Are you aiming to utilize the full potential of your thread rolling machine? These complex pieces of equipment are pivotal in mass-producing threads with precision and speed, yet many fail to utilize them to their fullest capacity.

As an expert in the thread rolling machine industry, I bring years of hands-on experience and deep technical knowledge to the table. My insights are grounded in real-world applications and continuous innovation, making me a reliable source for enhancing your machine’s productivity.

Here’s a sneak peek at the top 2 strategies for maximizing the productivity of your machine:

- Optimal Machine Setup for Enhanced Performance

- Mastering Machine Parameter Adjustments

In this guide, you’ll uncover a comprehensive approach to optimizing your thread rolling operations. From fine-tuning your machine’s settings to adopting best practices in maintenance, we aim to equip you with the knowledge to outperform the competition.

Read on for your waiting success!

1. Optimal Machine Setup for Enhanced Performance

To begin with, achieving the peak of productivity in thread rolling operations depends on the machine setup. An optimal setup not only enhances performance but also ensures consistent quality in output. Here are the key strategies to achieve this:

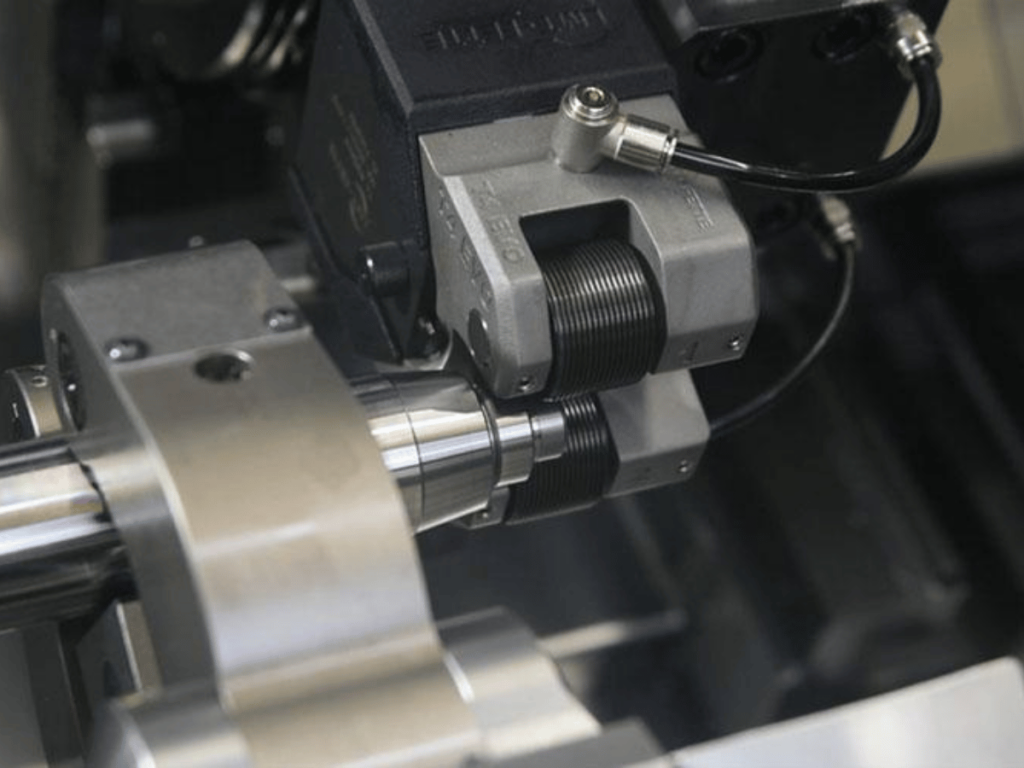

Alignment of Dies

Proper alignment of the thread rolling dies is crucial for uniform thread production. Misalignment can lead to defects and increased wear on the machine, reducing its lifespan. Ensure that the dies are aligned perfectly with each other to produce threads that meet specifications without causing unnecessary strain on the machine.

