Exceptional Nail Making Machines For Your Business

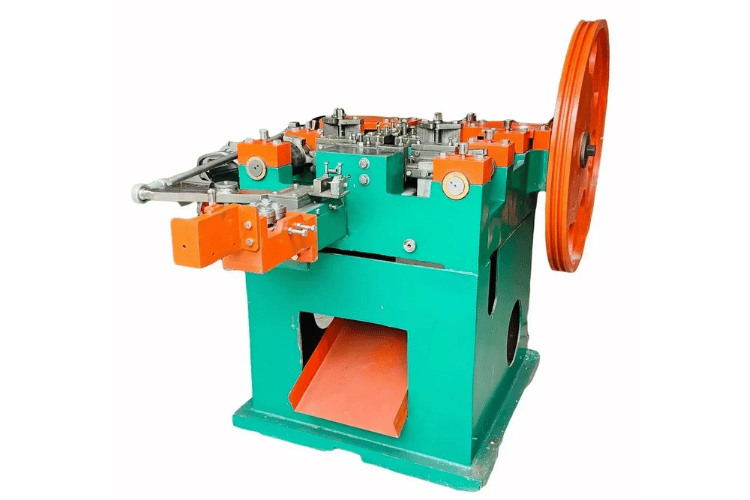

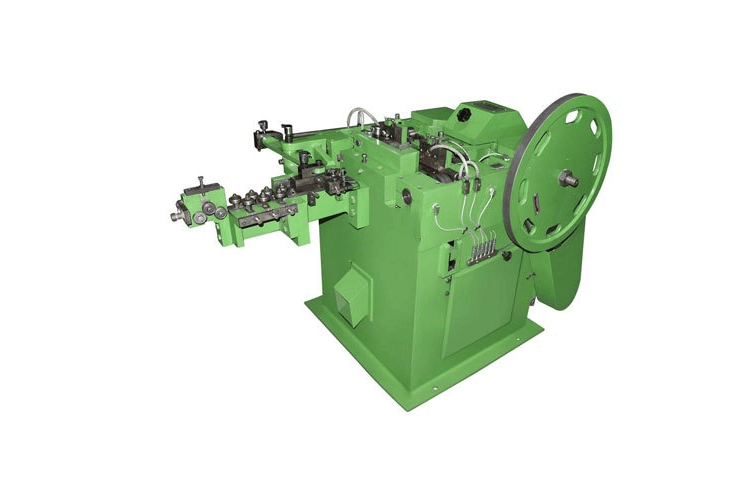

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

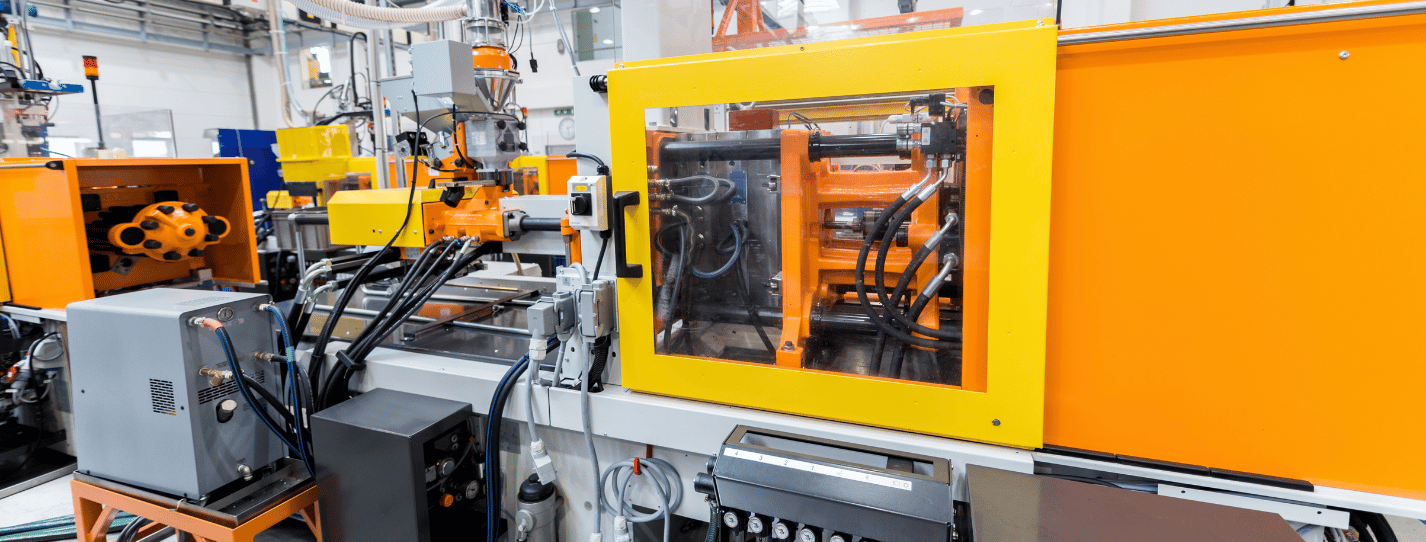

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Features and Benefits of Nail-Making Machine

Features of Nail-Making Machine

Precision Cutting Mechanism

Advanced Technology Integration

Enhanced Quality Control

Benefits of Nail-Making Machine

Increased Productivity

Cost-Efficiency

Market Versatility

Applications of Nail-Making Machine

Construction Industry

Furniture Manufacturing

Pallet and Crating Industry

3 Considerations When Buying Nail Making Machine

#1 Machine Capacity

#2 Grade 304 Stainless Steel Construction

#3 High-Strength Materials and Robust Construction

Dive Deeper Into Our Resources

Nail Making Machine Features

Geographical Focus

Starting and Managing a Nail Manufacturing Business

- How To Start A Nail Manufacturing Business

- Exploring the Nail Making Machine Industry’s Landscape

- Exporting Nail Making Machines: A Step-by-Step Journey

- A Complete Guide to Safety Certifications for Nail Making Machines

- Innovation in Nails: The Impact of High-Speed Manufacturing

Nail Making Machine Insights and Reviews

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- A Comprehensive Buyer’s Guide to Nail Making Machines

- 2024’s Best Nail Making Machines: Top 10 Picks Reviewed

- Customer Reviews: Insights into the Latest Nail Making Machines

