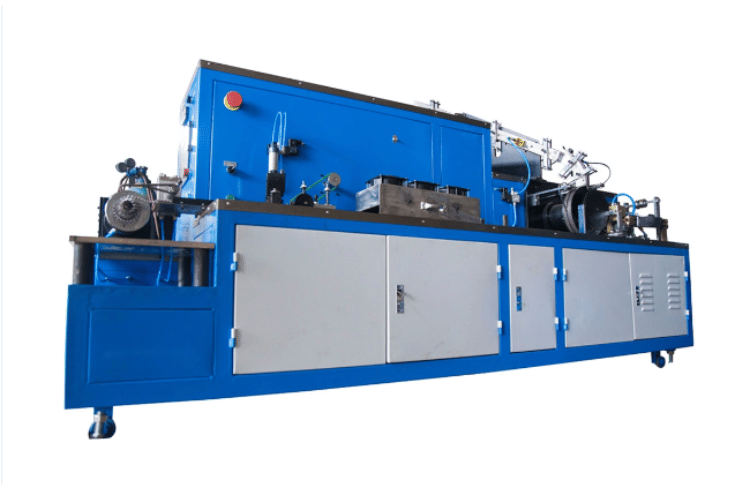

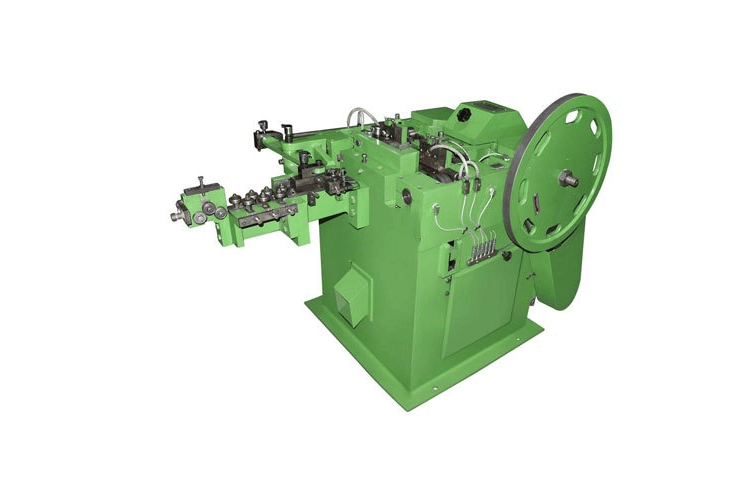

Exceptional Used Wire Drawing Machine For Your Business

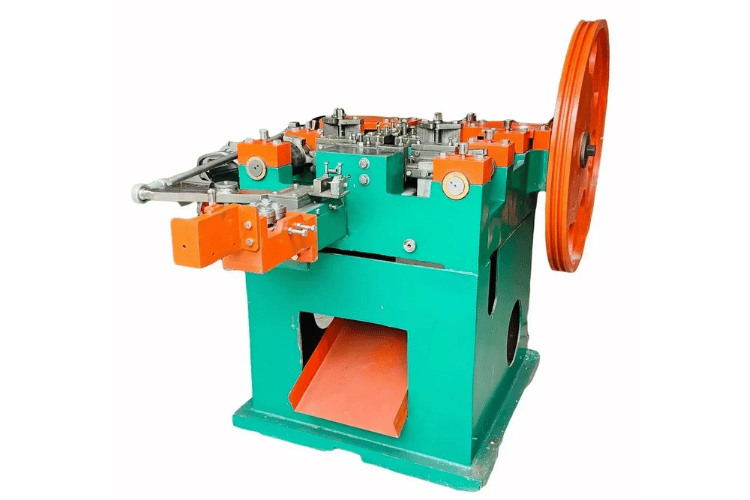

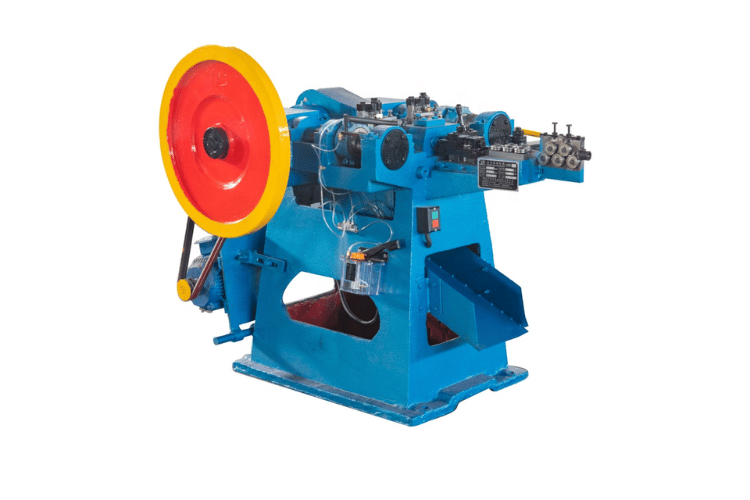

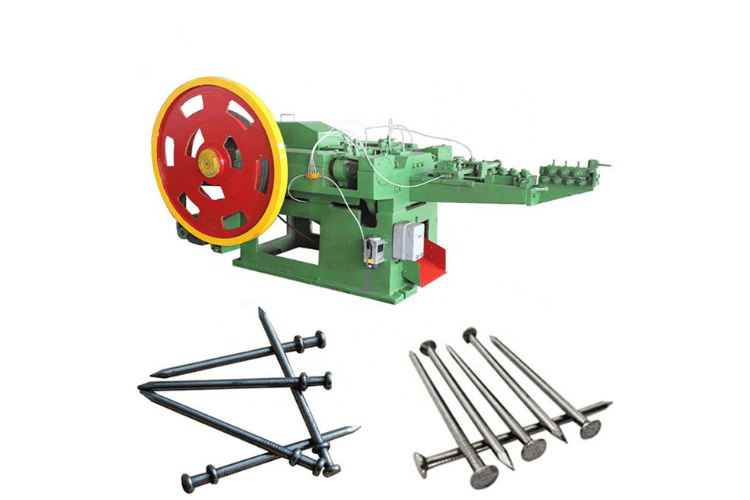

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

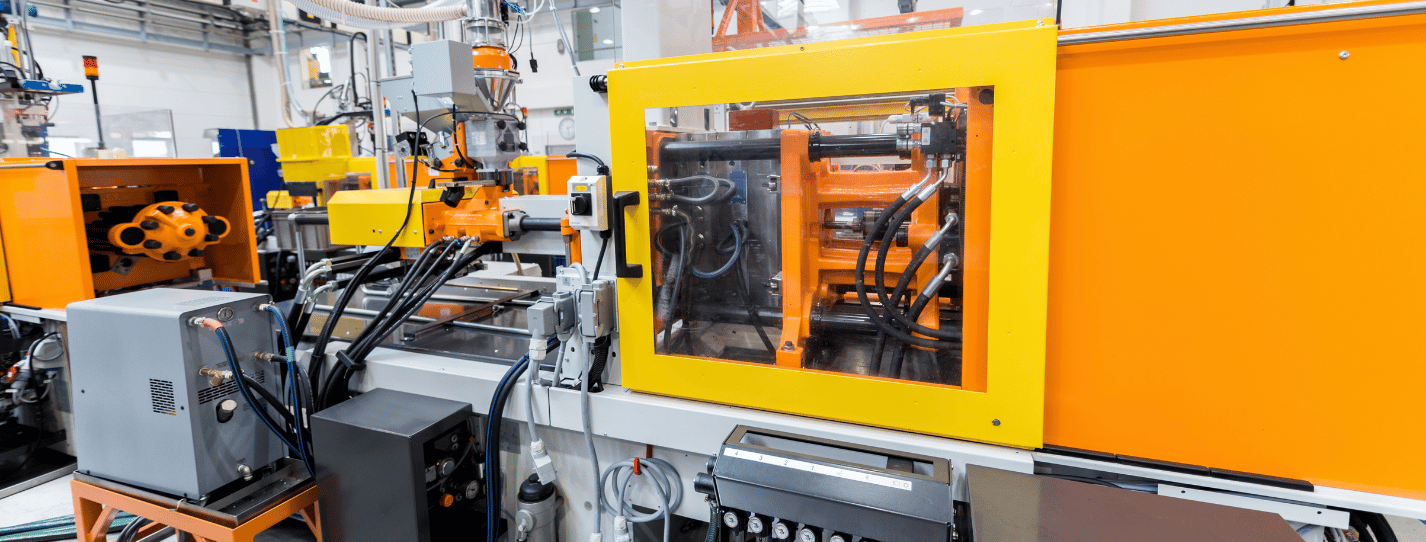

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Buying Used Wire Drawing Machine – What You Need to Know

When it comes to wire drawing machines, there are a lot of different factors to consider. Not only do you need to think about the size and type of machine you need, but you also need to find one that is within your budget.

In this blog post, we will discuss some of the things you need to keep in mind when buying a used wire drawing machine.

So, if you’re in the market for one, keep reading!

1. What Is a Wire Drawing Machine

A wire drawing machine is used to form a wire or tube into the desired shape and size. Typically, the wire will begin as round and progress through smaller dies until it reaches the desired form or thickness. It can be used for many different applications, including cable manufacturing, copper production lines, and aluminum extrusion processes.

