

- Enhanced Product Strength and Durability: Thread rolling machines produce threads with improved tensile strength and fatigue resistance. This is essential for applications where durability is paramount, such as in the construction or automotive industries.

- High Efficiency and Productivity: These machines enable rapid production without compromising on quality, significantly increasing throughput. This efficiency is essential for meeting tight deadlines and maintaining a competitive edge in the market.

- Cost-Effectiveness: By reducing material wastage and lowering tool costs, thread rolling machines offer a cost-effective solution. This aspect is particularly attractive for businesses looking to optimize their production budgets.

- Superior Thread Quality and Consistency: The threads produced are uniform and have a high-quality finish, which is crucial for ensuring the reliability and performance of fabricated products.

- Versatility in Fabrication: Thread rolling machines can handle a wide range of materials and thread specifications,making them a versatile tool in custom fabrication setups, adaptable to various project requirements.

3. Opportunities Presented by Thread Rolling in Custom Fabrication

Building on the advantages of thread rolling machines, it’s essential to explore the opportunities they present in custom fabrication. Here are key areas where these machines can significantly enhance business prospects:

Expansion into New Markets

Thread rolling technology opens doors to new market segments, particularly where precision and durability are non-negotiable. Thread Rolling Machines Market size is projected to reach USD XX Billion by 2030 according to LinkedIn. For instance, in the aerospace and automotive industries, the demand for high-strength and reliable components is constant. Adopting thread rolling in business can cater to these industries’ needs.

Increased Customization Capabilities

Custom fabrication often requires versatility to meet unique client specifications. Thread rolling machines provide this flexibility, enabling manufacturers to produce a wide range of thread sizes and profiles. This adaptability is crucial for businesses aiming to offer tailored solutions to their clients. For example, a company could utilize these machines to create specialized bolts for a unique construction project.

Streamlining Production Processes

Thread rolling machines are integral to optimizing production lines. Awnail integrating machines can achieve faster turnaround times without sacrificing quality. This efficiency is important in today’s fast-paced market, where meeting deadlines can be as important as the quality of the work. Streamlined processes also mean better resource allocation, allowing businesses to innovate and grow.

4. Innovations and Technological Advancements

The exploration of opportunities in thread rolling for custom fabrication naturally leads us to the innovations and technological advancements that drive this field forward. Let’s explore cutting-edge developments:

Automated Control Systems

Modern thread rolling machines have embraced automation, significantly enhancing precision and efficiency. These advanced systems allow for more accurate adjustments and consistent production quality. For instance, computer-controlled setups enable operators to fine-tune the thread rolling process, adapting to different materials and specifications with ease.

Material and Design Innovations

The evolution of materials and design in thread rolling machines has been a game-changer. Manufacturers now use more durable materials for the dies and components, extending the lifespan of the machines and reducing maintenance needs. For example, the use of high-grade steel alloys in die construction allows for longer operational periods without wear, ensuring consistent thread quality over time.

Integration with Industry 4.0 Technologies

Thread rolling machines are increasingly becoming part of the Industry 4.0 transformation, integrating with IoT (Internet of Things) and data analytics tools. Awnail is utilizing these technologies to monitor machine performance and predict maintenance needs, minimizing downtime. The integration with IoT enables real-time data collection and analysis, allowing for continuous improvement in the thread rolling process.

5. Applications of Thread Rolling in Custom Fabrication

Innovations and advancements in thread rolling machines have broadened their applications in custom fabrication. These applications demonstrate the versatility of these machines. Here are some to take note of:

Aerospace and Aviation Components

The aerospace and aviation industry demands components that are both lightweight and strong. Thread rolling excels in this area by providing high-precision threads crucial for the safety and functionality of aircraft parts. Components like bolts, fasteners, and landing gear pins benefit from the high tensile strength and fatigue resistance offered by thread rolling.

Automotive Manufacturing

In the automotive sector, thread rolling is used to produce durable threads for engine bolts, transmission shafts, and steering components. The process’s ability to maintain material integrity and strength is essential for these high-stress automotive applications. Thread rolling also contributes to the lightweight design of automotive parts, which is increasingly important for fuel efficiency and performance.

Construction and Infrastructure

Thread rolling finds significant application in the construction industry, particularly in the creation of fasteners and structural bolts. These components require high strength and reliability to ensure the safety and longevity of buildings and infrastructure. The thread rolling process provides uniform, high-quality threads that are essential for the structural integrity of construction projects.