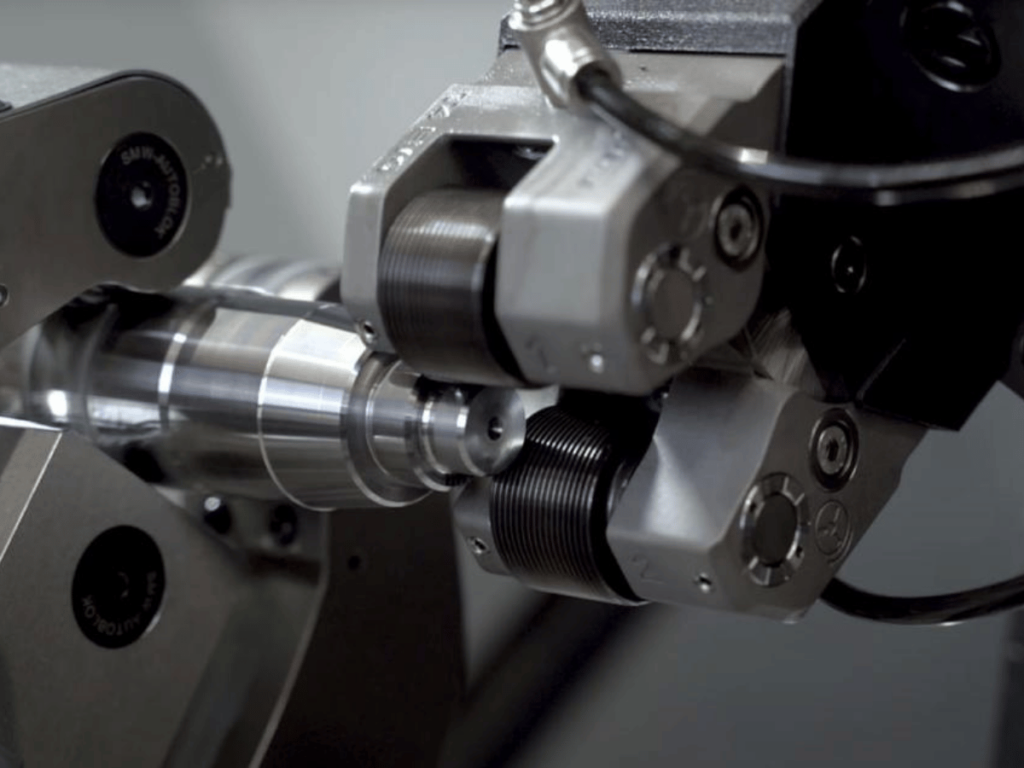

Suitable Rolling Speed and Pressure

The speed and pressure settings play a vital role in the quality of the threads produced. Too high a speed or too much pressure can damage the material or the dies, while too low settings can lead to poor thread formation. Finding the right balance based on the material and thread specifications is key to maximizing productivity.

Quality Dies and Materials

High-quality dies and materials are essential for efficient thread rolling. Using premium dies ensures precision and longevity, reducing the need for frequent replacements. Similarly, selecting the right material for your threads can prevent issues such as cracking or poor thread formation, leading to higher productivity and less waste.

2. Mastering Machine Parameter Adjustments

Another strategy in maximizing the productivity of your thread rolling machine lies in mastering its parameter adjustments. Fine-tuning these settings can lead to significant improvements in efficiency and product quality. Here are the essential adjustments to consider:

Pitch and Diameter

The correct pitch and diameter settings are crucial for producing threads that match the desired specifications. The desired pitch varies depending on the application which directly affects the thread’s grip and strength. Similarly, the diameter must be set precisely to ensure the thread fits perfectly with its mating part. Regular calibration ensures these settings are accurate, ensuring the final product meets customer expectations.

Feed Rate Optimization

The optimal feed rate depends on the material being threaded and the specific thread characteristics required. For softer materials, a faster feed rate can be used without damaging the material or the dies. While harder materials often require a slower feed rate to prevent damage and ensure a clean thread cut. The desired feed rate must be set properly to maximize the output without compromising the integrity of the thread.

Temperature Management

Maintaining an optimal temperature during the threading process is crucial, especially for thermally sensitive materials. The desired temperature range varies depending on the material, but it should be controlled to prevent any heat-induced alterations in material properties. For example, metals might require a cooler environment to prevent expansion, while some plastics may need a warmer setting to remain malleable.

