Exceptional Steel Nail Making Machine For Your Business

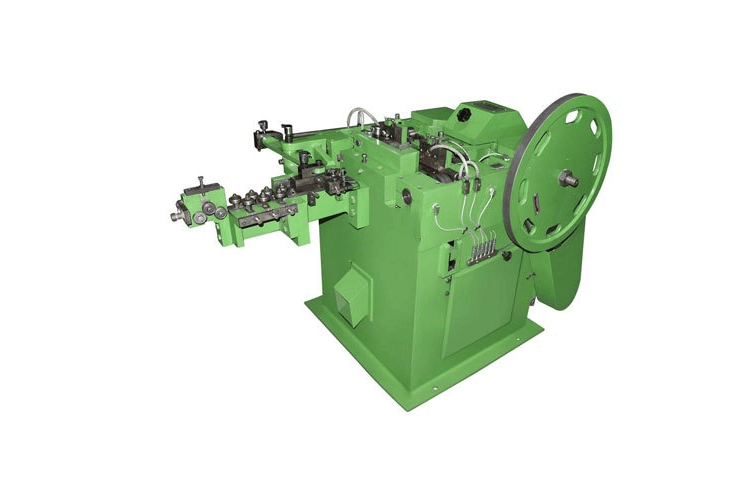

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Features and Benefits of Steel Nail Making Machine

