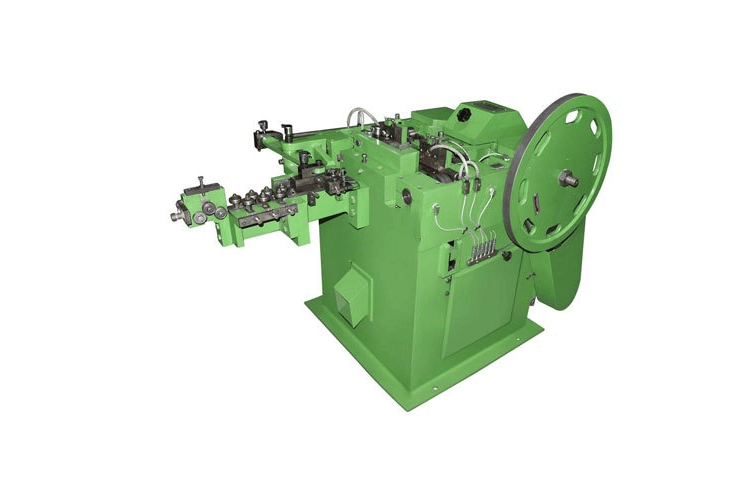

Exceptional Used Thread Rolling Machine For Your Business

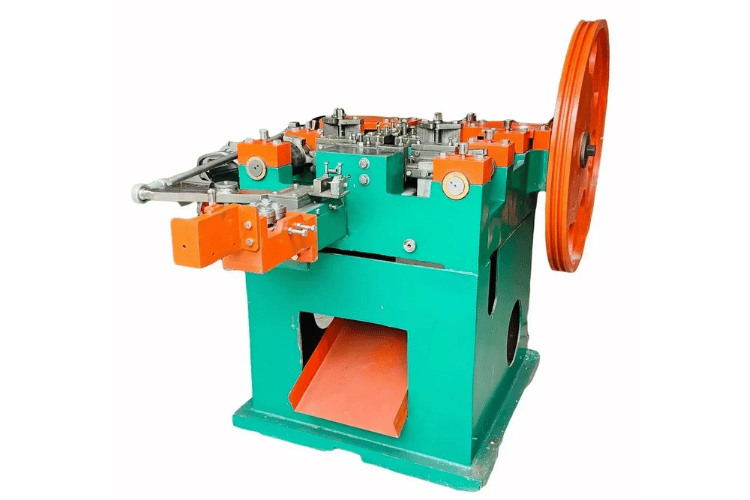

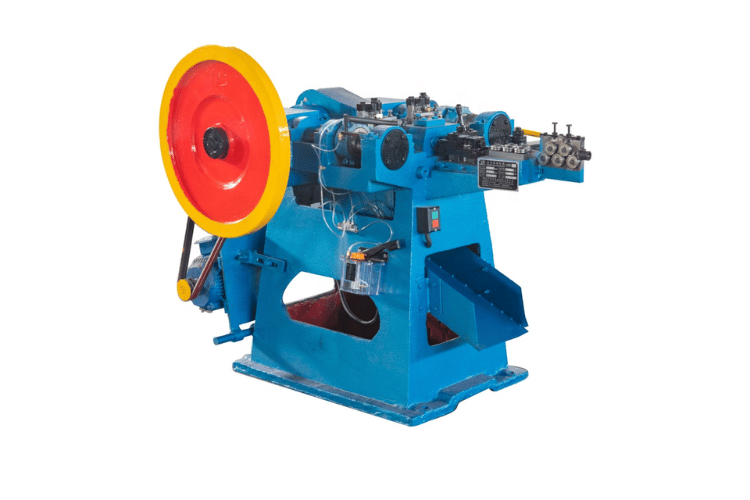

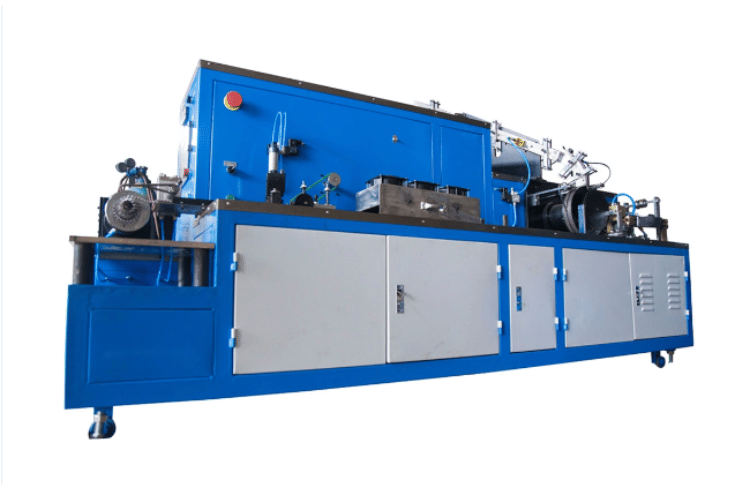

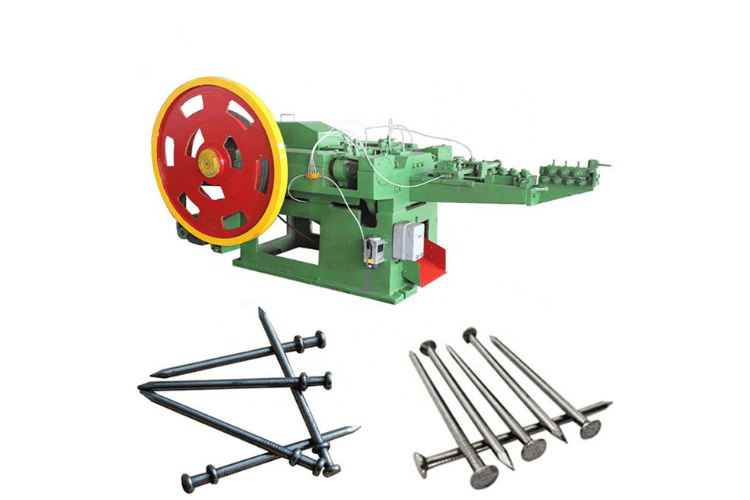

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

