Are you maximizing the efficiency and output of your production line? Iron nail making machines, key to manufacturing sectors, are the foundation of operational success, especially in businesses where precision matters.

My expertise in the field of nail making machinery is backed by extensive experience and a great understanding of the technological and operational variations. This knowledge is crucial for businesses looking to optimize their production capabilities.

Iron nail making machines are transformative, offering unmatched speed, consistency, and cost-effectiveness in nail production.

In this guide, we will uncover the secrets of iron nail making machines, from their operational mechanics to the significant advantages they bring. You’ll learn how to select the best machine for your business, and stay informed about technological advancements.

Read on to find out the power of these machines.

1. Overview of Iron Nail Making Machines

Iron nail making machines are robust and highly efficient systems designed for the mass production of iron nails. These machines embody the perfect blend of traditional craftsmanship and modern technology, ensuring high-speed production without sacrificing quality. Their core function is to convert raw iron or steel wire into nails of various sizes, catering to a wide range of construction and manufacturing needs.

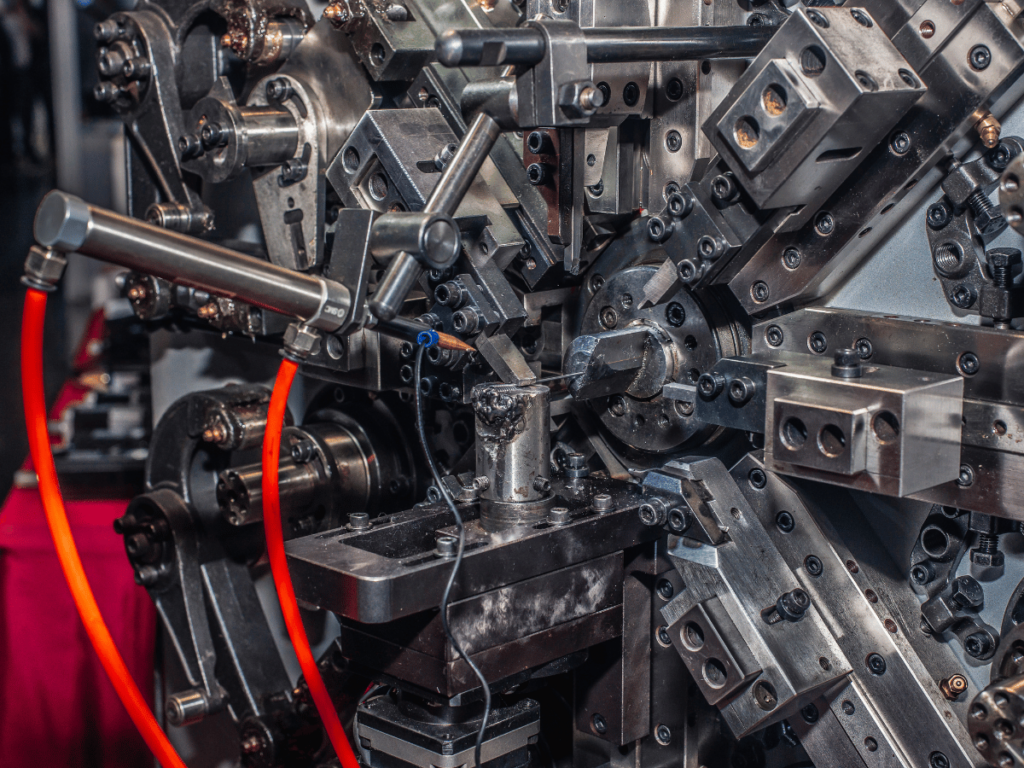

At the heart of these machines lies a precise and complex mechanism. This involves cutting the wire to length, forming the nail head, sharpening the point, and sometimes even treating the surface. The entire process is automated, allowing for consistent output and minimal material wastage. Such efficiency not only boosts productivity but also plays a significant role in reducing operational costs.