Features of Steel Nail Making Machine

High-Speed Production

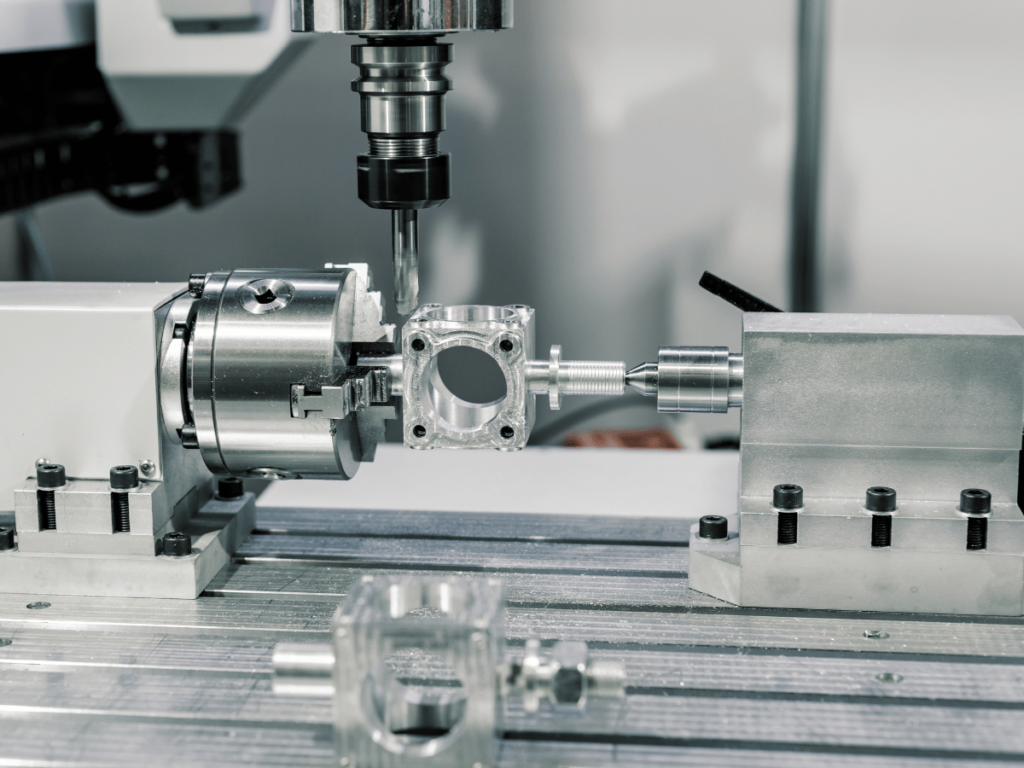

Precision Engineering

Durability and Low Maintenance

Benefits of Steel Nail Making Machine

Enhanced Product Quality

Adaptability to Various Nail Types

Safety in Operation

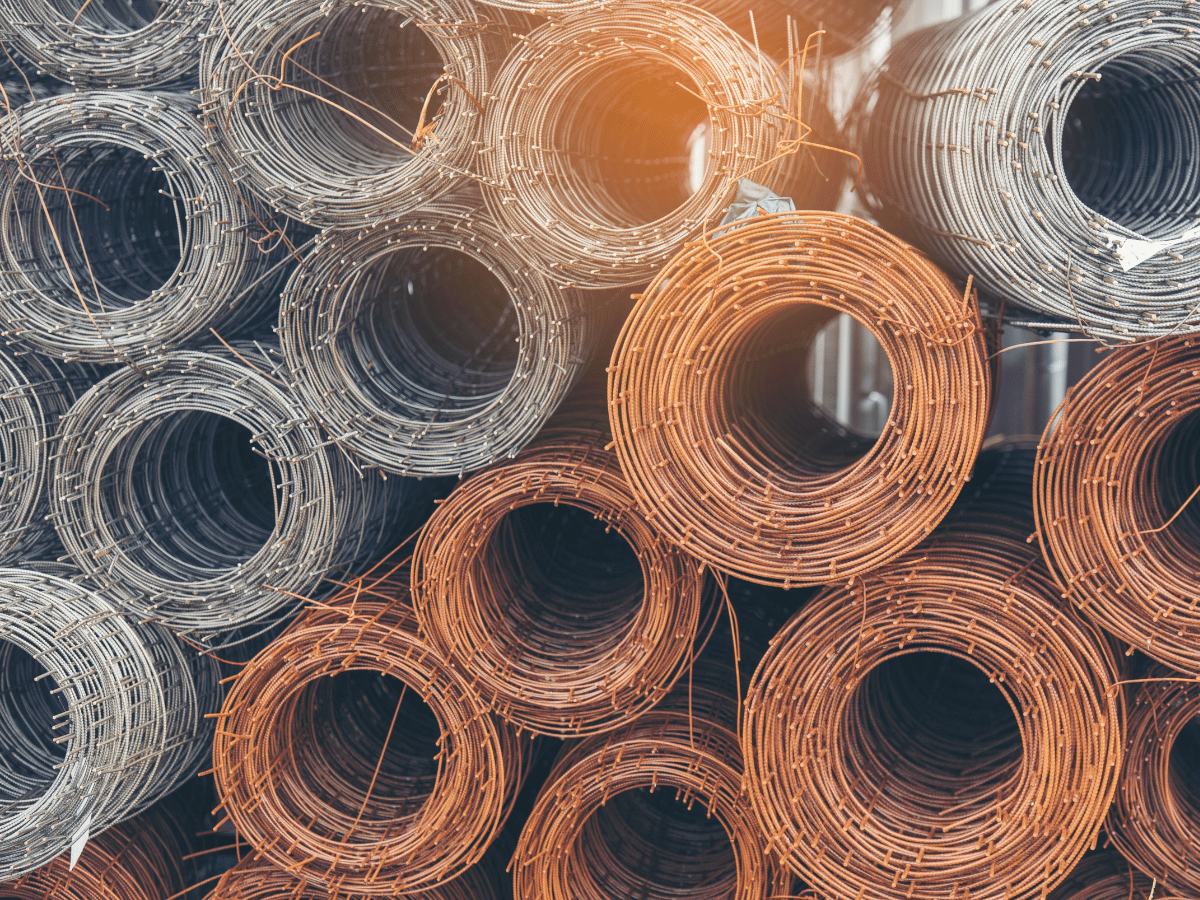

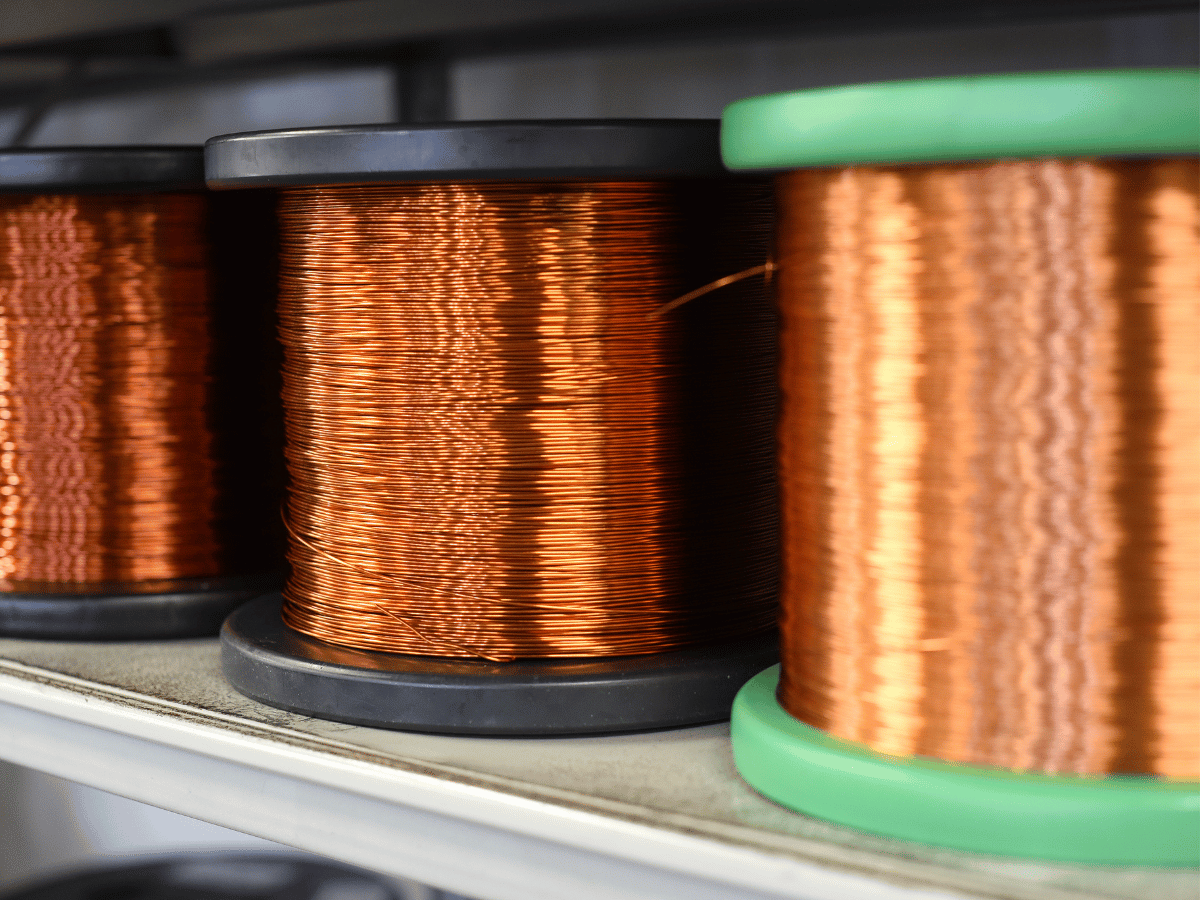

Raw Material of Steel Nail Making Machine

Steel Wire

Wire Coils

Coating Materials

Steel Nail Making Machine Price

Applications of Steel Nail Making Machine

Construction Industry

Shipping Pallet Production

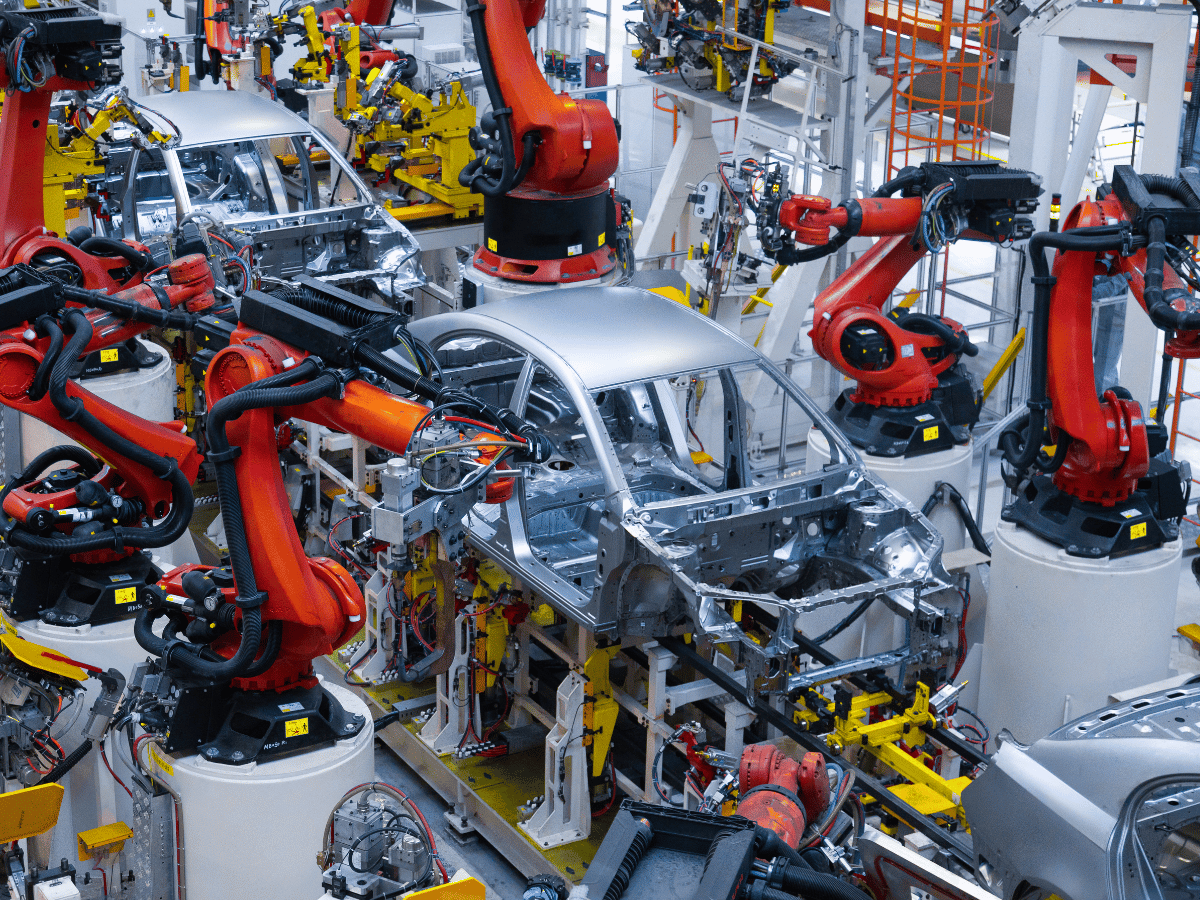

Automotive Industry

3 Considerations When Buying Steel Nail Making Machine

#1 Production Capacity (e.g., 5000 Nails per Minute)

#2 Nail Length Customization Options

#3 Supplier Reputation

Dive Deeper Into Our Resources

Everything You Need to Know About Steel Nail Making Machine

If you’re in the business of making nails, you need a steel nail-making machine. But what are the different types of machines and which one is right for you?

Nail-making machines are a key part of any manufacturing operation that produces nails. There are many different types and sizes of nail-making machines, so it’s important to know what to look for when purchasing one.

In this article, we will discuss the different types of nail-making machines and the features you should look for when purchasing one. We will also cover the cost of owning a nail-making machine and how to properly maintain it. Let’s get started!

1. What Is a Steel Nail Making Machine

Steel nail-making machines are used to create steel nails. They are typically made of steel or iron and use a hammer to strike a nail blank into a nail head. The machines can be powered by electricity, gas, or hydraulics. Steel nail-making machines can also be used for other types of nails, such as wood screws and bolts.

These machines are designed to create steel nails in a variety of shapes and sizes; some steel nail-making machines even have multiple heads that allow them to produce different types of steel nails at once.

These steel nail-making machines are typically used in construction projects and industrial settings, but some steel nail-making machines can be used for domestic purposes as well. The steel is heated and then forced through a die under pressure which shapes it into the desired nail.