3. Routine Maintenance for Consistent Output

The next strategy to ensure your thread rolling machine maintains high productivity levels is through routine maintenance. Regular checks and servicing can prevent unexpected downtimes and maintain consistent output quality. Here are the specific maintenance practices to implement:

Regular Cleaning

Regular cleaning is essential to remove debris, dust, and lubricant build-up that can affect machine performance. A clean machine experiences fewer operational issues, leading to less downtime and more consistent output. This practice should be performed daily, focusing on the dies, feed mechanisms, and any areas prone to accumulating debris.

Component Inspections

Inspecting the machine components every other operations is vital to prevent unexpected failures. Focus on critical areas such as the dies, bearings, and any mechanical linkages that are subject to wear. Early detection of damage allows for timely repairs, avoiding more significant issues that can arise from neglect. Scheduled inspections should be part of the maintenance routine, with immediate action taken on any identified issues.

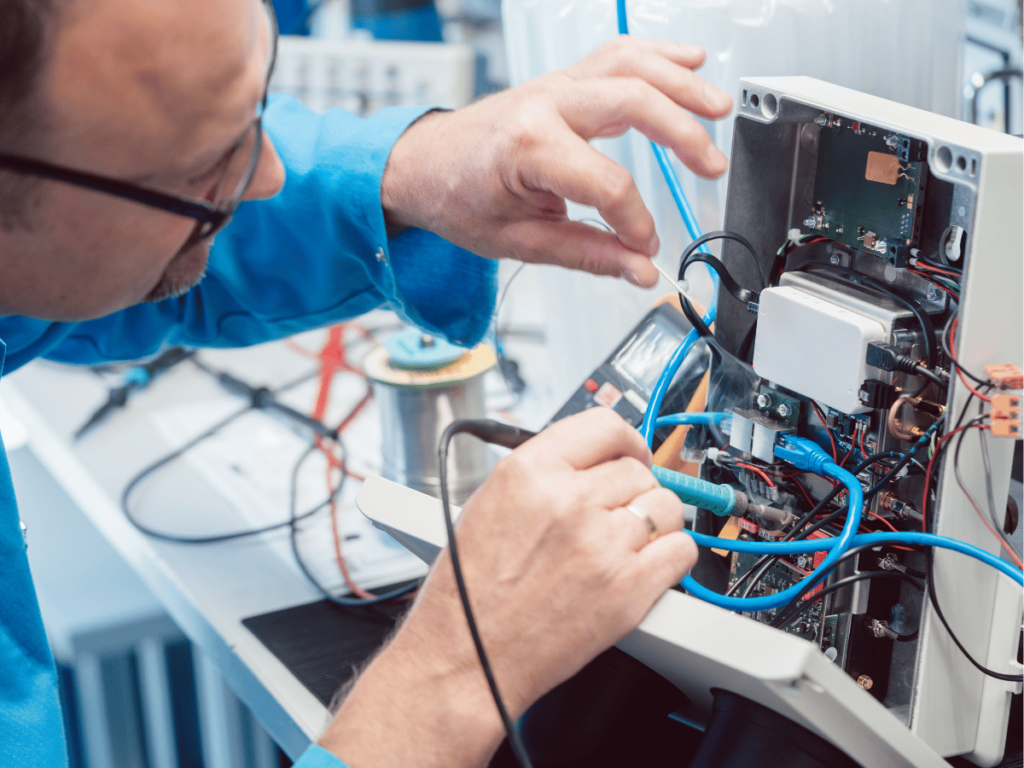

Software Updates

For thread rolling machines equipped with digital controls, software updates are a crucial aspect of maintenance. These updates can enhance machine performance, introduce new features, and correct software bugs. Staying current with software updates ensures the machine operates with the latest improvements and security patches, leading to more efficient and reliable operations.

