Exceptional Nail Packing Machine For Your Business

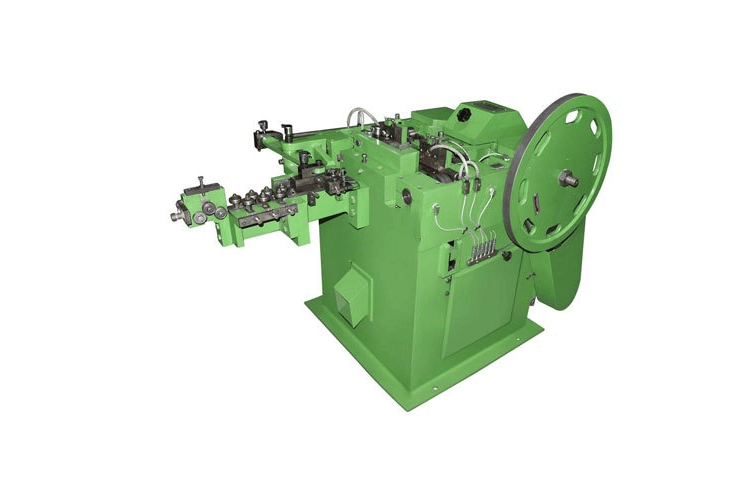

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

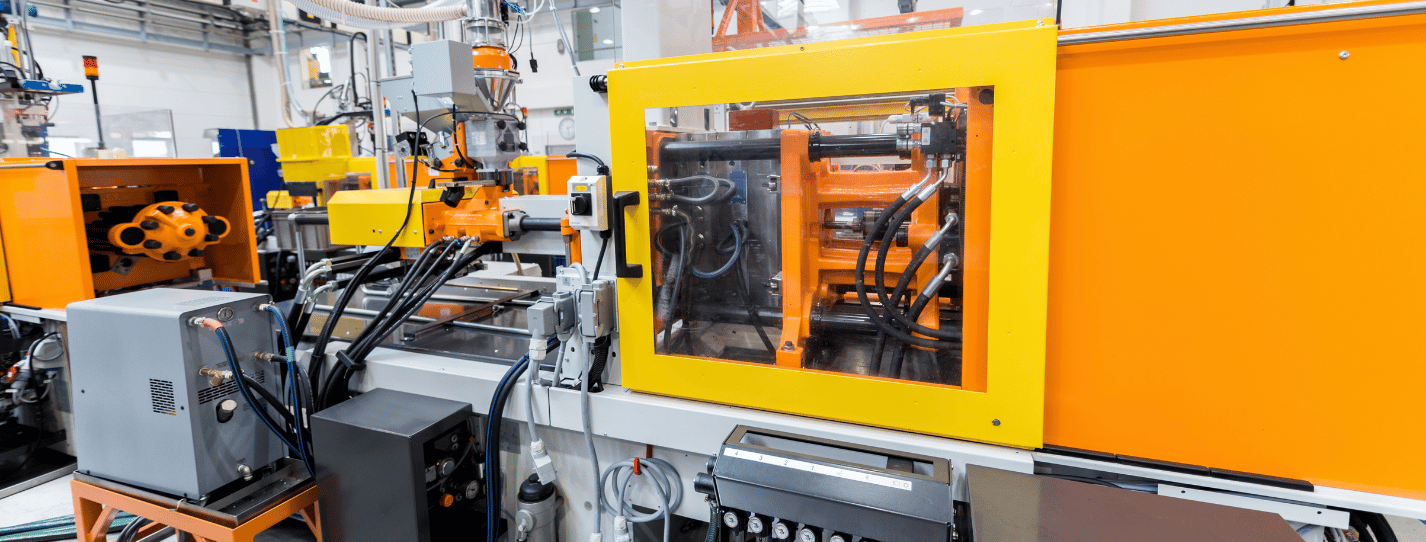

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

How to Choose the Best Nail Packing Machine for Your Business

Nail packing machines are an essential tool for most nail businesses. But with so many different models and brands on the market, it can be difficult to know which machine is right for your business.