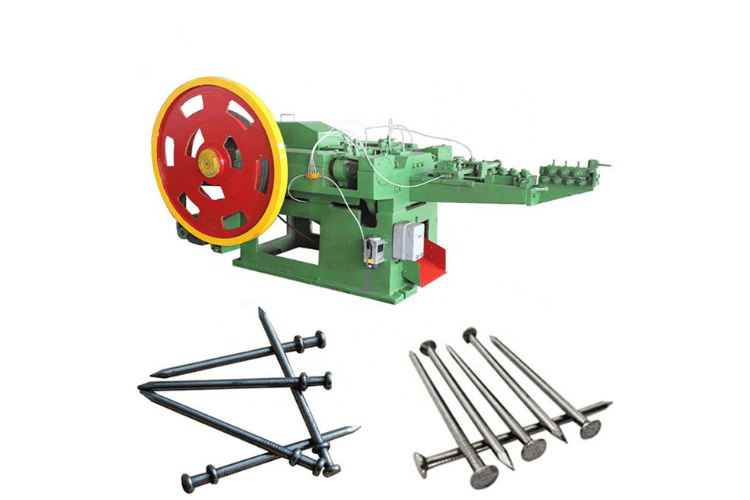

2. Different Types of Steel Nail Making Machines

There are numerous steel nail-making machines available in the market today. They vary concerning their size, shape, and design. You have to choose the steel nail production machine based on your requirement and budget.

Here are some steel nail making machine types that we provide:

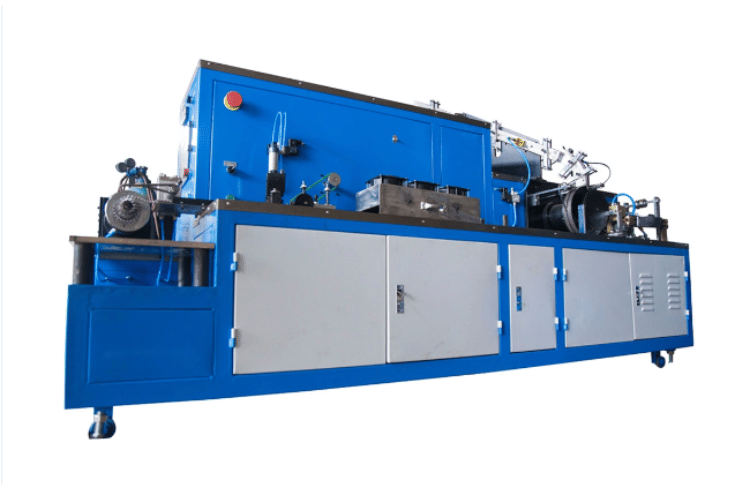

High-Speed Steel Nail Making Machine

This steel nail machine is designed for high production. It can make steel nails with a diameter of 2mm to 6mm and a length of 20mm to 150mm. The machine operates at a speed of 3000 nails/minute. It is suitable for small and medium size factories.

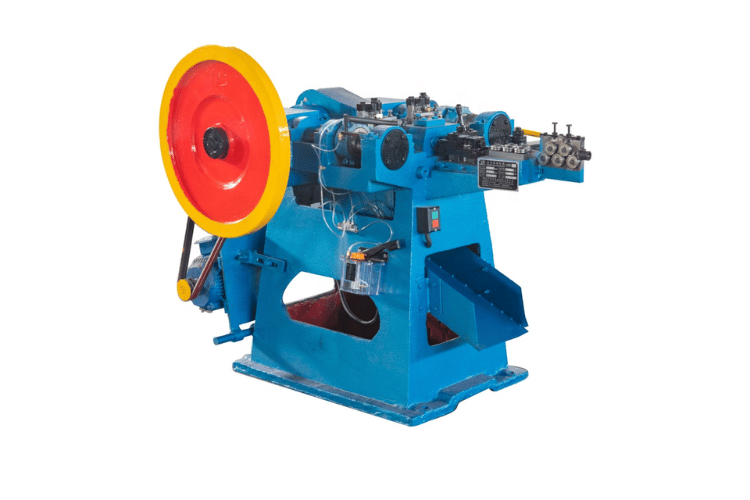

Automatic Steel Nail Making Machine

This steel nail machine is fully automatic. It is made with a steel frame, which makes it strong and durable. As well as this, the steel nail-making equipment also has an aluminum alloy casting solid body for added durability and strength.

