How Awnail Helped Mr. Anderson Achieve 30% More Efficiency

Introduction

Mr. Anderson embarked on a transformative journey with Awnail, integrating advanced automation and precision technology into their nail manufacturing processes. This partnership not only addressed their immediate challenges of outdated manual operations but also positioned them into a new era of efficiency and competitiveness.

In a quest to redefine the efficiency and standards of nail manufacturing, Mr. Anderson turned to Awnail. Faced with the challenge of outdated and labor-intensive production processes, he knew that conventional methods wouldn’t cut it for his ambitious vision. His pursuit of excellence and innovation led him to seek a partner who could not only understand his vision but also bring it to life with cutting-edge technology.

Client: Mr. Anderson, the visionary founder of Precision Nails, LLC, with a passion for elevating nail manufacturing.

Current Problem: Mr. Anderson faces challenges with outdated and manual nail manufacturing processes that compromise efficiency and quality.

Demand: Mr. Anderson required a state-of-the-art solution that could automate the entire nail production process, ensuring not just speed and efficiency, but also consistency and quality. He sought machinery that was not only technologically advanced but could also adapt to their specific production needs.

Current Situation of Customer Company

Mr. Anderson, the visionary founder of Precision Nails, LLC, encountered a critical bottleneck in its production capabilities. Traditional, labor-intensive methods of nail manufacturing not only slowed down production but also led to inconsistent quality. This inefficiency became a glaring issue as the company aimed to scale operations and meet growing market demands.

Moreover, the reliance on manual labor for repetitive tasks led to high operational costs, putting Precision Nails at a disadvantage against competitors who had begun to embrace automation. As a result, Precision Nails found itself at a crossroads, needing to make a significant shift towards modernization to maintain its competitive edge and fulfill its growth ambitions.

In-Depth Investigation for Demands

A thorough investigation by Awnail revealed Precision Nails’ urgent need for a technological overhaul. We discovered that the company needs machinery that could not only automate the entire nail manufacturing process but also ensure precision and consistency in production. This insight led us to tailor a solution that matched their specific demands, focusing on robotics and precision engineering.

The investigation also highlighted the need for flexible production lines that could quickly adapt to changes in product specifications and market demand. By understanding these nuanced requirements, Awnail was poised to provide a comprehensive solution that addressed not just the immediate production challenges but also set the stage for future innovation and scalability.

What Did We Do?

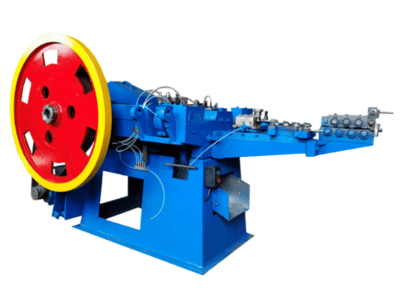

Implemented Robotics-Controlled Nail Making Machines: These advanced units automated the nail production process, from feeding raw materials to packaging finished products, reducing manual intervention.

Integrated Precision Technology: Ensured that each nail produced met quality standards, significantly reducing the rate of defects and rework.

Customized Production Lines: Designed to match Precision Nails’ specific production needs, allowing for scalable output that could grow with their business demands.

Streamlined Supply! Elevated Projects!

30% Uplift in Production Efficiency: Our innovative solutions streamlined operations, enabling Precision Nails to accelerate production while enhancing consistency across the board.

25% Reduction in Labor Costs: The shift towards automation drastically reduced the reliance on manual labor, yielding significant savings that positively affected the company’s profitability.

30% Price Competitiveness Increase: Enhanced production capabilities enabled Precision Nails to introduce competitive pricing strategies, maintaining profit margins while fostering significant business growth.

Testimonial

“Partnering with Awnail has significantly transformed my business operations at Precision Nails. Their cutting-edge, automated solutions not only streamlined our production process but also unlocked new levels of efficiency and quality we hadn’t thought possible. Awnail didn’t just supply us with machines; they equipped us for the future. A huge thanks to the Awnail team for their support and innovation.”