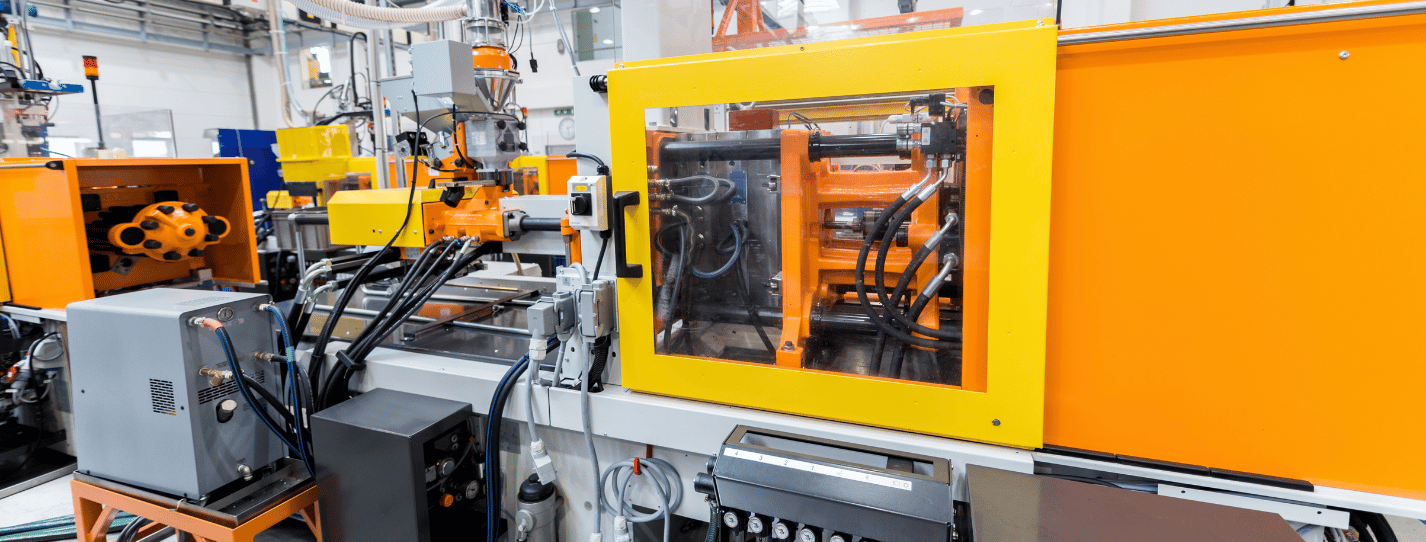

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Used Thread Rolling Machine

Our thread rolling machine is the best choice for you to make your metal nails. The machine can roll steel wire into round wire, then cut the round wire into nail length by yourself.

