Exceptional High Speed Nail Making Machine For Your Business

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Features and Benefits of high speed nail making machine

Features of High-Speed Nail Making Machine

Increased Production Speed

Advanced Automation

Energy Efficiency

Benefits of High-Speed Nail Making Machine

Enhanced Quality Control

Flexibility in Production

Improved Workplace Safety

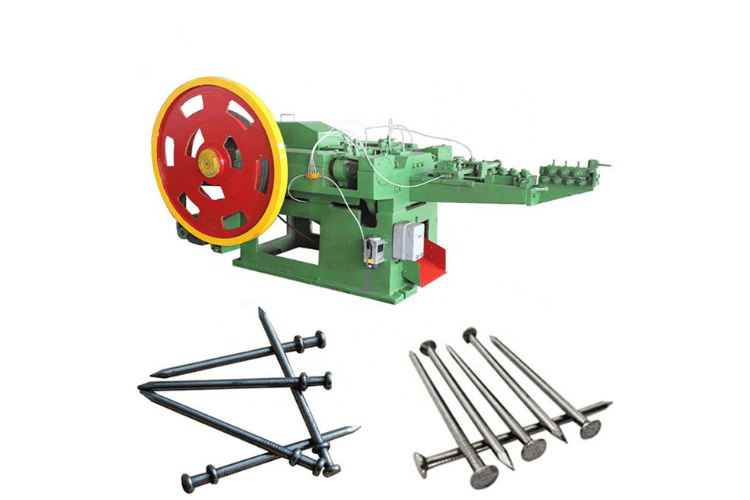

Types of High Speed Nail Making Machine