- Expert Analysis: Rating the Top Nail Making Machines in the Industry

Operational Guides and Technological Advances

- How Nails Are Manufactured from Start to Finish

- 8 Steps to Operating Your Nail Making Machine Efficiently

- The Future of Nail Making: Innovations Transforming the Industry

- Diverse Applications of Nail Making Machines in Various Industries

- A Buyer’s Guide to Used Nail Making Machines

Industry Events and Expos

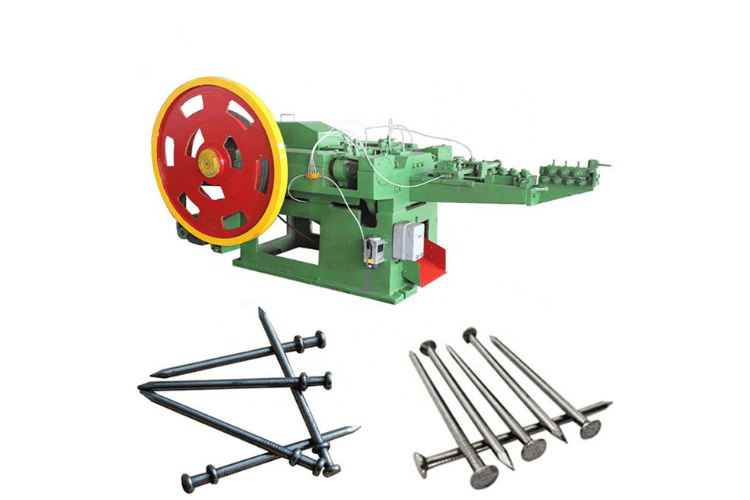

Nail Making Machine: The Best Way to Make Nails

Nails are an important part of construction, furniture-making, and many other industries. If you need nails, you need a nail-making machine. Nail-making machines come in a variety of types and sizes, so it’s important to choose the right one for your needs.

In this blog post, we’ll discuss the different types of nail-making machines and help you decide which is best for your business. Stay tuned!

1. What Is a Nail-Making Machine

A nail-making machine is a device used to form nails out of metal wire. The nail-making process starts by feeding wire into the nail-making machine. The machine will then cut the wire to the desired length and shape it into a nail.

The nail is then passed through a series of rollers that give it its final shape and polish it. Finally, the nail is ejected from the machine and ready for use.

Nail-making machines come in a variety of sizes and can be used to make nails of different sizes and shapes.