4. Troubleshooting Common Issues

The next strategy to maximize the productivity of your thread rolling machine involves adept troubleshooting of common issues. Quick identification and resolution of these problems are essential for reducing downtime and maintaining efficient operations. Here are some common issues and its solutions:

Misaligned Dies

Misaligned dies can lead to poor thread quality and increased wear on the machine. To troubleshoot, first, check the alignment of the dies according to the manufacturer’s specifications. Use precision measuring tools to ensure that the dies are parallel and correctly positioned relative to each other. Regularly rechecking and adjusting the alignment can prevent this issue from recurring and ensure high-quality threading.

Inconsistent Thread Quality

Inconsistent thread quality can be caused by incorrect machine settings, worn-out dies, or improper material feed. Start by examining the dies for wear and replace them if necessary. Next, review and adjust the machine settings such as feed rate, pressure, and temperature to match the material’s requirements. Ensuring consistent material quality and correct machine setup can dramatically improve thread consistency.

Operational Overloads

Operating the machine beyond its capacity can lead to frequent breakdowns and reduced lifespan. If signs of overload, such as excessive noise, vibration, or heat, are present, immediately reduce the load to within recommended limits. Check the machine’s operational manual for maximum capacity guidelines and adjust your production schedule accordingly.

5. Leveraging Advanced Techniques and Innovations

Embracing advanced techniques and the latest innovations is crucial for staying ahead in the competitive landscape of thread rolling. Below are the advancements that can enhance the quality of output of your machines:

Automated Control Systems

With the steady increase in thread rolling machine production having 1.8% annually from 2012 to 2022 as reported by Index Box, the integration of automated control systems becomes crucial. Machines like those from Awnail now feature such technology that enhances efficiency, allowing operators to finely adjust parameters. This automation offers quality in production, aligning with the industry’s growth.

Eco-Friendly Lubrication Systems

Implementing eco-friendly lubrication systems not only protects the environment but also enhances machine performance. These systems provide consistent lubrication, reducing wear and tear on the machine and dies. By using eco-friendly lubricants, Awnail aims to improve sustainability practices while ensuring their machines operate smoothly.

Real-Time Monitoring and Analytics

Utilizing real-time monitoring and analytics tools enables businesses to optimize their thread rolling processes actively. These tools provide valuable insights into machine performance, allowing for immediate adjustments to improve efficiency and reduce downtime. Monitoring systems can also predict maintenance needs, preventing unexpected machine failures.

6. Maximizing Operator Skill and Safety

Ensuring the skill and safety of operators is key to maximizing the productivity and efficiency of thread rolling machines. A well-trained operator not only enhances machine performance but also minimizes the risk of accidents. Here are essential practices to achieve this:

Training Programs

Comprehensive training programs are crucial for equipping operators with the necessary skills and knowledge to operate thread rolling machines efficiently. These programs should cover machine operation, troubleshooting, and safety protocols. Well-trained operators can also identify and address potential issues before they escalate which can reduce downtime and maintaining consistent production quality.

Regular Safety Audits

Regular safety audits are essential to identify potential hazards in the workplace and ensure compliance with safety standards. These audits should assess all aspects of the operation, including machine safety features, operator practices, and the condition of the work environment. Implementing the recommendations from these audits helps to prevent accidents, ensuring a safe working environment for all employees.

Ergonomic Workstations

Ergonomic workstations are designed to minimize operator risk of injuries, particularly from repetitive tasks. For example, adjusting the height of control panels and ensuring that all tools and materials are within easy reach can significantly improve operator comfort. A comfortable design can help operators maintain high levels of productivity throughout their shifts which enhances safety.

7. Efficient Workflow and Process Optimization

Optimizing the workflow and processes around thread rolling machines is critical for achieving maximum productivity and efficiency. Streamlining operations can significantly reduce downtime and increase output quality. Here are the key strategies for process optimization:

Production Layout

A streamlined production layout ensures that materials and components flow smoothly from one process to the next with minimal handling and delay. Analyze the current layout for unnecessary movements and reorganize the space to facilitate more efficient operations. This might involve relocating equipment, creating designated areas for materials, and optimizing the workspace for easy access and movement.