It can produce all kinds of nails, such as drywall screws, finish nails, and so on.

This machine is easy to operate, it only takes you a few minutes to learn how to use it.

1. Used Thread Rolling Machine Brief Explanation

A Used Thread Rolling Machine is a refurbished machine that is used to create metal or wire nails. It creates a smooth, rounded head on the nail, which makes it less likely to snag fabric or skin. The Used Thread Rolling Machine is a very common tool in the nail-making process.

It is used to create nails that are both strong and durable. When looking for a thread rolling machine secondhand, it is important to consider the size of the machine. Make sure to find one that will be able to handle the size of nails you need to create.

Also, be sure to check the condition of the Used Thread Rolling Machine before purchasing it. All of the parts must be in good working order so that you can create high-quality nails. If you are looking for a Used Thread Rolling Machine, be sure to visit your local metalworking shop or search online for a Used Thread Rolling Machine.

In most cases, you will be able to find a Used Thread Rolling Machine at a reduced price than the machines that are available in stores. Contact us at Awnail, for high-quality second-hand and refurbished thread rolling machines.

2. Used Thread Rolling Machine Key Features

A thread rolling machine is a piece of equipment that is used to create threads on metal objects. It consists of a round die that is attached to a motor, and the object that needs to be threaded is placed in the middle of the die. The die is then turned, which causes the object to be threaded.

Some key features of a thread rolling machine include:

Uniformity

The ability to create uniform threads, with different pitches, and different profiles.

Flexibility in Size and Shape

The ability to create threads in a variety of sizes and shapes.

Raw Material Range

The ability to create threads in a variety of materials. The thread roller can work with any stock of raw material.

If you are looking for a machine that can create uniform, high-quality threads, then a thread rolling machine is the perfect option. It can be used to create threads in a variety of sizes and shapes, making it an extremely versatile tool. Plus, because it is motorized, it can be operated with ease.

If you are interested in purchasing a thread rolling machine, be sure to contact us at Awnail today for more information. We would be happy to help you find the perfect machine for your needs.

3. Step by Step Guide to Use Used Thread Rolling Machine

A second-hand thread rolling machine is a great tool for producing spindle-grade screws, nails, and other construction capacity fasteners at a specific width, thread length, and speed. Here is a step-by-step guide in operating a thread roller:

Step#1 Choose the Right Size Nail

Wire nails come in different sizes, so make sure to choose the right size for your project.

Step#2 Lubricate the Die

Before using the thread rolling machine, you will need to lubricate the die with oil, coolant, or manufacturer model lubricant.

Step#3 Insert the Wire Nail into the Die

Insert the wire nail into the round die and then place it in the thread rolling machine.

Step#4 Turn on the Machine

Turn on the machine and slowly roll the wire nail through the die.

Step#4 Be Careful with the Pressure

Be careful not to apply too much pressure, or you could damage the wire nail.

Step#5 Cut off the Excess Feed

Once you have rolled the wire nail through the die, remove it from the machine and cut off any excess wire. Your wire nail is now ready to use!

Here’s a video guide on how to operate a wire thread rolling machine!

4. Benefits of Buying Used Thread Rolling Machine

There are a lot of benefits that can be gained if you buy a second-hand flat die thread roller or a thread roller for sale. Here are some of those:

Cheaper than Brand-new Machines

The main reason to buy a thread rolling machine second-hand is that they are much cheaper than new machines. Used machines are also a great option for companies that are starting up and don’t have a lot of money to spend.

Refurbished Machines are Easy to Find

Another benefit of buying a used machine is that you can often find machines that are still in good condition and have been well-maintained. This means that you can get a lot of use out of the machine without having to worry about it breaking down.

When you are shopping for a used machine, be sure to ask the seller about the condition of the machine and how often it has been used.

You also want to make sure that you know what type of dies the machine can use so that you can be sure it will work with your wire nails.