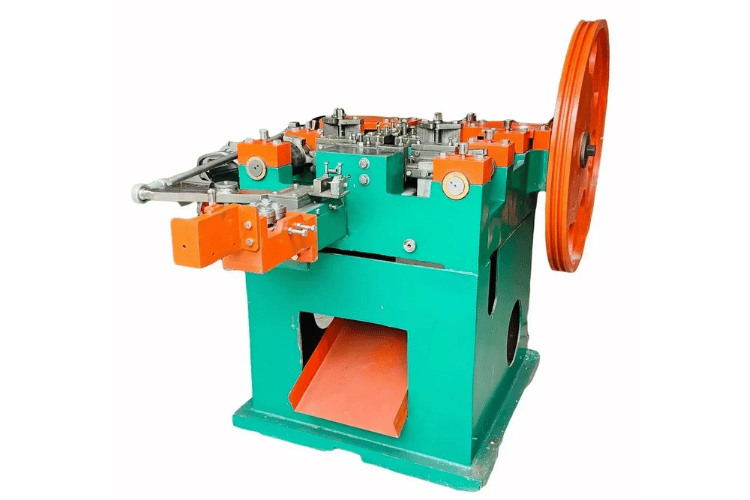

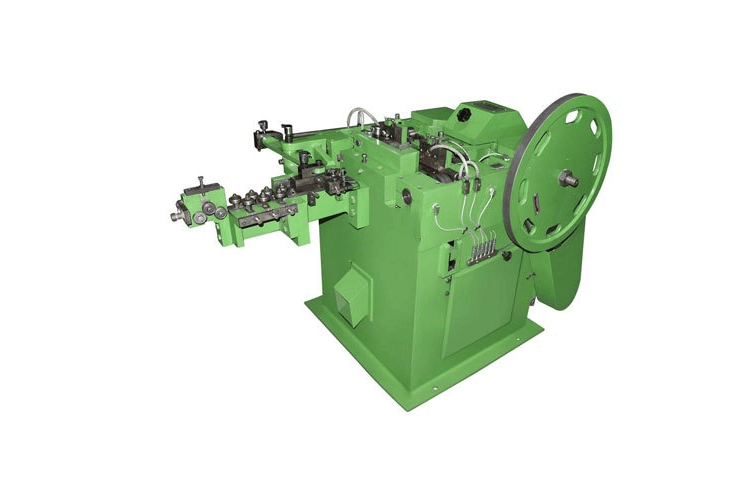

High Speed Automatic Wire Nail Making Machine

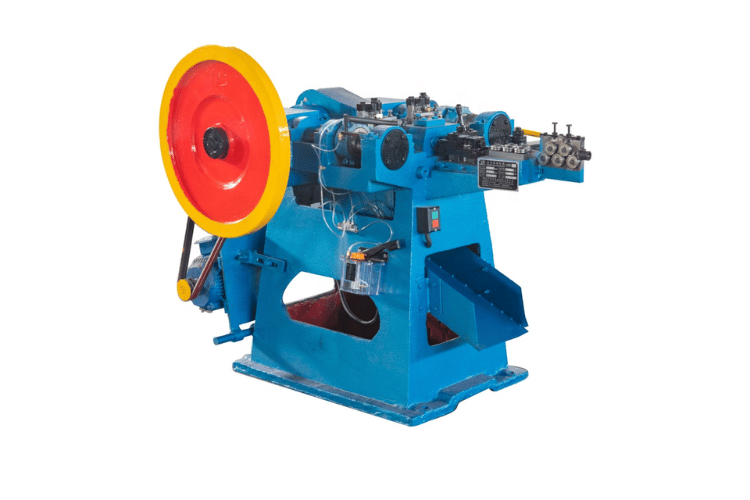

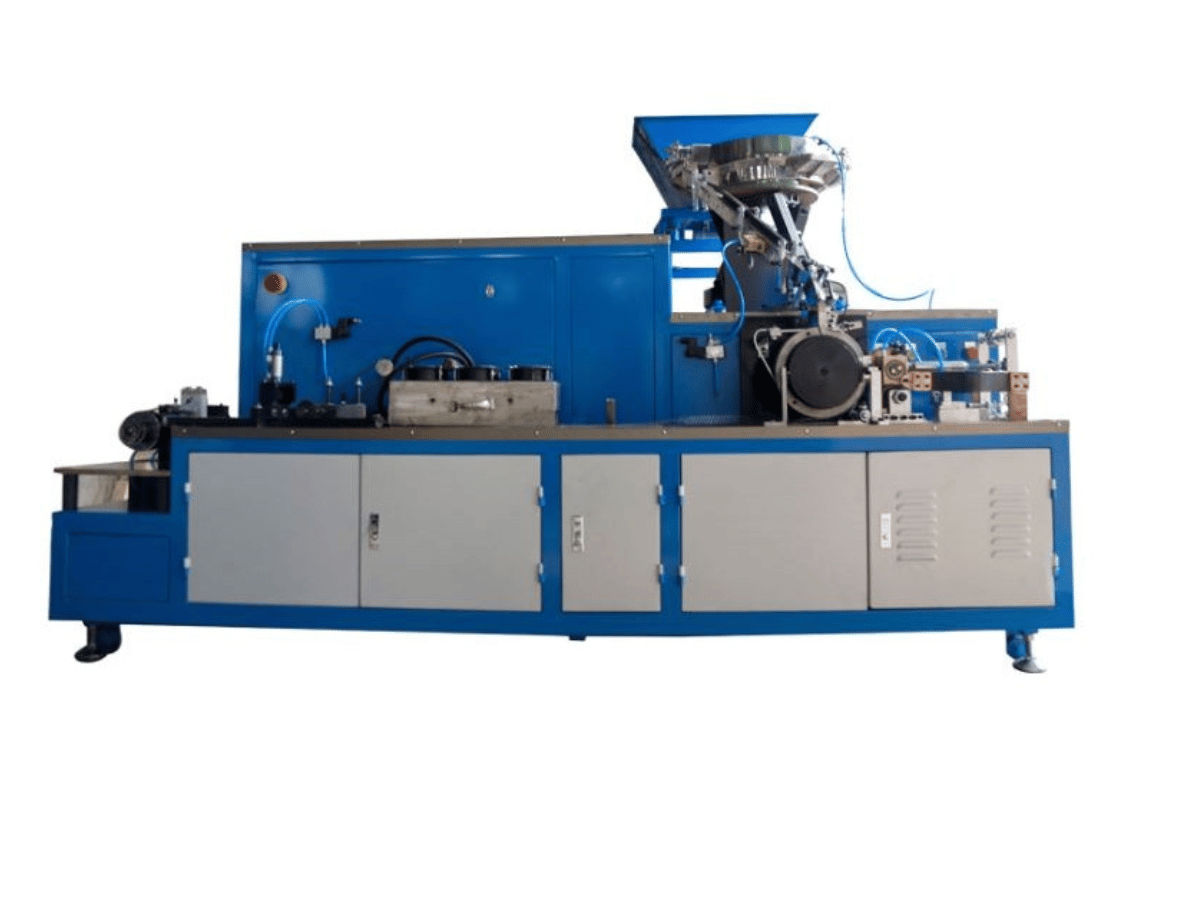

High Speed Coil Nail Making Machine

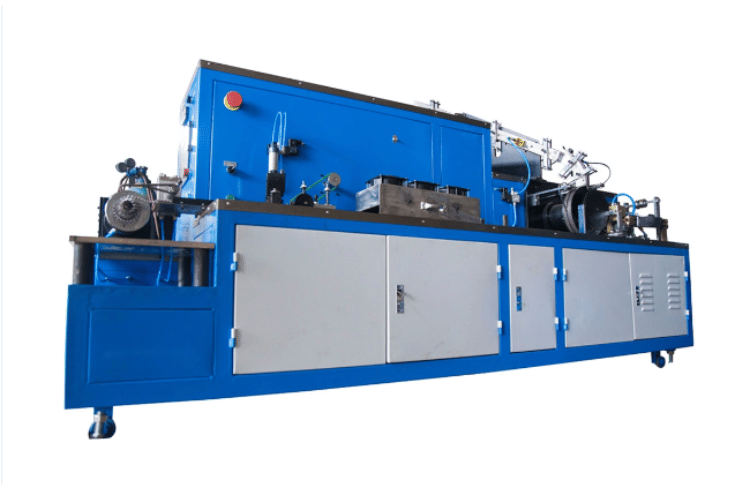

High Speed Brad Nail Making Machine

High Speed Nail Making Machine Price

Applications of High Speed Nail Making Machine

Building and Construction Industry

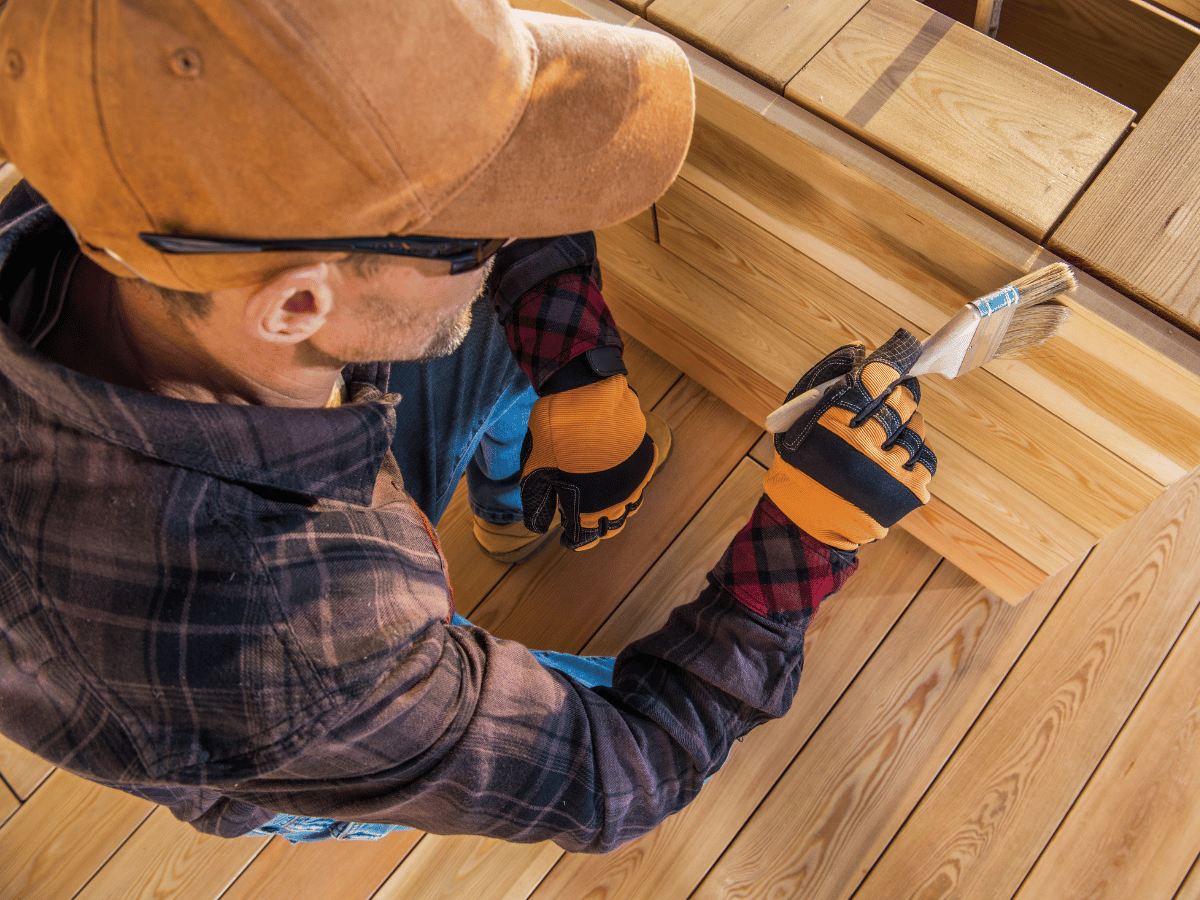

