Has anyone wondered how the quality of wire can drastically alter the outcome in nail manufacturing? This key component is vital in determining the final product’s integrity.

Drawing from extensive research and industry insights, I offer a comprehensive analysis on the importance between wire quality and its impact on nail production processes.

Here’s a sneak peek into 2 of the significant influences of wire quality:

- Durability Enhancement

- Precision in Nail Design

In this guide, we explore the profound effects these elements have on the efficiency and quality of nail manufacturing.

Read on to delve into the world of nail manufacturing.

1. Durability Enhancement

The durability of nails is profoundly influenced by the quality of the wire used in their manufacturing. Superior wire quality ensures nails are more resistant to bending, breaking, and corrosion, making them suitable for various applications. Here are some key points:

- Material Composition: High-quality wire, characterized by optimal carbon and alloy content, ensures greater strength and longevity of the nails. This results in nails that can withstand demanding conditions without compromising their structural integrity.

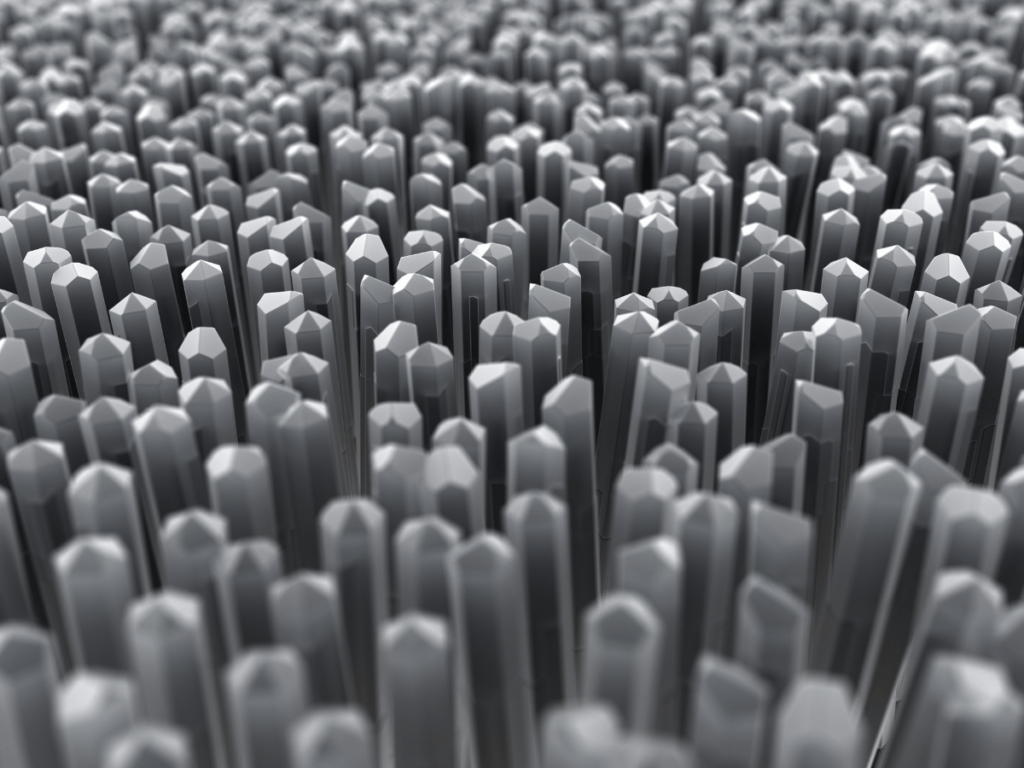

- Consistent Wire Diameter: Consistency in wire diameter, indicative of superior wire quality, is vital for ensuring that nails have uniform strength throughout. Uniform diameter prevents weak spots in nails, enhancing their ability to bear loads and resist environmental stresses.

- Corrosion Resistance: Superior wire quality often includes enhanced corrosion resistance, crucial for nails used in outdoor or humid environments.This ensures a longer lifespan and maintains the nail’s appearance and functionality over time.

2. Precision in Nail Design

In nail manufacturing, precision in design is critically dependent on wire quality. The caliber of wire used dictates the nail’s dimensional accuracy, structural integrity, and overall aesthetic. Let’s explore the key aspects where wire quality is fundamental to nail design precision:

- Accurate Dimensions: High-quality wire allows for precise control over nail dimensions, ensuring each nail is uniformly produced to exact specifications. This is essential for specialized applications where size consistency is critical.

- Consistent Shaping: Superior wire quality facilitates more consistent shaping during the manufacturing process, leading to nails with uniform heads and points. For example, in construction, uniform nail heads ensure easier and more reliable application.

- Flawless Finish: The use of premium wire not only aids in achieving structural precision but also contributes to a more aesthetically pleasing finish. This enhances the visual appeal of the nails, reflecting a commitment to quality and attention to detail.