The steel nails are produced with high precision so they can be used in all types of construction projects without any hassle. The steel nails can be produced with a diameter of 0.89mm to 12mm and a length ranging from 25 mm to 150 mm.

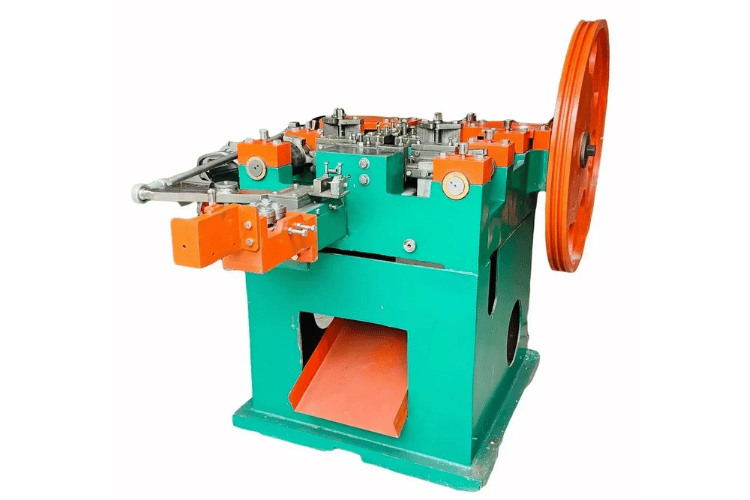

Manual Steel Nail Making Machine

This steel nail-making machine is manual. It can make steel nails with a diameter of 0.75mm to 12mm and a length of 20mm to 150mm. The machine has an adjustable feeding system. It is suitable for small size factories.

So, these are the different types of steel nail-making machines that are available in the market today. You need to choose the steel nail-making machine based on your requirement and budget.

3. How To Choose the Right Steel Nail Making Machine for Your Needs

When looking for a steel nail-making machine, it is important to consider what your needs are. There are many different machines available on the market, so it is important to find the one that is right for you.

Some factors to consider when choosing a steel nail making machine include:

The Size of the Machine

The size of the machine is an important consideration when choosing a steel nail-making machine. Machines come in different sizes, so it is important to find one that is the right size for your needs. If you have a small shop, you will need a smaller machine. If you have a large shop, you will need a larger machine.

The Type of Steel Nails That the Machine Can Make

There are many different types of steel nails, so it is important to find one that can make the type of nails you need. If you need iron nails, then you will need an iron nail-making machine that is designed to make iron nails. If you need steel nails, then you will need a machine to make steel nails.

Iron Nails Making Machine is almost the same as steel nail making machine, the difference is that the former can make iron nails while the latter can only make steel nails.

The Speed of the Machine

Some machines are faster than others, so it is important to find one that is fast enough for your needs. If you need a machine that can make a lot of steel nails quickly, you will need to find one that is fast.

The Price of the Machine

Steel nail making machine price is different, some machines are expensive while others are cheap. You need to find a steel nail-making machine that is affordable for you without compromising on quality.

The Quality of the Nails Made by the Machine

Some machines make higher quality nails than others. If you need a machine that makes high-quality nails, you will need to find one that is made well.

If you are not sure what machine is right for you, consult with a steel nail-making machine manufacturer to get help finding the right machine for your needs.

Awnail is one of the steel nail manufacturing machines in China, that can help you find the machine for your needs.

Contact us at Awnail to learn more about steel nail-making machines and how we can help you find the right one for your needs!

4. Benefits of Using a Steel Nail Making Machine

There are many benefits of using a steel nail-making machine. Some of the key benefits include:

Increased Efficiency

A steel nail-making machine can produce nails much faster than someone could by hand. This means that you can get your work done more quickly, which can save you time and money.

Consistent Quality

By using steel nail-making machines, you can ensure that all of your nails are produced with the same quality. This will make it easier to build or repair structures because the nails will fit together much more easily.

Save Money

Because steel nail-making machines are so efficient, you can save money on steel and labor costs. The steel nails themselves will also be cheaper because the machine produces them more efficiently than a person could by hand.

Time Saving

As mentioned above, steel nail-making machines can save you time. This is important when it comes to steel nail production because steel is a valuable commodity and time equals money.