Multiple die sets are used in some wire drawing machines, allowing them to draw wire at different speeds and sizes at the same time. Other wire drawing machines provide operators more control over the operation by allowing them to make changes as needed throughout production runs.

Wire drawing machines are also noted for their precision and consistency in producing wire.

2. Different Types of Wire Drawing Machines Available on the Market

There are a few different types of wire drawing machines available on the market, and each has its own set of benefits:

Continuous Wire Drawing Machine

A continuous wire drawing machine is used to produce long lengths of wire. This type of machine is ideal for high-volume production runs.

Drawbench Wire Drawing Machine

A drawbench wire drawing machine is used to draw wire at a slower rate than the continuous type of machine. A drawbench has two or more dies on it and produces equal amounts of the finished product during each pass through the die set.

Multi-Die Wire Drawing Machine

With multi-die machines, you can produce different sizes and shapes at once with just one machine. This type of machine is ideal for manufacturers who need to produce a variety of wire products.

Tube Drawing Machine

A tube drawing machine is used to draw tubes or rods instead of wires. It works in the same way as a wire drawing machine, but the dies are much larger.

Bar Drawing Machine

This wire drawing machine will produce wire that is thinner than the wire produced by a die drawing machine. The wire passes through bars with smaller holes until it reaches the desired size or thickness.

Any type of used wire drawing plant for sale can be found on used equipment marketplace websites and equipment auction sites.

3. Benefits of Buying a Used Wire Drawing Machine

Here are some of the benefits of used wire drawing equipment, which is why they remain one of the most popular ways to draw wire.

Cost-Effective

A used wire drawing machine for sale can be a cost-effective way to get started in the wire drawing business. You can find used drawing machines for sale at a fraction of the price of new machines.

Ease of Use

Used wire drawing equipment is often very easy to set up and use, making them a good choice for beginners.

Precision and Consistency

Wire drawing machines are known for their precision and consistency in producing wire. This makes them a good choice for manufacturers who need to produce high-quality wire products.

Wide Range of Applications

Wire drawing machines can be used for many different applications, including cable manufacturing, copper production lines, and aluminum extrusion processes. They are used in the production of a wide variety of wire products, including jewelry and medical devices.