3. Efficient Production

Efficient production in nail manufacturing hinges significantly on the quality of wire used. High-grade wire not only streamlines the manufacturing process but also minimizes waste and enhances machine longevity. Let’s delve into these benefits in detail:

- Streamlined Manufacturing Process: Using superior quality wire leads to a smoother, more efficient manufacturing process, reducing downtime and increasing output rates.

- Minimized Material Waste: High-quality wire ensures consistent production without defects, significantly reducing material waste. For example, fewer misshapen nails mean less scrap and rework, optimizing resource utilization.

- Extended Machinery Life: Premium wire quality, as utilized by leading brands like Awnail, results in less abrasion on machinery. This leads to reduced wear and tear, proving to be a significant factor in lowering maintenance costs and boosting production efficiency over time.

4. Strength and Sturdiness

The strength and sturdiness of nails, crucial for their performance, are greatly influenced by the wire quality used in manufacturing. High-quality wire ensures that nails are not only strong but also reliable under various conditions. Here are some key aspects:

- Increased Tensile Strength: Nails made from superior quality wire exhibit higher tensile strength, allowing them to endure greater forces without snapping.

- Resistance to Deformation: Quality wire ensures that nails maintain their shape and do not bend easily under pressure, crucial for structural stability.

- Enhanced Endurance in Varied Conditions: Using high-caliber wire results in nails that are more robust in facing diverse environmental challenges like corrosion and temperature fluctuations. This resilience is vital for maintaining the integrity of projects over time.

5. Technological Advancements

Technological advancements in nail manufacturing are significantly enhanced by the use of high-quality wire. The integration of cutting-edge technologies with premium wire results in more efficient, precise, and innovative nail production. Here’s how these advancements manifest:

- Enhanced Production Speed: Superior wire quality facilitates faster production speeds, as advanced machinery can operate more efficiently with high-grade materials.

- Integration with Cutting-Edge Coatings: The use of high-grade wire allows for better adherence and effectiveness of advanced coating extending the nail’s lifespan and functionality. This integration is crucial in delivering products that meet modern demands.

- Optimized for Automated Processes: Superior wire quality is essential for the smooth operation of automated manufacturing systems and increasing production efficiency. Awnail, utilizing such technologies, exemplifies how quality wire can elevate the entire production process.

6. Environmental Sustainability

Environmental sustainability in nail manufacturing is closely linked to the quality of wire used. Superior wire quality can lead to more eco-friendly manufacturing processes, reduce waste, and extend the product’s life cycle. Here are some critical points in this regard:

- Efficient Use of Resources: The use of top-grade wire ensures that resources are utilized more efficiently during the manufacturing process. This efficiency not only benefits the environment but also resonates with a commitment to sustainable practices.

- Longer Product Lifespan: Nails made from superior wire last longer, meaning less frequent replacement and, consequently, a reduction in resource usage and waste generation over time.

- Improved Recyclability: High-quality wire enhances the recyclability of nails, aligning with the global trend where about 85-90% of steel is recycled, as per LinkedIn. This effective recycling of nails contributes to a smaller ecological footprint and supports the principles of a circular economy.

Here’s a table that outlines the importance of improved recyclability in nail production, especially focusing on the use of high-quality wire:

| Aspect | Description | Impact |

| Improved Recyclability | Use of high-quality wire in nail production enhances the recyclability of nails. | Environmental Sustainability: Contributes to reducing ecological footprint by facilitating effective recycling. |

| Global Recycling Rates | Approximately 85-90% of steel is recycled globally, highlighting the significant potential for recycling nails made of steel wire. | Circular Economy Support: Aligns nail production with global sustainability efforts by maximizing material reuse. |

7. Market Trends and Consumer Preferences

The wire quality in nail manufacturing not only affects the product’s performance but also aligns with evolving market trends and consumer preferences. High-quality wire caters to the market’s demand for reliability, versatility, and application-specific nails. Let’s delve into how these preferences shape the industry:

- Increased Demand for Specialty Nails: Consumers and professionals are seeking nails tailored for specific purposes, which high-quality wire can uniquely provide.

- Versatility in Applications: The versatility of nails, influenced by the quality of wire, is a key factor in consumer choice.It’s fascinating to see how a simple component like wire can significantly broaden the range of applications for nails.

- Preference for High-Strength and Low-Maintenance Nails: The market leans towards nails that offer high strength and require minimal maintenance. Using premium wire quality addresses these preferences by producing nails that maintain their integrity over time.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

This exploration into the impacts of wire quality on nail manufacturing highlights its vital role in ensuring product excellence and meeting industry standards. Understanding these aspects can greatly aid in making informed decisions for efficient and sustainable nail production.

For those seeking top-tier nail manufacturing solutions, Awnail is the go-to expert. To learn more or to collaborate, please contact us today.