They are commonly used in nail manufacturing plants, but they can also be found in small-scale workshops. If you’re looking for a quality nail-making machine, be sure to shop around and compare prices. You can find nail-making machines for sale online or in specialty stores.

With the right machine, you can easily produce high-quality nails at a fraction of the cost of buying them from a store. Contact us at Awnail, invest in a nail-making machine today, and start producing your nails!

2. How Does a Nail-Making Machine Work

The nail-making machine can be used to create nails in a variety of sizes and shapes. This makes it a versatile tool for many different applications. The nail-making equipment is also relatively easy to operate, which makes it a popular choice for small businesses and home users.

Nail-making machines are used to create nails from metal wire. Here’s how to nail making machine works:

Feeding the Metal Wire into the Machine

The nail-making process begins by feeding a metal wire into the nail-making machine.

Cut the Wire

This wire is then cut to the desired length, and a point is formed at one end.

Extrude the Nail

The nail is then given its final shape by a series of dies.

Polishing the Nail

Finally, the nail is polished and packaged for sale.

Here’s a video of the manufacturing process of steel nails!

3. Benefits of Using a Nail-Making Machine

There are several reasons why you might want to use a nail-making machine. Here are some of those:

Efficiency

There are many benefits to using a nail-making machine. Perhaps the most obvious benefit is that it can help you to produce nails more quickly and efficiently than if you were using manual methods.

This can save you time and money, as it can reduce the amount of labor required to make nails.

Nail-making machines are efficient and can produce a large number of nails in a short amount of time.

They also produce nails that are of a high quality, which is important for both professional and DIY users. A nail manufacturing machine is also a great choice for businesses that need to produce nails in large quantities.

Consistency

Another advantage of using a nail plant machine is that it can help to ensure consistent quality in your nail production. By using an accurate nail machine, you can control the speed, torque, and pressure applied to the nail-making process, which can help to create machine-made nails that are more consistent in terms of size and shape.

This can be important for businesses that rely on nail production for their livelihood, as it helps to ensure that their products meet customer demands.

Safety

Finally, a nail production machine can also be helpful in terms of safety. By using nail machine making, you can avoid the potential for injuries that can occur when using manual methods.

This can help to keep your workers safe and reduce the risk of workplace accidents.

Overall, then, there are many reasons why you might want to consider using a nail pin-making machine. If you are looking for a way to improve your nail production process, a quality nail-making machine may be the solution you need.

If you’re looking for an efficient and reliable nail manufacturing machine, be sure to check out the options available at Awnail.

4. How To Use a Nail-Making Machine

A nail-making machine is an essential piece of equipment for any workshop. It is used to create nails from metal wire.

The nail-making machine consists of a frame, a die, and a punch. The frame holds the wire, the die shapes the nail, and the punch drives the nail out of the die.

This is the proper way of using a common nail-making machine:

Select the Proper Die

The first step in using a nail-making machine is to select the correct size die for the nail you want to make. The die should be about 2 mm smaller than the nail you want to make.

Select the Correct Gauge

Next, select the correct gauge of wire for the die you are using. The gauge of wire is the thickness of the wire in inches.

Cut a Piece of Wire

Finally, cut a piece of wire that is twice as long as the nail you want to make.

Thread the Wire Through the Punch

The nail-making machine is then set up by placing the frame on the bench and securing it in place. The die is placed in the frame and the punch is inserted into the die.

The wire is then threaded through the hole in the punch and around the guide post.

Press Down the Machine

The nail-making machine can now be operated. To make a nail, the punch is pressed down and the machine is rotated. This causes the wire to be drawn through the die and shaped into a nail. The nail is then ejected from the die by the punch.

Now that you know how to use a nail-making machine, you can start making nails at home or in the workshop. Happy crafting!