Furniture Manufacturing

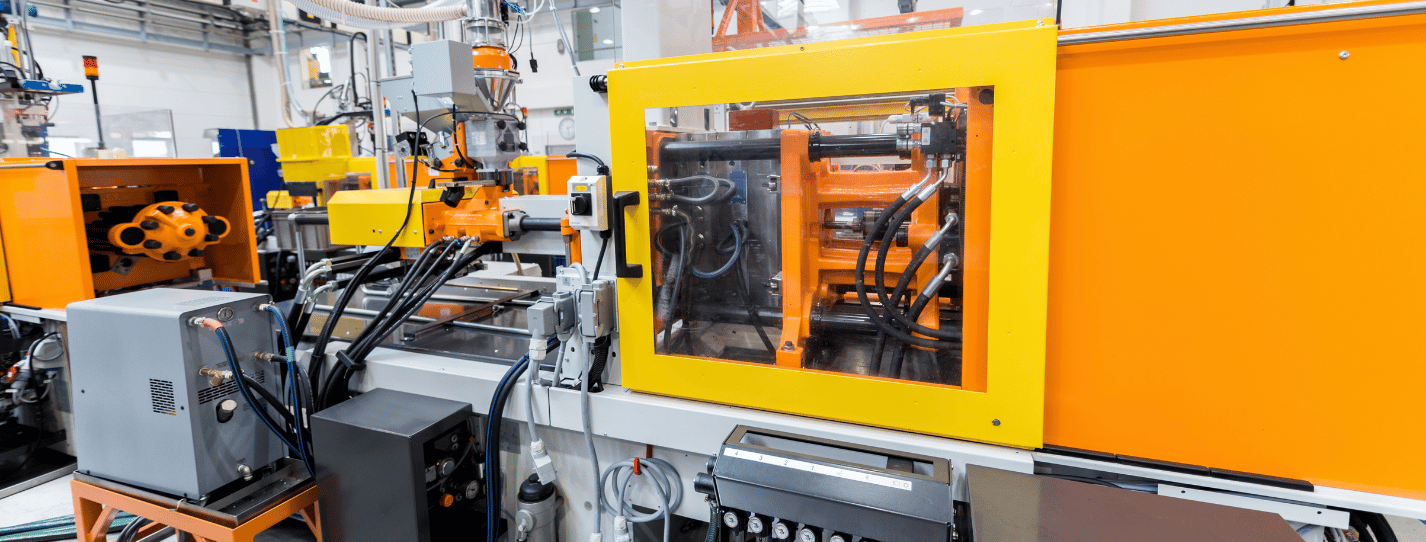

Automotive Industry

3 Considerations When Buying High Speed Nail Making Machine

#1 High Output Rate: 500-700 Nails/Minute

#2 High-Grade Alloy Construction and Simplified Maintenance

#3 Precision and Quality of Nails

Dive Deeper Into Our Resources

- 9 Essential Features to Consider When Buying a High-Speed Nail Making Machine

- Transforming Nail Production: A Guide to High-Speed Machine Integration

High Speed Nail Making Machine: How It Works and What Makes It So Fast

In the business of manufacturing, time is money. That’s why a high speed wire nail making machine is so sought after – they can produce nails at lightning speeds, flexible settings, saving manufacturers time and money.

When it comes to making things quickly, there’s no machine quite like the high-speed nail-making machine. But how do these machines work and what makes them so fast? Read on to find out!