The table below outlines key considerations for optimizing a production layout, the actions required to achieve this, and the benefits of reorganization.

| Consideration | Action Required | Benefits |

| Workflow Analysis | Conduct a thorough analysis of the current production process to identify bottlenecks, unnecessary movements, or delays. | Increased Efficiency: Identifies areas for improvement, leading to a more streamlined production process with fewer delays. |

| Equipment Relocation | Evaluate the placement of machinery and equipment based on the sequence of operations and move them to minimize transit time between processes. | Reduced Handling: Minimizes the time and effort required to move materials between stages, reducing the risk of damage or loss. |

| Material Access | Designate specific areas for raw materials, work-in-progress, and finished goods to reduce search and retrieval times. | Improved Organization: Enhances the visibility and accessibility of materials, reducing downtime and improving the speed of production. |

| Space Optimization | Reassess the use of space within the production area to ensure there is sufficient room for operations, storage, and employee movement. | Safer Work Environment: Creates a more organized and less cluttered workspace, reducing the risk of accidents and improving worker satisfaction. |

| Ergonomic Consideration | Arrange equipment and workstations to support ergonomic working conditions, reducing strain on workers. | Employee Well-being: Promotes a healthier work environment, leading to lower absenteeism, higher morale, and increased productivity. |

| Visual Management | Implement visual management tools, such as signage and floor markings, to indicate workflows, designated areas, and safety protocols. | Clear Communication: Enhances understanding of the production process and safety procedures, facilitating smoother operations. |

| Flexibility for Expansion | Plan the layout with flexibility in mind to accommodate future growth, new equipment, or changes in the production process. | Scalability: Allows for easy adjustments to the production layout as the business grows or evolves, minimizing future reorganization costs. |

| Technology Integration | Consider the integration of technology, such as conveyor belts or automated guided vehicles, to assist in material movement. | Automation Benefits: Leverages technology to further reduce manual handling, increase speed, and improve consistency in the production process. |

Quality Control Protocols

Implementing strict quality control protocols throughout the thread rolling process helps maintain high standards of output. Establish clear criteria for thread quality, such as dimensions, strength, and finish, and use precise measuring tools to ensure these standards are met consistently. Regular quality checks at key stages of production can identify issues early, reducing the need for rework.

Improvement Culture

Cultivating a culture of continuous improvement encourages employees to constantly seek ways to optimize production processes. Encourage feedback from operators and other staff members, who can provide valuable insights into potential improvements. Implementing a system for tracking suggestions and outcomes can motivate staff to contribute to process improvements actively.

8. Keeping Up with Industry Trends

Staying informed about the latest industry trends is vital for ensuring that your thread rolling operations remain competitive and efficient. Adapting to new technologies and methodologies can significantly enhance productivity and quality. Here are key trends to focus on:

New Technologies

Adopting new technologies is crucial for enhancing the capabilities and efficiency of thread rolling operations. Look for advancements in automation, machine learning, and precision engineering that can improve accuracy. Integrating these innovative technologies into your operations can reduce labor costs and increase production speeds, keeping your business at the forefront of the industry.

Sustainability Practices

Sustainability practices are becoming increasingly important in manufacturing. Implement measures to reduce energy consumption, recycle waste materials, and use environmentally friendly lubricants and materials. Adopting sustainable practices helps you to reduce operational costs and meet the growing demand for green manufacturing processes from customers and regulators.

Digital Transformation

The digital transformation of manufacturing processes, including thread rolling, offers opportunities for efficiency and data-driven decision-making. Invest in digital tools that provide real-time monitoring, analytics, and predictive maintenance capabilities. These technologies can predict potential failures before they occur and enhance the overall efficiency of your operations.

Dive Deeper Into Our Resources

For some insightful reads, we’ve curated a list of recommended articles just for you:

- A Comprehensive Step-by-Step Guide to Operating Thread Rolling Machines

- How To Start a Nail Manufacturing Business?

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

Maximizing the productivity of your thread rolling machine is crucial for staying competitive in today’s market. This guide has provided expert strategies to enhance performance, ensure consistent output, and keep up with industry trends.

For businesses seeking further guidance on selecting the best thread rolling machine manufacturers, Awnail is here to help. Explore more solutions and contact us to elevate your operations.