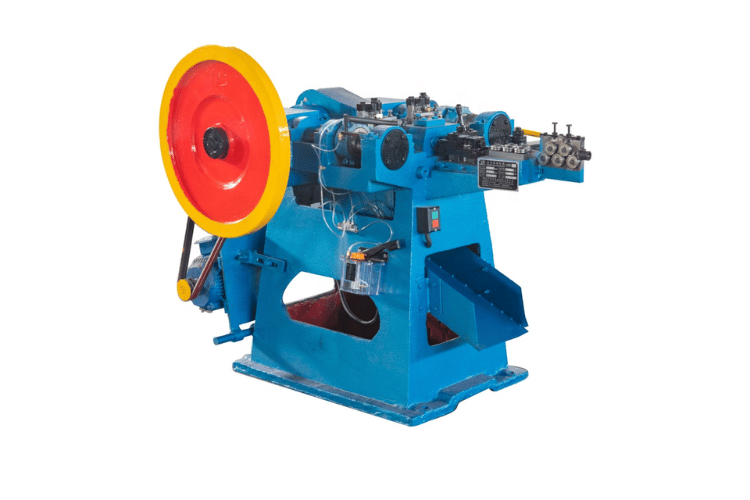

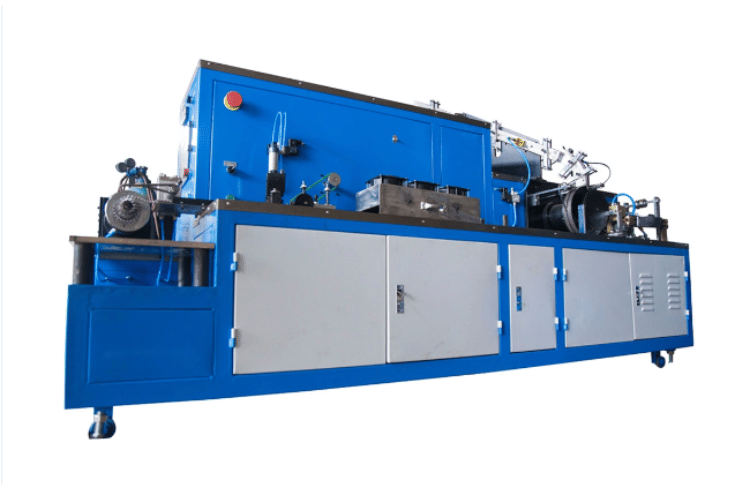

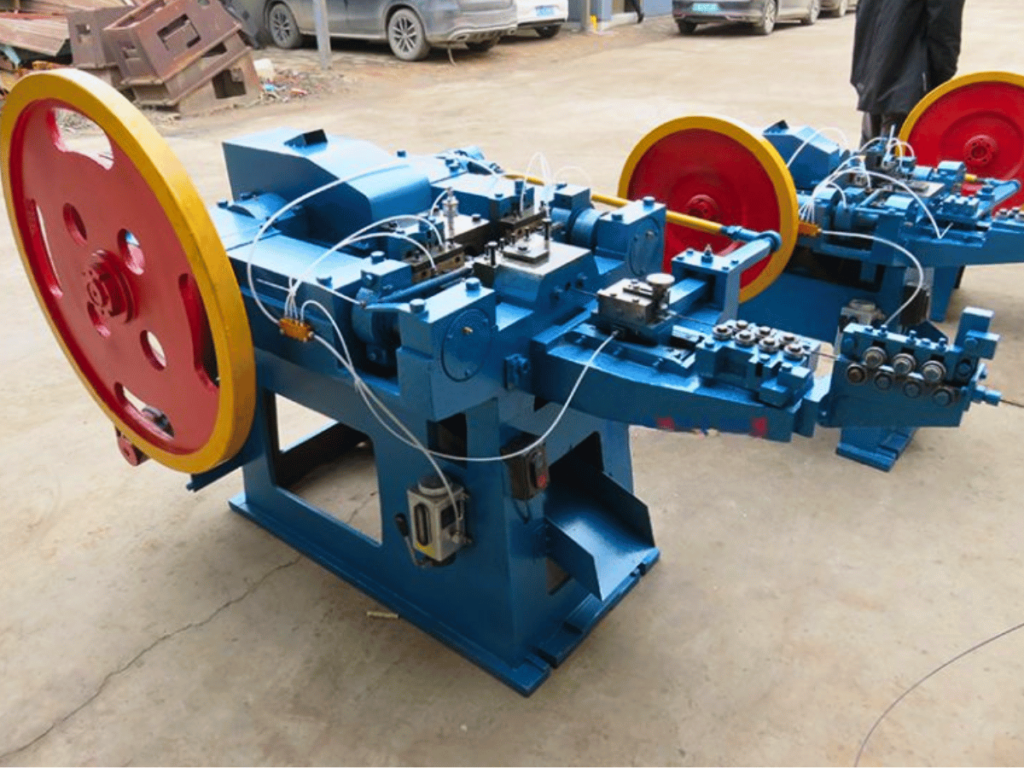

5. Different Types of Nail Making Machines

When it comes to nail-making machines, there are several different types on the market to choose from. Some of the most popular options include:

Hand Operated Nail Making Machines

Hand-operated nail-making machines are another popular option, and they offer a more affordable price point than automatic machines. These machines can still produce a high volume of nails, but they may require more operator input to achieve the desired results.