Choosing the best nail packing machine for your business depends on several factors you need to take into consideration like the different features to look for – shapes and sizes, the machine capacity, and its price.

In this blog post, we’ll explore some of the factors you should consider when choosing a nail packing machine, as well as give you some recommendations for models that are perfect for small businesses. Let’s get started!

1. How to Choose the Best Nail Packing Machine for Your Business?

When it comes to nail packing machines, there are a few factors you’ll want to consider before making a purchase. Here are some factors on how to choose the best machine for your business:

Type of Nails

There are two main types of nails. Make sure the machine you choose can package both types of nails.

Size of the Nails

Nail sizes vary, so make sure the machine you choose can package nails of different sizes.

Speed of the Machine

Nail packing machines come at different speeds, so make sure you choose one that is appropriate for your business.

Price

Nail packing machines come in a wide range of prices. Make sure you choose one that is within your budget but still meets all your requirements.

If you’re still not sure which machine is right for you, contact the experts at Awnail. They can help you find the perfect machine for your business and answer any questions you have about nail packing machines.

2. Nail Packing Machine Definition and How It Works

A nail packing machine is a device that is used to pack nails into a container. The nails are placed into the machine and then the machine will pack them tightly into the container.

This machine is beneficial because it can help to ensure that the nails are packed tightly and will not fall out of the container. Nail packing machines are used in many different industries, including construction and manufacturing.

Nail packing machines are designed to work with different types of nails, including galvanized, stainless steel, and plated nails. Nails can also be packed into other containers such as plastic bags or cardboard boxes using this type of equipment.

The Nail Packing Machine has two main parts:

- Hopper

- Piston

#1 The nails are placed into the hopper and then they fall into a chamber that is located beneath the piston.

#2 When the piston is activated, it will push down on the nails and force them into the container.

#3 Lastly, it ensures that all of the air is removed from the inside of the container and that the nails are tightly packed.

3. Nail Packing Machine Key Features

When it comes to nail packing machines, there are a few key features that make them a great choice for your business. Some of these features include:

User-friendly Interface

One of the key features of the nail packing machine is its user-friendly interface. This means that it is easy to use, even for those who are not familiar with such machines.

Fast and Easy Setup

Another key feature of the nail packing machine is its fast and easy setup. This means that you can have it up and running in no time, without having to go through a lot of hassle. This makes it a great choice for businesses that want to get started quickly and without any delays.

Compact Design

Another key feature of the nail packing machine is its compact design. This means that it takes up less space than other machines, making it a great choice for businesses that want to save on storage space.

Durable Construction

Another key feature of the wire nails packing machine is its durable construction. This means that it is built to last, making it a great choice for businesses that want a machine that will stand the test of time.

These are just a few of the key features that make the nail packaging machine a great choice for your business. Be sure to research all of the different options available to find the best machine for your needs.

4. Parts & Construction of a Nail Packing Machine

The nail packing machine has several parts and these parts include the following:

Nail Feeder

This part of the machine feeds nails into the packaging area. Nails are placed into the feeder and then they fall into a chamber that is located beneath the piston.

When the piston is activated, it will push down on the nails and force them into the container. Lastly, it ensures that all of the air is removed from the inside of the container and that the nails are tightly packed.

Nail Pusher

The nail pusher is responsible for pushing the nails through the packaging material. This ensures that they are tightly packed and will not fall out of the container.

Packaging Area

The packaging area is where the nails are packaged into bags or boxes. This area is typically controlled by a nail pusher, which ensures that the nails are tightly packed and will not fall out of the container.

Sealing Area

This is where the package is sealed shut. This ensures that the nails are tightly packed and will not fall out of the container. Nail pushers come in a variety of different sizes, so be sure to select the right one for your machine.

Cutting Area

Extra packaging material is cut away from the nails in this step. This makes sure that the nails don’t fall out of the container.