In this post, we’re going to take a look at how it works and explore what makes it so fast. By the end of this post, you’ll have a good understanding of why this machine is so popular with businesses.

1. What Is a High Speed Nail Making Machine

A high-speed nail-making machine is a device that is used to quickly and efficiently create nails. They are commonly used in factories and other industrial settings, where high volumes of nails are needed.

The high-speed nail-making machine consists of several different parts. The main components are:

- Nail Head Die – which is a nail cutter and is responsible for shaping the nails.

- Feeder System – that delivers the wire to the die.

- Quench Tank – that cools and hardens the nails.

One of the benefits of using a high-speed nail-making machine is that it can produce nails at a high rate of feed speed. This allows companies to meet demand quickly and efficiently.

Additionally, high-speed machines are typically more accurate and consistent than hand-made nails.

If you are looking for a high-speed nail-making machine, there are several different options available on the market. Make sure to contact our Awnail team for assistance.

2. How Does a High Speed Nail Making Machine Work

High speed wire nail making machine comes in a few different types, but they all have one goal in mind – to quickly and efficiently produce good quality nails. The steps involved in how a high-speed nail making machine works are as follows:

Step #1: The metal sheet is placed into the machine.

Step #2: The nail head is cut out of the sheet.

Step #3: A hole is punched in the top of the nail head.

Step #4: The nail shank is cut from the sheet.

Step #5: The nail point is sharpened.

The high-speed nail-making machines use a variety of common nail making machine methods to create nails as well. The most common method is to use:

- Series of rotating hammers that strike a blank disk into the wire feeding system, creating nails in all shapes and sizes.

- Other high-speed machines may use lasers or water jets to create ordinary wire nails.

No matter the method, high-speed machines can create nails much faster than most traditional nail making machine. This makes them ideal for high-volume production environments.

If you’re looking for a high-speed nail-making machine, be sure to consult with an experienced manufacturer like Awnail. They can help you choose the right machine for your needs at a low high speed nail making machine price and ensure that it is set up for optimal performance.

Here’s a video of high speed nail making machine in action!

3. What Makes the High Speed Nail Making Machine Super Fast

The high speed wire nail machine is super fast because it can produce nails at a rate of up to 1000 nails per minute. This high speed allows for a high production rate, which means that the machine can produce a large number of nails in a short amount of time.

Additionally, the high speed also ensures that the nails are consistent in size and shape, which results in a high-quality product. There are a few factors that make the high speed nail machine super fast. These are:

High-Powered Motor

The first is the high-powered motor that drives the machine frame nail-making process. This motor can create high speeds and pressures, which results in nails that are efficiently made.

Design of the Machine

Additionally, the design of the high speed wire nail making machine allows for quick and easy changes of the nails, which minimizes downtime.

Proven Reliability

Finally, the high-speed nails making machine has been rigorously tested and proven to be reliable, meaning that it can handle high production volumes without issue.

4. Benefits of Using a High Speed Nail Making Machine Over Other Types

When it comes to making nails, there are a few different ways to do it. One of the most popular methods is by using a high speed wire nail making machine. There are several benefits to using this type of machine over others. Here are just a few:

Speed

A high-speed nail maker machine is much faster than traditional machines that produce common nails. This means that you can produce more nails in a shorter amount of time.

Accuracy

The high-speed nail wire making machine is much more accurate than traditional machines. This means that your nails will be more consistent in size and shape.

Efficiency

High-speed machines use less energy than traditional machines, which means you can run them for long periods with high reliability, low noise, and without having to worry about your electricity bill.

If you are looking for a high-quality, high-speed nail-making machine in China, then be sure to check out the offerings from Awnail. They offer a variety of machines that are perfect for any business or home workshop. Contact them to learn more!

5. Type of Nails Can Be Produced by a High Speed Nail Making Machine

A high-speed nail-making machine can produce a variety of nails. The following characteristics are the common types of nails that are produced by high-speed machines are:

Wire Nails

Wire nails are the most common type of nails that are produced by high-speed equipment machines. They are made of thin wire that is coiled into a spiral shape and has a different size. Wire nails are often used for construction projects, as they are strong and durable.

Cut Nails

Cut nails are another type of nail that is often produced by a high-speed nailing machine. They are made of thicker wire than wire nails and are shaped like a blade. Cut nails are often used for carpentry projects, as they are strong and can be easily hammered into wood.