6. Challenges and Limitations in Using Thread Rolling Machines

While the applications of thread rolling in custom fabrication are wide and varied, it’s important to acknowledge the challenges and limitations inherent in using these machines. See the following key points:

Initial Investment Cost

The high cost of advanced thread rolling machines can be a significant barrier for small to medium-sized enterprises. This initial investment is often a major consideration, particularly for businesses operating with limited budgets.

Technical Skill Requirements

Operating thread rolling machines requires specialized technical knowledge and skills. Finding and training skilled operators can be a challenge, especially in regions with a limited skilled workforce.

The table below outlines the essential technical skill requirements for operating these machines, along with strategies for addressing the challenge of finding and training skilled operators, particularly in areas where the skilled workforce may be limited.

| Skill Requirement | Description | Addressing Workforce Challenges |

| Machine Operation | Proficiency in setting up and operating thread rolling machines, including adjustments for different thread types and sizes. | Training Programs: Develop in-house training programs or collaborate with vocational schools to train potential employees. |

| Technical Understanding | A deep understanding of the mechanics of thread rolling machines and the principles of thread formation. | Continuous Learning: Encourage continuous learning and professional development opportunities for employees. |

| Quality Control | Ability to inspect threads for quality and conformity to specifications, using various measurement tools. | Certification Courses: Invest in certification courses for employees to enhance their quality control skills. |

| Maintenance and Troubleshooting | Skills in performing routine maintenance and troubleshooting common issues with thread rolling machines. | Workshops and Seminars: Host workshops and seminars led by machine manufacturers or industry experts. |

| Material Knowledge | Knowledge of different materials used in thread rolling and their properties, such as tensile strength and malleability. | On-the-Job Training: Provide comprehensive on-the-job training, focusing on material handling and characteristics. |

| Safety Procedures | Understanding of and adherence to safety protocols and procedures to prevent accidents and injuries. | Safety Training: Implement regular safety training sessions and drills to ensure adherence to safety standards. |

| Efficiency Optimization | Skills in optimizing the thread rolling process for maximum efficiency and minimal waste. | Mentorship Programs: Pair experienced workers with new employees for mentorship on best practices and efficiency optimization. |

| Adaptability | Ability to adapt to new technologies and processes as thread rolling machinery and techniques evolve. | E-Learning Platforms: Utilize e-learning platforms offering updated courses on the latest technologies and industry trends. |

Material Limitations

While thread rolling is versatile, it has limitations in the types of materials it can effectively process. Harder materials or those with unique properties may pose challenges, requiring alternative methods or specialized equipment.

Maintenance and Upkeep

Regular maintenance is crucial to ensure the longevity and efficiency of thread rolling machines. Neglecting maintenance can lead to decreased productivity and increased downtime, impacting overall production.

Adapting to Rapid Technological Changes

The fast pace of technological advancements in manufacturing can make it challenging for businesses to keep their thread rolling equipment up-to-date. This constant need for upgrades can be financially and logistically demanding.

7. Economic Impact of Thread Rolling Machines in the Industry

The challenges and limitations of thread rolling machines, while significant, are balanced by their profound economic impact on the industry. See the following sections that explore this impact in detail:

Enhanced Product Quality

Thread rolling machines significantly elevate the quality of products, which in turn enhances a business’s competitiveness in the market. High-quality threads are essential in many industries, and the ability to consistently produce them can set a company apart. This improved market competitiveness often leads to increased sales and a stronger market position, contributing positively to a company’s economic standing.

Supply Chain Optimization

The efficiency of thread rolling machines impacts the entire supply chain. By reducing production times, businesses can respond more quickly to market demands, improving supply chain dynamics. This responsiveness not only benefits the manufacturing business but also positively affects distributors and end-users. Efficient supply chains are more cost-effective and reliable, leading to economic benefits in the market.

Long-term Sustainability and Economic Resilience

Investing in thread rolling machines contributes to long-term sustainability and economic resilience. By producing more durable and higher-quality components, businesses can reduce the frequency of replacements and repairs, leading to long-term cost savings for both the manufacturer and the end-user. Furthermore, the adoption of advanced technologies like thread rolling prepares businesses to adapt to future market changes.

Dive Deeper Into Our Resources

For some insightful reads, we’ve curated a list of recommended articles just for you:

- Exploring the Diverse Industrial Uses of Thread Rolling Machines

- How To Start a Nail Manufacturing Business?

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

In this comprehensive guide, we’ve gone through the complex landscape of thread rolling machines, highlighting their important role in enhancing production efficiency and product quality. This exploration equips businesses with the knowledge to make informed decisions in pursuit of advanced manufacturing solutions.

For businesses looking to integrate these powerful tools into their operations, Awnail offers a range of top-tier thread rolling machines tailored to your specific needs. Contact us today to learn more.