The construction of a nail packing machine is an important process that needs to be done correctly to ensure the machine functions properly. The following are the steps that are involved in the construction of a nail packing machine:

#1 Fabricate the frame of the nail packing machine.

#2 Assemble the frame.

#3 Install the drive system.

#4 Install the electrical system.

#5 Install the pneumatic system.

#6 Final assembly and testing of the nail packing machine.

Each of these steps is important in the construction of a nail packing machine and must be done correctly for the machine to function properly. If you are unsure of how to construct a nail packing machine, it is best to consult with a professional like Awnail as they can help you get the job done right.

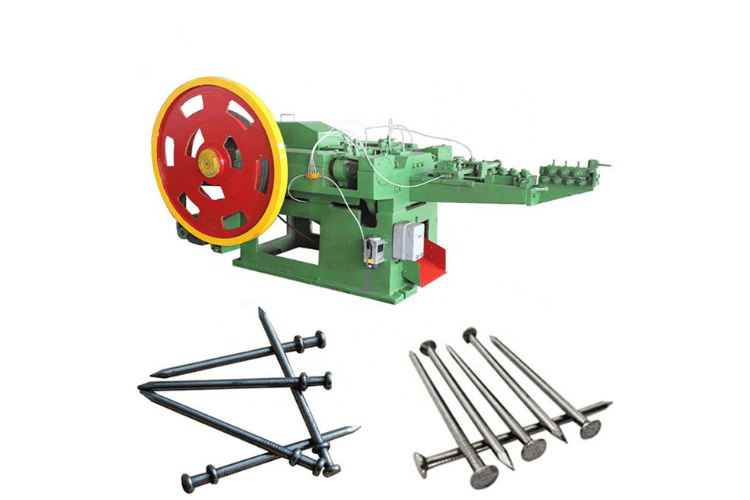

5. Different Types of Nail Packing Machine

Nail packing machines come in a variety of types and sizes, but all serve the same general purpose: to pack nails into boxes or other containers. Some of the most common types include the following:

Manual Nail Packing Machine

This type is operated by hand and is often used for small batches of nails. It is simple to use and can be operated by just about anyone. If you’re looking for a simple, low-cost option, the manual machine might be right for you.

Semi-automatic Nail Packing Machine

This type is semi-automatic, meaning that it requires some manual labor but also has some automated features. It is often used for medium to large batches of nails.

Automatic Nail Packing Machine

This type is fully automatic, meaning that it requires no manual labor. It is often used for large batches of nails and can speed up the packaging process significantly. If you need to pack nails in large quantities quickly and easily, the automatic machine is the best option.

Which type of nail packing machine you choose will largely depend on your needs and preferences. Contact us at Awnail to learn more about the different types of nail packing machines available and find the one that’s right for you.

6. Step by Step Guide to Use Nail Packing Machine

Nail packing machines are used to pack nails into small boxes or bags. It is an important piece of equipment in any construction or hardware store. Here is a step-by-step guide on how to use a nail packing machine:

| No. | Steps |

|---|---|

| 1 | Turn on the Machine |

| 2 | Load the Nails Into the Machine |

| 3 | Close the Lid for Packing |

| 4 | Open the Lid Once the Nails Are Packed |

| 5 | Unplug the Machine |

Step #1 Turn on the Machine

Plug the machine and turn it on. The machine will warm up for a few minutes. Once it’s warmed up, you can start packing nails.

Step #2 Load the Nails Into the Machine

The nails will go into a small hopper at the top of the machine. You can either use your hand to put them in or use a small scoop.

Step #3 Close the Lid for Packing

Once the nails are in the hopper, they will automatically be packed into the box or bag. Make sure that there is enough space in the box or bag for the nails to move around. If there isn’t, then you’ll need to adjust the machine accordingly.

Step #4 Open the Lid Once the Nails Are Packed

Once the nails are packed, open the lid and remove the finished product. If any nails are not in a perfect square or rectangle, you can fix them by hand. Nail packing machines are a great way to pack nails quickly and efficiently.