Buying a used thread rolling machine is a great way to save money and get a machine that is still in good condition.

If you are looking for a wire nail, round die, or thread rolling machine, be sure to check out the selection of used machines on our website at Awnail.

We have a wide variety of machines from top manufacturers, so you are sure to find the perfect second hand thread rolling machine for your metal nail production needs.

5. Used Thread Rolling Machine Average Price

The average price for a used thread rolling machine is around US$1,500. However, the price can vary depending on the condition of the machine and the features that it has.

6. Where to Find Used Thread Rolling Machine for Sale

There are a few places where you can find a used thread rolling machine for sale. Here are some:

Manufacturers

One option is to check with thread nail manufacturers, like Awnail. They may have equipment that they are looking to sell or they may know of someone who is selling a machine.

Online Auction Sites

Another option is to search online auction sites or classified ads websites such as Craigslist.

Machinery Dealers

You can also check with machinery dealers or metalworking suppliers in your area.

7. Precautions When Using Used Thread Rolling Machine

When using a used thread rolling machine, there are a few precautions you need to take. Here is what you need to do:

| No. | Precautions |

|---|---|

| 1 | Inspect the Machine |

| 2 | Make Sure the Die is in Good Condition |

| 3 | Lubricate the Machine Before Use |

| 4 | Never Overload the Machine |

| 5 | Steer Clear of a Working Machine |

| 6 | Always Use Safety Equipment |

| 7 | Follow the Instruction Manual |

| 8 | Familiarize Yourself with the Machine |

Inspect the Machine

Always inspect the wire nail machine for damage or bends. If the wire nail is damaged in any way, do not use the machine.

Make Sure the Die is in Good Condition

Make sure that the round die is in good condition and is properly aligned with the wire nail.

Lubricate the Machine Before Use

Make sure that the thread rolling machine is properly lubricated.

Never Overload the Machine

Never overload the machine, the maximum capacity indicated on the product manual should always be followed.

Steer Clear of a Working Machine

Keep your hands and fingers clear of the moving parts.

Always Use Safety Equipment

Always wear safety goggles and other safety equipment when using the machine.

Follow the Instruction Manual

Read and follow all safety instructions provided with the machine.

Familiarize Yourself with the Machine

Never use the machine if you are not familiar with its operation.

By following these precautions, you can safely use a used thread rolling machine.

8. How to Take Care of Used Thread Rolling Machine

Taking care of your used thread rolling machine will ensure that it will last longer and will be able to keep producing high-quality metal nails. Here are some ways to take care of your machine:

Insert the Die Properly

If you’re using a wire nail, always make sure that the round die is inserted properly. If it’s not, the wire nail might not be able to roll properly and will jam.

Remove Jammed Nails Immediately

If the wire nail is jammed, you can try to fix it by gently pushing it back down the machine with your fingers. If that doesn’t work, you might have to use a pair of pliers to get it out.

Clean the Machine After Use

When you’re finished using the thread rolling machine, make sure to clean it off with a brush or cloth. This will help prevent the buildup of dirt and rust.

If you follow these simple tips, your wire nail thread rolling machine will last for years to come!

9. 4 Tips to Consider Before Buying Used Thread Rolling Machine

When considering purchasing a used thread rolling machine, it is important to consider the following:

#1 Check the Condition of the Machine

When looking to buy a used thread rolling machine, it’s important to consider the condition of the machine, how much use it has had, and the availability of replacement parts.

#2 Consider the Compatibilities

You’ll also want to make sure that the machine is compatible with the wire size and type you need.

#3 Ask Questions

Before making a purchase, be sure to ask the seller any questions you have about the machine, and to get a demo of how it works.

#4 Have an Expert Look at the Machine

It’s also a good idea to have an expert look at the machine before buying it to make sure it’s in good working order.

Contact us at Awnail, if you have further questions about buying a second-hand or refurbished thread roller machine. Our agents are available to assist you.

10. Conclusion

Our thread rolling machine is perfect for both personal and professional use. It is sure to provide you with a high-quality experience.

This machine is easy to operate and only takes a few minutes to learn how to use it. You will be able to quickly and easily roll your metal nails with this machine.

Purchase the thread rolling machine today on our website at Awnail!

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us