2. The Mechanics of Iron Nail Making Machines

Building on the overview of iron nail making machines, it’s clear that these machines are marvels of engineering, designed to streamline the nail production process. Here are the key mechanical components that make this possible:

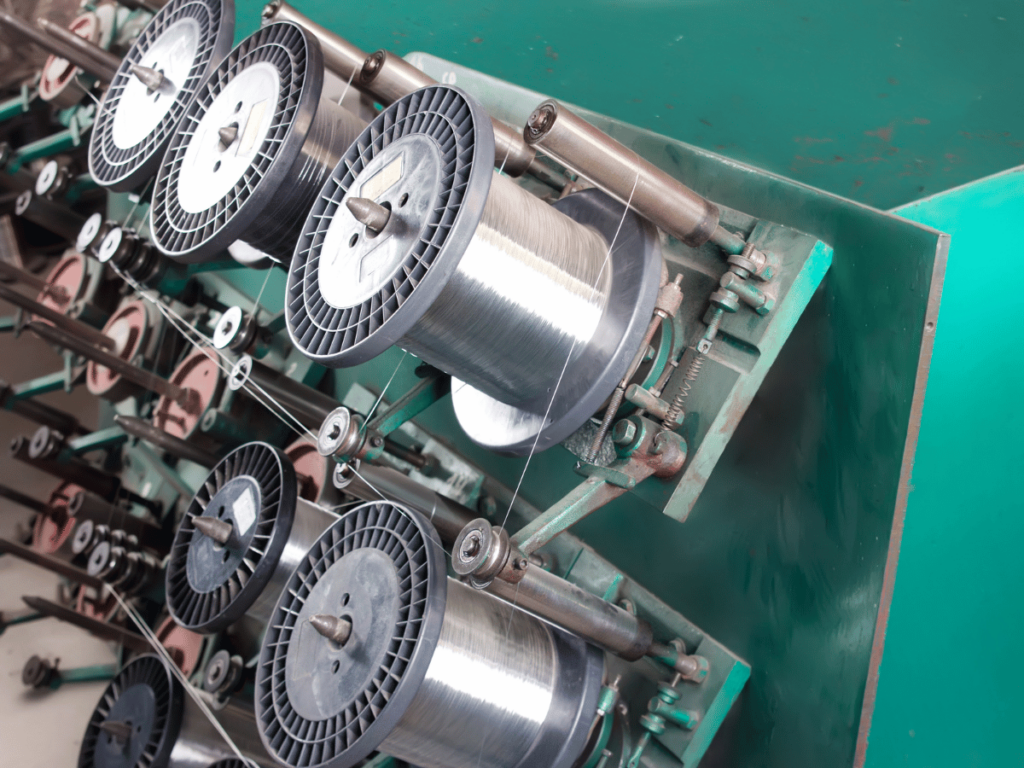

- Wire Feeding Mechanism: This is the initial stage where a continuous wire, typically made of iron or steel, is fed into the machine. The wire’s diameter corresponds to the desired nail size, ensuring precision right from the start.

- Cutting Mechanism: A cutting tool trims the wire to the predetermined nail length. This process is crucial for uniformity, as it ensures that each nail produced is of consistent size and shape.

- Head Formation: Once cut, the machine forms the head of the nail. This is achieved through a specialized die that molds the top of the wire into a flat or rounded head, depending on the nail type.

- Point Sharpening: The other end of the cut wire is then sharpened to form the nail’s point. This is done through a shaping tool which grinds the end to the desired sharpness, essential for effective nail penetration.

- Finishing and Polishing: After the nail is fully formed, some machines include a finishing stage where the nails are polished or coated. This process enhances the nail’s resistance to rust and improves its overall aesthetic.

3. The Benefits of Using Iron Nail Making Machines

Following an understanding of the mechanics behind iron nail making machines, it becomes evident how these systems offer significant advantages to businesses. Here are the key benefits of integrating these machines into your production line:

Enhanced Production Speed

Iron nail making machines like those from Awnail, dramatically increase production speed compared to manual processes. They are capable of producing thousands of nails per hour, ensuring a steady supply for large-scale projects. This speed translates into higher output, meeting market demands efficiently.