Pneumatic Nail Making Machines

Pneumatic nail-making machines are another option that is growing in popularity. These machines use compressed air to operate, which makes them very efficient and powerful. They also tend to be very affordable, making them a great option for those on a budget.

Automatic Nail Making Machines

Automatic nail-making machines are some of the most popular options on the market, thanks to their high speed and precision. These machines can churn out large quantities of nails in a short amount of time, making them perfect for industrial applications.

These are just 3 main types of nail-making machines that you may encounter. When choosing the right machine for your needs, it is important to consider the type of nails you will be making, as well as your budget to ensure you get the best possible value for your money.

Except for the main types mentioned above, Awnail also produces

- screw nail making machine

- high speed nail making machine

- nail packing machine

- nail polish making machine

Related reading: Nail Making Machine Project Report

6. Auxiliary Equipment of Nail Making Machine

The auxiliary equipment of the nail-making machine includes nail-making dies, nail mold, nail cutting machine, nail grinding machine, and so on.

Die

The nail-making die is used to form the nail head.

Mold

The nail mold is used to produce the nail body.

Cutting Machine

The nail cutting machine is used to cut off the excess material of nails.

Grinding Machine

The nail grinding machine can be used to grind the nails into different shapes. With this auxiliary equipment, the quality and efficiency of the metal nail-making machine can be improved.

7. 3 Tips for Choosing the Best Nail-Making Machine for Your Needs

When it comes to nail-making machine suppliers, there are a few things you need to take into account before making your purchase. Here are some tips to help you choose the best nail-making machine for your needs:

#1 Consider the Type of Nails

There are different types of nail-making machines available, so you need to consider the type of nails you need to make.

If you need to make regular nails, then a standard nail-making machine will be suitable.

#2 Consider the Size

Nail-making machines come in different sizes, so you need to choose one that is suitable for your needs. If you have limited space in your workshop, then you’ll need a nail-making machine that is small and compact.

However, if you have plenty of space, then you can opt for a larger nail making machine.

#3 Use Search Engines

Search engines are powerful tools that will allow you to find the best wire nail-making machine for your needs. But you should watch out for the advantages of sales contact before you install based on the offer.

Here are some of the keywords you can use to find the perfect wire drawing machine:

- nail-making machine for sale

- concrete nail-making machine

- nail machines for sale

- nail factory machine

- metal nail-making machine

- small nail-making machine

- high-quality nail making machine

8. 4 Tips for Maintenance and Troubleshooting for Nail Making Machines

There are a few tips that you can follow to help maintain your nail making machine and troubleshoot any issues that may arise.

Here is an overview of some maintenance tips for nail making machines!

| No. | Tips |

|---|---|

| 1 | Clean and Lubricate the Machine |

| 2 | Check the Nail Size |

| 3 | Adjust the Position of the Nail Holder |

| 4 | Contact the Manufacturer for Help |

#1 Clean and Lubricate the Machine

Always make sure to properly clean and lubricate your machine after each use. This will help to keep it running smoothly and prevent any damage.

#2 Check the Nail Size

If you notice that your machine is not producing nails correctly, check the nail size adjustment screw to make sure it is set properly. Also, be sure to adjust the nail depth as needed.

#3 Adjust the Position of the Nail Holder

Third, if the nail head is not coming out of the nail holder correctly, you may need to adjust the position of the nail holder.

#4 Contact the Manufacturer for Help

Finally, if you are having trouble with the motor or any other component of the machine, contact the manufacturer for help. They will be able to troubleshoot the issue and provide any necessary repairs or replacements.

Following these tips should help you keep your nail making machine running smoothly and efficiently.

9. Conclusion

Nail making machines come in all shapes and sizes, so it’s important to choose the right one for your needs.

We hope this blog post has helped you understand the different types of nail making machines and which is best for your business. If you have any questions, don’t hesitate to contact us at Awnail. We would be happy to help!

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us