There are many used wire drawing machine suppliers who can help you find the right used wire drawing equipment for your needs. They will be able to provide you with information on their inventory and wire drawing machine for sale so that you can make an informed decision about which machine is best for your business.

4. Things You Need To Consider Before Buying a Used Wire Drawing Machine

When buying used wire drawing machines, it is important to be aware of their condition and the potential repairs that may be necessary. It is also important to understand the specific needs of your business to choose the right machine.

Here are some factors to consider when buying used wire drawing machines:

Type of Wire

Each type of wire drawing machine is used for a specific type of wire. Make sure you select the machine that is best suited for your needs.

Wire Drawing Machine Manufacturer

Not all wire drawing machines are created equal. It is important to select a machine from a reputable manufacturer.

Wire Drawing Machine Size

The size of used wire drawing machines can vary greatly, depending on the type and model used. Make sure you select a machine that is large enough to meet your needs but not too big for the space available in your facility.

Wire Drawing Machine Condition

Be sure to inspect used wire drawing machines carefully before making a purchase. Look for signs of wear and damage that may require repairs.

Wire Drawing Machine Price

Used wire drawing machines can be found at a variety of price points, depending on the make and model. Be sure to compare prices before making a purchase.

Wire Drawing Machine Warranty

Some used wire drawing machines may come with a limited warranty. Be sure to ask about the terms and conditions of any warranties that are offered when making your purchase.

Wire Drawing Machine Repair

Repairs may be necessary with used wire drawing machines. Ask about the availability of repair parts before making a purchase.

5. Where Can You Find Used Wire Drawing Machines for Sale

Used wire drawing machine for sale can be found at:

- Wire drawing machine suppliers and manufacturers such as Awnail

- Machinery dealers

- Industrial equipment auctions

- Machinery brokers

- Used equipment forums and websites

6. Price Range of Used Wire Drawing Machine

The cost of used wire drawing machines depends on several factors, including:

- Type and size used

- Condition used in (new or used)

- Manufacturer and model used

- Repair costs and availability of spare parts used in.

The price range of used wire drawing machines varies from $50,000 to more than $200,000 for a new machine with all the features you need. If you are looking for wire drawing machines for sale that will meet your needs without breaking the bank, consider buying a used wire drawing machine.

7. 6 Steps on How To Set Up and Use a Wire Drawing Machine Safely

Setting up and using a wire drawing machine is not as complicated as it may seem, but there are a few things you need to do to ensure safe operation. Here are 6 steps on how to set up and use a wire drawing machine safely:

Step #1 Read the Operator’s Manual

Before using a wire drawing machine, be sure to read the operator’s manual. This will ensure that you understand how to safely set up and use the machine.

Step #2 Set the Machine Up in a Safe Location

Make sure there is ample room for the wire drawing machine to operate safely. If possible, set it up on a flat surface with adequate lighting and ventilation.

Step #3 Wear Safety Equipment

When using used wire drawing machines, be sure to wear appropriate safety equipment at all times. This includes ear protection, gloves, and safety glasses.

Step #4 Check the Machine for Damage or Wear

Before using used wire drawing machines to draw wires, check them carefully for signs of damage or wear. Make sure that all parts are in good working order and replace any worn or damaged components before use.

Step #5 Start Drawing Wires Slowly

When starting to use used wire drawing machines, begin by drawing wires slowly. This will help you get used to the machine and identify any potential problems.

Step #6 Stop Using the Machine if There is a Problem

If you encounter a problem while using used wire drawing machines, stop using the machine immediately and consult with your supplier or manufacturer. Do not try to fix the machine yourself.

By following these safety guidelines, you can use used wire drawing machines safely and efficiently.

Here’s a video of how wire drawing machines work!