Customization

Steel nail-making machines allow you to customize your steel nails with the color, size, and shape that you want. This means that they can be produced in any way that suits your needs best.

Useful for Everyone

Steel nail-making machines can be used by anyone, regardless of their experience level or skill set. This means that steel nail production is not limited to professionals in the steel industry.

All of these benefits make steel nail-making machines a valuable tool for any business or individual. If you are looking for a way to improve your efficiency and quality, then a steel nail-making machine is the perfect solution.

5. How To Operate a Steel Nail Making Machine

Operating a steel nail-making machine is not as difficult as it may seem. The following are the basic steps you need to take to run the machine:

Step#1 Check Power

You should ensure that there is power in the steel nail-making machine. This is important because if you have a sudden power outage, you will be stuck without any nails to make. The steel nail-making machine uses a lot of electricity so it needs to be able to function properly at all times.

Step#2 Fill the Hopper

The hopper is the part of the steel nail-making machine that holds the nails. You will need to fill it with nails before you can start making them. The number of nails you put in will depend on the size of the nails you are making. Be sure to use the right type of nails for your machine or they may not work properly.

Step#3 Turn on the Machine

Once you have filled the steel nail-making machine, turn it on and wait for it to heat up. When it has heated up enough, start feeding nails into the hopper one at a time. You should use either your hand or foot to push them through as this will help to keep the machine running smoothly.

Step#4 Wait for the Nails to be Made

It will take a few minutes for the steel nails to be made. Once they are done, they will come out of the other end of the machine. Be sure to remove them quickly so that they do not cool down and become unusable.

Step#5 Repeat as Necessary

You can repeat this steel nail-making process whenever you need to make more steel nails. The steel nail-making machine will work just as well each time and produce high-quality steel nails for your construction projects or crafts.

Step#6 Turn off the Machine

Once you have finished making steel nails, it is time to turn off the steel nail-making machine. This should be done by pressing a button on its front panel or by using an external switch. The steel nail-making machine will then cool down and can be turned back on whenever you need it again.

This steel nail-making machine is very easy to use. All you have to do is follow the steel nail-making process outlined above and you will be able to make steel nails whenever you need them. The steel nail-making machine will not only produce high-quality steel nails but also is very easy to use.

6. Components of a Steel Making Machine

Steel-making machines are composed of several different components, each of which plays an important role in the production of steel.

Some of the key components of a steelmaking machine include:

Furnace

The furnace is the heart of the steel-making machine, providing the heat necessary to melt the steel. It is typically made from refractory steel and steel-clad steel, which can withstand the high temperatures that steel production requires.

Ladle

The ladle is where steel is stored after it has been melted in the furnace. It is typically used for both storage and transportation of steel, although some steel-making machines use a separate vessel for transporting molten steel from one area to another.

Tundish

The tundish is a steel container that steel passes through on its way to the steel-making reactor. It acts as a reservoir, allowing liquid steel to be added gradually to the steelmaking process to avoid overflowing and damage.

Steelmaking Reactor

The steelmaking reactor takes control of steel once it has passed through the tundish; steel is added to the steelmaking reactor, where it undergoes various processes to remove impurities and create high-quality steel.

Casting Wheel

The steel-making machine then passes through a casting wheel on its way to being cooled down and hardened into steel products.

Cooling Bed

Finally, steel is transferred onto a cooling bed so that it can cool down and harden into steel products. Once the steel has cooled, it is ready to be used for a variety of steel-making applications.

Each of these components plays a critical role in the steelmaking process and must be functioning properly for steel to be produced.

7. Process of Manufacturing Nails With a Steel Nail Making Machine

Manufacturing nails with a steel nail-making machine is a process that involves several steps.

Here are the steps involved:

Step#1 Steel Wire Feeding

The steel wire nail-making machine will have a steel wire reel that is loaded onto the spindle shaft. This steel wire reel can be attached to an automatic steel wire feeding system through which it gets fed automatically into the steel nail-making machine.

Make sure that you check if there are enough nails in the hopper before starting the steel wire feeding process.

Step#2 Wire Cutting

The steel wire that is fed into the machine will be cut to the desired nail length by a set of rotating knives. These knives are also responsible for shaping the nails into their finished form.