Step #5 Unplug the Machine

Unplug the machine and let it cool down. Make sure to read the instructions carefully before using the machine.

Here’s a video of how a nail packing machine works!

7. Benefits of Using Nail Packing Machine

A nail packing machine is a very important tool in the manufacturing process of nails. It helps to speed up the process and ensure that the nails are all of uniform size and shape.

In addition, a nail packing machine can also help to improve the quality of the nails. Some of the benefits of using a nail packing machine include:

Improved Quality

The nails will be more uniform in size and shape, which will result in a higher quality product.

Increased Speed and Efficiency

A nail packing machine can greatly increase the speed and efficiency at which nails are packed. This can save time and labor, which can be very beneficial for businesses.

Precise Packaging

A nail packing machine ensures that nails are packed in an orderly and precise manner, which can help to improve the overall appearance of the product.

Accurate Weights

Nail Packing Machines can also ensure accurate weights for nails, which can help to maintain quality control.

Reduced Labor Cost

The use of a nail packing machine can help to reduce the need for labor, which will result in lower production costs.

In conclusion, the benefits of using a nail packing machine are clear. It can help to improve the quality and speed of production, while also reducing labor costs.

If you are looking for a way to improve your nail manufacturing process, then a nail packing machine is the answer.

8. Where to Find Wholesale Nail Packing Machine Manufacturers

When it comes to finding reliable and quality nail packing machine manufacturers, it can be a daunting task. However, with the right research and by following some simple guidelines, you should be able to find a supplier that meets your needs.

Here are some tips on where to find wholesale nail packing machine manufacturers:

Online Directories

Many online directories list suppliers of various products and services, including nail packing machines. A quick Google search will turn up several results. Be sure to review the list of suppliers carefully and compare pricing and other factors before making a decision.

Trade Shows

Trade shows are a great place to find reliable suppliers of all kinds of products, including nail packing machines. Attending a trade show can allow you to meet with manufacturers and get a feel for their products and services.

Referrals

Ask your friends and colleagues if they know of any reliable suppliers of nail packing machines. Chances are, someone you know has had a similar need in the past and can recommend a good supplier.

Local Chamber of Commerce

Another option is to contact your local Chamber of Commerce. They will likely be able to provide you with a list of reputable companies that offer wholesale nail packing machines.

By following these tips, you should be able to find a quality supplier of nail packing machines that meets your needs and budget.

9. Average Cost of a Nail Packing Machine

The average cost of a nail packing machine is around $9,000. Nail packing machines are used to pack nails in boxes for shipping. They are typically made of stainless steel and have a capacity of up to 2,000 nails per minute.

Nail packing machines can be used for both flat and round nails, and come in a variety of sizes to accommodate different production needs. When shopping for a nail packing machine, it is important to consider the size and capacity of the machine, as well as the type of nails it can pack.

Machines that can pack both flat and round nails are typically more expensive than those that can only pack one type of nail. It is also important to ensure that the machine can meet the production needs of your business.

If you are looking for a nail packing machine that is affordable and meets your production needs, be sure to check out the selection available at Awnail.

10. 3 Things to Consider When Choosing a Nail Packing Machine

There are a few factors that you should consider when choosing a nail packing machine.

#1 Type of Nails

The most important factor is the type of nails that the machine can pack. Make sure to choose a machine that can pack the type of nails that you use.

#2 Size of Machine

Another factor to consider is the size of the machine. Make sure to choose a machine that is the right size for your needs. If you plan on packing nails in bulk, make sure to choose a machine that is large enough to accommodate your needs.

#3 Price of Machine

Finally, you should consider the price of the machine. Make sure to choose a machine that fits within your budget.

11. Conclusion

A nail packing machine should be chosen after taking into account what kind of nails will be used, what size business you run, and how often the machine will be used. We have talked about the different things you need to think about when you choose a nail packing machine.

If you are unsure about which machine is the best, our team at Awnail can help! We have years of experience in the industry and can assist you in finding the perfect machine for your needs. Contact us if you have any questions or want more information about our products!

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us