8. 9 Tips for Maintaining Your Wire Drawing Machine

Maintaining a wire drawing machine can be a challenge, especially if you are used to using older models. Here is an overview of some tips for maintaining your wire drawing machine!

| No. | Tips |

|---|---|

| 1 | Keep the Wire Drawing Machine Clean |

| 2 | Use the Correct Lubrication System for Your Wire Diameter |

| 3 | Keep the Quench Tank Full |

| 4 | Check the Wire Guide for Wear and Tear |

| 5 | Keep the Die Plate and Wire Guide Clean |

| 6 | Replace the Wire Guide as Needed |

| 7 | Keep the Die Plate and Wire Guide Lubricated |

| 8 | Check the Quench Tank for Debris |

| 9 | Check the Wire Drawing Machine for Proper Operation |

#1 Keep the Wire Drawing Machine Clean

It is important to keep the wire drawing machine clean to ensure optimal performance. Dust and debris can build up on the die plate, in the quench tank, and around the wire guide, which can cause problems with wire quality and speed.

#2 Use the Correct Lubrication System for Your Wire Diameter

If you are using a wire drawing machine to draw wire with a diameter larger than .020″, it is important to use a lubrication system. The wrong type of lubrication can cause damage to the wire and the wire drawing machine.

#3 Keep the Quench Tank Full

The quench tank should be kept full of water or oil to help cool the wire after it has been drawn through the wire drawing machine.

#4 Check the Wire Guide for Wear and Tear

The wire guide is a critical component of the wire drawing machine. It is important to check it regularly for wear and tear and replace it as needed.

#5 Keep the Die Plate and Wire Guide Clean

The die plate and wire guide should be cleaned regularly to ensure optimal wire quality. They can become dirty with dust and debris over time, which can cause problems with wire speed and quality.

#6 Replace the Wire Guide as Needed

It is important to check the wire guide for wear & tear regularly. If it is found to be worn, it should be replaced immediately.

#7 Keep the Die Plate and Wire Guide Lubricated

The die plate and wire guide should be lubricated regularly with a light coating of oil or grease. This will help to reduce friction and increase wire speed.

#8 Check the Quench Tank for Debris

The quench tank should be checked regularly for debris and cleaned as needed. Debris can cause problems with wire quality and speed.

#9 Check the Wire Drawing Machine for Proper Operation

It is important to check the wire drawing machine for proper operation regularly. If there are any problems, troubleshoot and fix them as soon as possible.

Wire drawing machines are an essential piece of equipment for wire manufacturers. By following the maintenance and troubleshooting tips listed above, you can help ensure that your wire drawing machine operates at its optimal level.

9. How To Inspect and Test a Used Wire Drawing Machine

If you find used drawing machines for sale you should inspect the equipment for the following:

Machine Should Be in Good Physical Condition

The machine should be free of physical damage and all parts should be in good working order.

Parts Should Be Intact

All parts of the machine should be present and in good working order. Missing or broken parts can indicate that the machine has been used extensively and may not be reliable.

Check the Condition of Parts

Rusty or damaged hardware can cause problems with the equipment and may need to be replaced. You should also check for loose wires and cables as these can indicate that the machine has been used extensively and is not reliableTest the Machine for Proper Operation

Once you have inspected the machine, it is important to test it for proper operation. Start by running a short piece of wire through the machine and checking for quality and speed. If there are any problems, troubleshoot and fix them as soon as possible.

Machine Should Be Under Warranty Period

If the used drawing machine is under warranty period, you should check the terms and conditions of coverage. If there are any problems during this time, contact the manufacturer or service center for assistance.

If the used wire drawing machine passes all the inspections, then it is probably a good buy and can use it safely and effectively. Remember to get a warranty for it just in case something does go wrong.

10. Conclusion

Buying used wire drawing machines can be a cost-effective way to get started in the wire drawing business. It is important to know what factors to consider when making your purchase, where you can find used wire drawing machines for sale, and the benefits of purchasing used instead of new.

If you need help figuring out which one will work best for your needs, feel free to contact us at Awnail.

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us