Reduced Maintenance and Downtime

Iron nail making machines are designed for durability and low maintenance requirements. Their robust construction means less frequent breakdowns and maintenance interventions, resulting in more productive hours and less downtime. This reliability is crucial for businesses that operate on tight schedules and need to avoid operational disruptions.

Flexibility in Production

Modern iron nail making machines offer flexibility in terms of nail sizes and types. Manufacturers can easily adjust settings to produce different nail sizes, catering to various market needs without requiring separate machines. For example, the same machine can be swiftly reconfigured to switch from producing small finishing nails to larger roofing nails, adapting to varying demands in the construction industry.

4. Types of Iron Nail Making Machines

Understanding the benefits of iron nail making machines naturally leads to exploring the different types available in the market. Each type is designed to meet specific production needs and scales. Here are the primary categories:

High-Speed Coil Nail Machines

High-speed coil nail machines are designed for large-scale industrial use. They excel in producing nails at an exceptionally rapid pace, suitable for projects requiring high volumes. These machines are often used in large construction and manufacturing where time and efficiency are essential. Elevate your large-scale projects with the unparalleled efficiency of high-speed coil nail machines, a game-changer in time-sensitive industries.

Wire Nail Making Machines

Wire nail making machines are versatile and widely used for a range of nail types. They can handle different wire diameters, allowing for the production of various nail sizes. This flexibility makes them suitable for businesses that produce a diverse range of nails for different applications. Awnail’s wire nail making machines exemplify this versatility, catering to businesses needing to manufacture a wide array of nail types.

Concrete Nail Making Machines

Concrete nail making machines specialize in producing nails used in concrete and masonry. These nails are typically made from harder steel and require machines that can handle the increased toughness of the material. For instance, a high-grade machine might be designed to efficiently produce thousands of galvanized concrete nails per hour, ensuring durability and strength for construction purposes.

5. Technological Advancements in Nail Making

Following the exploration of various types of iron nail making machines, it’s equally crucial to consider the technological advancements that have revolutionized this field. Here are some of these advancements in nail making:

Computerized Control Systems

Modern nail making machines are increasingly incorporating computerized control systems. These systems allow precise control over every aspect of nail production, from wire feeding to nail cutting and shaping. Computerization leads to higher accuracy, less waste, and the ability to quickly adjust settings for different nail types.

Energy Efficiency Improvements

Advancements in energy efficiency are a significant focus in the nail making industry. Newer machines are designed to consume less power while maintaining, or even increasing, output levels. This not only reduces operational costs but also aligns with global efforts to reduce industrial energy consumption and environmental impact.

Integration of Robotics

Robotics has started to play a role in nail production, particularly in the aspects of sorting and packaging. Robotic arms can now be found in some advanced nail making setups, where they pick, sort, and package nails with incredible speed and precision, further reducing labor requirements and improving overall efficiency. With the integration of robotics, precision meets efficiency, setting a new standard in nail manufacturing.

Advanced Material Handling

The latest nail making machines feature advanced material handling capabilities, ensuring that the input materials are managed more efficiently. This includes automated feeding systems that minimize material wastage and sophisticated monitoring systems that detect and correct anomalies in raw material quality, leading to a more consistent end product.

6. Applications and Uses of Iron Nails in Various Industries

The technological advancements in nail making not only enhance the production process but also expand the applications and uses of iron nails across various industries. Here are some of the areas where iron nails are extensively used:

Construction Industry

In the construction industry, iron nails are fundamental for structural integrity. They are used in framing, roofing, siding, and finishing work. Their strength and durability make them ideal for holding together materials in commercial, and industrial buildings, playing a critical role in interior and exterior applications. In my professional view, the choice of nail in construction is a cornerstone of quality and safety.