Step#3 Heating

Once the nails have been cut and shaped, they are transferred to the heating furnace. This steel nail-making machine has a heating furnace that is electrically heated. The nails will be heated until they attain their red hot state at which point they can easily be molded into their desired shape.

Step#4 Heading

After the steel wire has been cut and heated, it is then transferred to the heading die. The steel nail-making machine will have several headed dies that will be used to give the nails their desired head shape.

Step#5 Cooling

The final step in the steel nail-making process is to cool the nails. This can be done by transferring them to a cooling bed or through air quenching. The cooled nails will then be ready for packaging and shipping.

Making nails with a steel nail-making machine is a process that involves several steps. This steel wire nail making machine is highly efficient and is capable of producing huge volumes of nails within a short period.

Here’s a video showing the steel nail making machine in action!

8. Safety Considerations When Using a Steel Nail Making Machine

When using a steel nail-making machine, several safety considerations need to be taken into account.

Here is an overview of some of the safety considerations that need to be made when using a steel nail-making machine:

| No. | Description |

|---|---|

| 1 | Wear safety goggles to protect your eyes from flying debris. |

| 2 | Wear a dust mask to protect your lungs from the dust created by the steel nail-making machine. |

| 3 | Make sure that the steel nail-making machine is properly grounded before use. |

| 4 | Do not operate the steel nail-making machine if you are tired or under the influence of drugs or alcohol. |

| 5 | Keep children and pets away from the steel nail-making machine while it is in use. |

| 6 | Always unplug the steel nail-making machine when not in use. |

- Wear safety goggles to protect your eyes from flying debris.

- Wear a dust mask to protect your lungs from the dust created by the steel nail-making machine.

- Make sure that the steel nail-making machine is properly grounded before use.

- Do not operate the steel nail-making machine if you are tired or under the influence of drugs or alcohol.

- Keep children and pets away from the steel nail-making machine while it is in use.

- Always unplug the steel nail-making machine when not in use.

Following these steel nail-making, machine safety considerations will help ensure a safe and injury-free experience when using this type of machinery.

9. 5 Tips for Maintaining Your Steel Nail Making Machine for Optimal Performance

Maintaining your steel nail-making machine is important for optimal performance. Here are some tips to help you keep your machine in good condition:

#1 Keep Steel Nail Making Machine Lubricated

You should always keep the steel nail-making machine well-lubricated with oil or grease to minimize friction resistance and prevent rusting, which may lead to damage of parts. Add some grease on the steel nails that are used during steel nail production so they don’t get damaged by dust.

If steel nails are not properly greased up during the steel nail-making process then these can rust which may lead to the weakening of their strength.

#2 Keep the Machine Clean and Free of Debris

It is important to keep your steel nail-making machine clean and free of debris to prevent damage and ensure optimal performance. Make sure to remove any built-up dust or metal shavings from all parts of the machine regularly.

Also, be sure to clean the steel nails before welding them together to remove any debris or dust that may have accumulated. This will help ensure a strong and lasting weld.

#3 Inspect the Steel Nails for Defects

It is important to inspect the steel nails for any defects before using them in your steel nail production process. Make sure that all of the nails are straight and have no cracks or chips in them.

Damaged nails may not hold up under the stress of steel nail production and could potentially cause damage to the machine.

#4 Keep Steel Nail Making Machine Properly Calibrated

It is important to keep your steel nail-making machine properly calibrated to ensure accurate steel nail production. Regularly check the calibration of all machines and adjust them as needed.

#5 Store Steel Nails in a Safe Place

It is important to store steel nails in a safe place where they won’t get damaged or lost during steel nail production. It can be helpful to use containers with labels so that you know which steel nails go into which steel nail production machine.

By following these tips, you can help keep your steel nail-making machine in good condition and ensure that it performs at its best.

10. Conclusion

This article has gone through all the necessary steps to help you figure out if steel nail-making machines are right for your company. We hope that this guide has helped provide direction and allowed you to make an informed decision about whether or not these tools can be beneficial in producing high-quality nails at a competitive price.

If you need further assistance with determining which machine is best, please don’t hesitate to contact us at Awnail.

Ready for Change? Take Action with Our Wire Concrete Coil Steel Iron Screw Roofing Nail Making Machine

Connect with Us