Spikes

Spikes are another type of nail that can be produced by high-speed machines. They are made of even thicker wire than cut nails and are shaped like a pyramid. Spikes are often used in construction projects, as they are very strong and can penetrate through tough materials.

Staples

Staples are a type of fastener that is used to join two pieces of material together. They are often made of metal and consist of a thin wire that is bent into a shape that resembles a staple. Staples are often used in upholstery projects, as they hold the fabric securely in place.

6. Factors Should Be Considered Before Purchasing a High Speed Nail Making Machine

When looking to purchase a high-speed nail-making machine, there are a few factors you will want to take into consideration. Here is an overview of some of the most important factors:

| No. | Factors |

|---|---|

| 1 | Speed of Machine |

| 2 | Type of Nails It Makes |

| 3 | Size of the Machine |

| 4 | Customer Service and Warranty |

Speed of Machine

The speed of the machine and its outstanding safety performance are important because you want to be sure that it can make nails quickly enough to keep up with your production needs.

Type of Nails It Makes

The type of nails it can make is also important because you want to make sure that the machine can make the specific type of nails that you need.

Size of the Machine

Finally, this machine comes in different sizes and is important because you want to make sure it is big enough to handle your production needs.

Customer Service and Warranty

It is also important to consider customer service and fully covered warranty coverage when purchasing a high-speed nail-making machine.

Ultimately, you will want to choose a high-speed nail-making machine that meets your specific needs. So, be sure to take all of these factors into consideration before making your purchase.

By considering these factors, business owners can be sure to select the right machine for their needs.

7. How to Operate a High Speed Nail Making Machine

Operating a high-speed nail-making machine can seem daunting at first, but with a little practice, it can be easy to do. Here are the steps on how to operate a high-speed nail making machine:

Step #1: Make sure that the machine is turned off and unplugged before you start.

Step #2: Remove the lid and make sure that the nails are in the correct position.

Step #3: Plug in the machine and turn it on.

Step #4: The machine will start to heat up; wait until it’s at the correct temperature before you start using it.

Step #5: Place the material that you want to nail into the machine’s feeder tray.

Step #6: Hold down the foot pedal to start nailing the raw material.

Make sure to keep your hands and fingers away from the moving parts of the machine, and always unplug the machine when you’re done using it. If you’re looking for high-quality nails, be sure to check out Awnail and their high-speed nail-making machine.

They offer a wide variety of nails in a variety of sizes and styles, so you’re sure to find the perfect nails for your project. Give Awnail a call today to learn more!

8. 5 Tips on How to Maintain a High Speed Nail Making Machine

Nail-making machines are high-speed devices that can produce large quantities of nails in a short amount of time. While these machines are built to be durable and long-lasting, they will require some routine maintenance to keep them running at their best.

Here are some tips on how to maintain your high-speed nail making machine:

#1 Keep the Machine Clean

The machine should be cleaned regularly to prevent the build-up of dust levels and debris. This will help to ensure that the machine runs smoothly and does not cause any damage.

#2 Lubricate the Machine Regularly

The moving parts of the machine will need to be lubricated regularly to keep them running smoothly. Avoiding lubricating oil shortage or low lubrication help to extend the life of the machine.

#3 Check for Damage

Inspect the machine for any damage regularly and fix any problems as soon as possible. Damaged parts can cause the machine to run slower or even stop working altogether.

#4 This Machine Is Not Meant for Other Type of Materials

It is also important to keep in mind that high-speed nail-making machines are not meant for use with other types of raw materials. Attempting to do so could damage the machine and may result in safety hazards.

#5 Read the Instructions

Always be sure to read the manufacturer’s instructions carefully before using your high-speed nail-making machine.

By following these tips, you can help to ensure that your machine runs smoothly and efficiently for years to come and maintain high productivity.

9. Conclusion

This article discussed the inner workings of a high-speed nail machine, as well as some of the reasons why they have high accuracy. It’s important to understand these things if you want to be able to buy one that is right for your business.

You can use this information when buying or selling a used high-speed nail machine, or even just for general knowledge about these types of machines. If you have any questions at all after reading this article, feel free to contact us! We love talking about our products with people who are interested in them.

Ready for Change? Take Action with Our Wire Concrete Coil Steel Iron Screw Roofing Nail Making Machine

Connect with Us