Wooden Furniture Items

With the wood furniture market expected to reach a value of $138742.19 million by 2028, as per Industry Research Co, the role of iron nails in furniture making becomes increasingly significant. They provide precision and strength in joining wood pieces, ensuring stability in various products, from robust furniture to intricate wooden crafts, aligning with the market’s growth and the diversification of consumer needs.

Manufacturing and Packaging

Iron nails are crucial in the manufacturing and packaging sectors, especially in the production of wooden crates, pallets, and other packaging materials. They provide a strong and reliable method for assembling and securing packaging, which is essential for the safe transportation of goods. From my experience, the right nail can make all the difference in these applications, significantly enhancing both durability and safety.

Here’s a table that outlines the role of iron nails in the manufacturing and packaging sectors, particularly in the context of wooden crates, pallets, and other packaging materials:

| Aspect | Description | Impact |

| Application | Used in the production of wooden crates, pallets, and other packaging materials. | Versatility: Suitable for a wide range of packaging needs. |

| Function | Provide a strong and reliable method for assembling and securing packaging. | Durability and Safety: Ensures the structural integrity of packaging, essential for the safe transportation of goods. |

| Selection Importance | The right type and size of nail are crucial for specific applications. | Optimal Performance: Enhances both the durability and safety of packaging materials, making a significant difference in their effectiveness. |

7. Challenges and Solutions in Nail Making

As we consider the extensive applications and uses of iron nails in various industries, it’s important to address the challenges faced in nail production and the corresponding solutions. Here are some common challenges and their effective solutions:

Material Wastage

In the nail making process, material wastage can be a significant issue, leading to increased costs and environmental impact. This often occurs due to inefficiencies in the production process and outdated machinery.

- Solution: Upgrading to modern machines with precise control systems can drastically reduce wastage. Implementing recycling protocols for scrap materials also contributes to a more sustainable production process.

Energy Consumption

High energy consumption is a common challenge, as traditional nail making machines can be energy-intensive. This not only increases operational costs but also contributes to a larger carbon footprint.

- Solution: Integrating energy-efficient technologies and adopting renewable energy sources can significantly lower energy consumption. Regular maintenance and optimization of machine settings also play a crucial role in reducing energy usage.

Adapting to Diverse Market Needs

The diverse needs of different markets can be challenging to meet, especially when it comes to producing a wide range of nail types and sizes efficiently. Flexibility in nail production is not just a convenience, it’s a competitive edge in today’s diverse market landscape.

- Solution: Investing in versatile nail making machines that offer easy adjustability and quick changeover times enables manufacturers to cater to varied market demands without compromising on efficiency or cost.

8. 3 Factors to Consider When Buying Iron Nail Making Machines

While understanding the challenges and solutions to nail making is crucial, it’s equally important to know what factors to consider when purchasing iron nail making machines. Here are key considerations to keep in mind:

#1 Machine Capacity and Speed

Consider the machine’s capacity to ensure it meets your production demands. A machine with a high-speed output is essential for large-scale production, but it should not compromise the quality of the nails. Assessing the balance between speed and output quality is crucial for long-term efficiency. Ensure the machine can sustain the required production rate without frequent breakdowns.

#2 Versatility and Adjustability

A versatile machine that can produce various nail sizes and types is a valuable asset. Look for machines with easy adjustability to switch between nail specifications quickly. This feature is particularly important if your market demands a range of nail types. Versatility in production prevents the need for multiple machines, saving space and resources.

#3 Durability and Maintenance

The durability of the machine affects its longevity and frequency of repairs. Choose a machine built with high-quality materials and a reputation for lasting long periods. Regular maintenance is key to preserving machine functionality, so consider the ease of maintenance and availability of spare parts. A durable machine with accessible maintenance can significantly reduce operational downtime.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

This guide has provided an in-depth look at iron nail making machines, offering valuable insights to enhance your understanding and decision-making in this crucial industry sector. Embracing this knowledge can lead to significant advancements in your business’s production capabilities and overall efficiency.

If you’re looking to delve deeper or require specific guidance on iron nail making machines, Awnail is here to assist. Contact us for expert advice and tailored solutions that align with your business objectives.